Illumination Systems and Methods for Photoluminescence Imaging of Photovoltaic Cells and Wafers

a photovoltaic cell and photoluminescence imaging technology, applied in the field of illumination systems, can solve the problems of significant light safety issues in the prior art laser-based pl imaging system, extreme intensity of image formed on the retina, and short measurement time, so as to improve the thermal emission of the wafer or cell, the effect of shortening the measurement time and high intensity illumination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058]Preferred embodiments of the invention will now be described, by way of example only, with reference to the accompanying drawings.

[0059]Photoluminescence (PL) imaging is known to be a rapid and convenient technique for characterising silicon ingots, blocks, wafers, as well as silicon-based photovoltaic (PV) cells both during and after manufacture, using systems and methods described in the abovementioned published PCT patent application No WO 07 / 041,758 A1. The PL emission from silicon arises primarily from band-to-band recombination in the wavelength range 900 to 1300 nm, and can provide information on many material, mechanical and electrical parameters of relevance to PV cell performance including minority carrier diffusion length and minority carrier lifetime, and the impact of certain materials impurities and defects on the these properties.

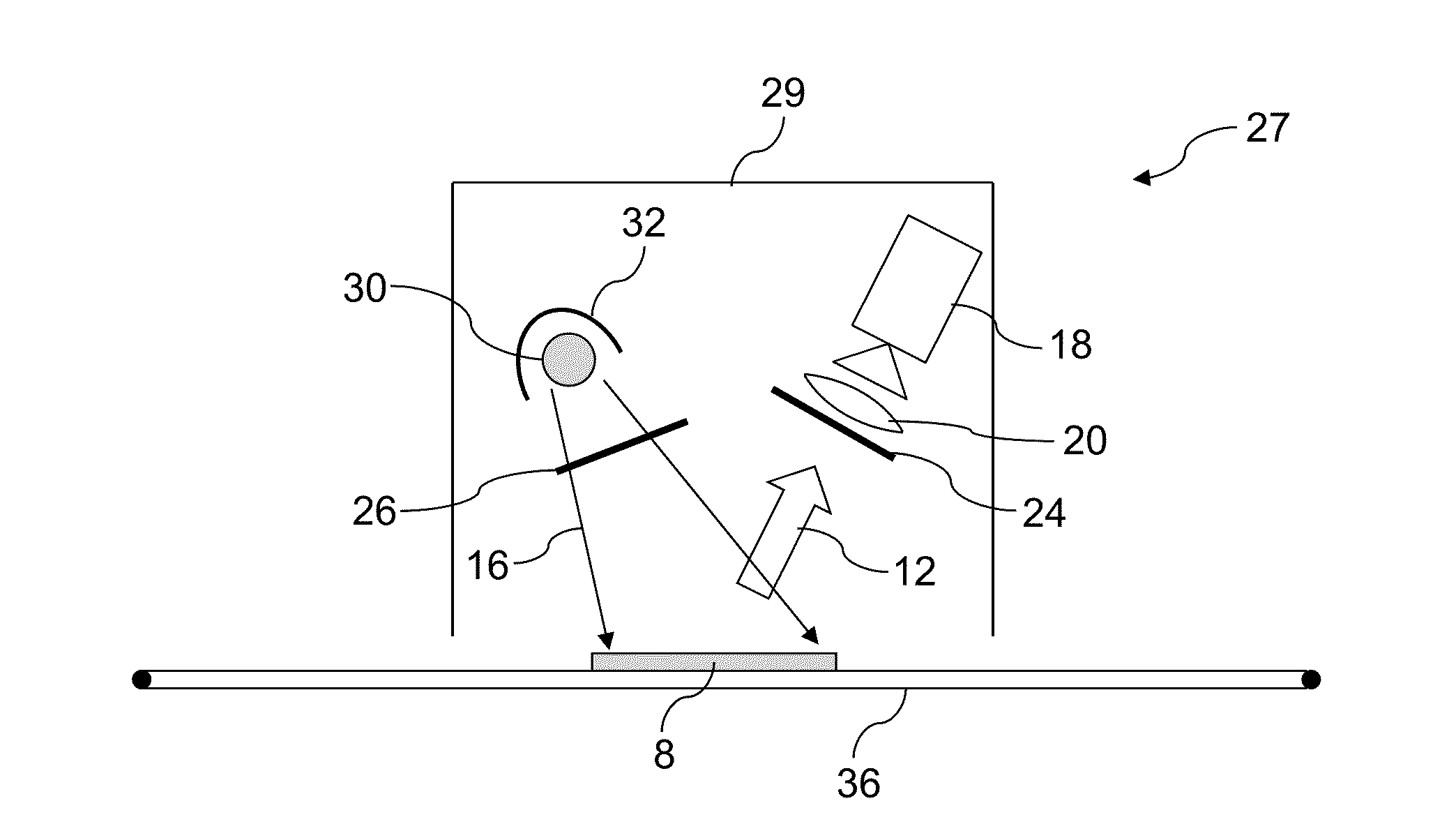

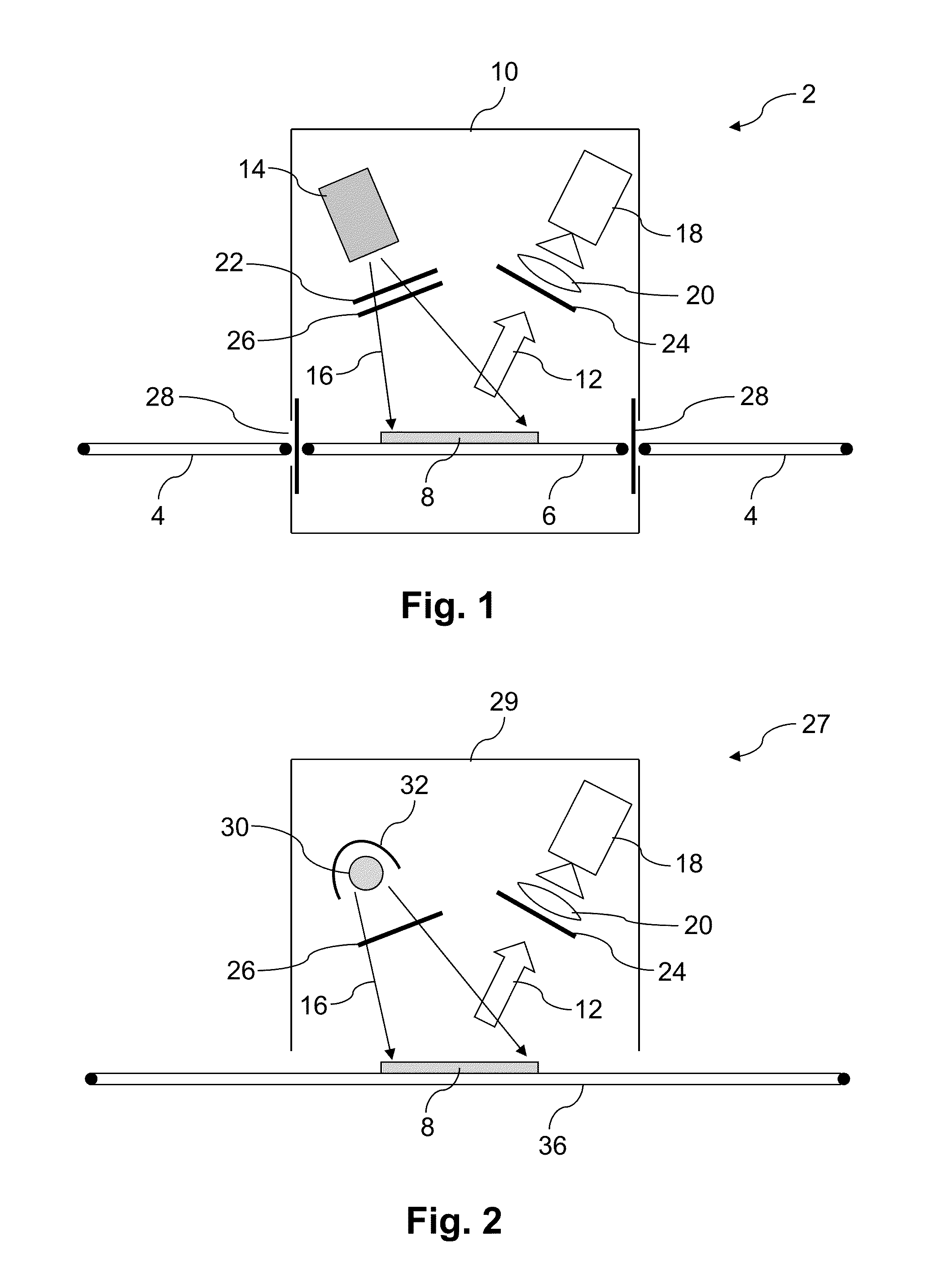

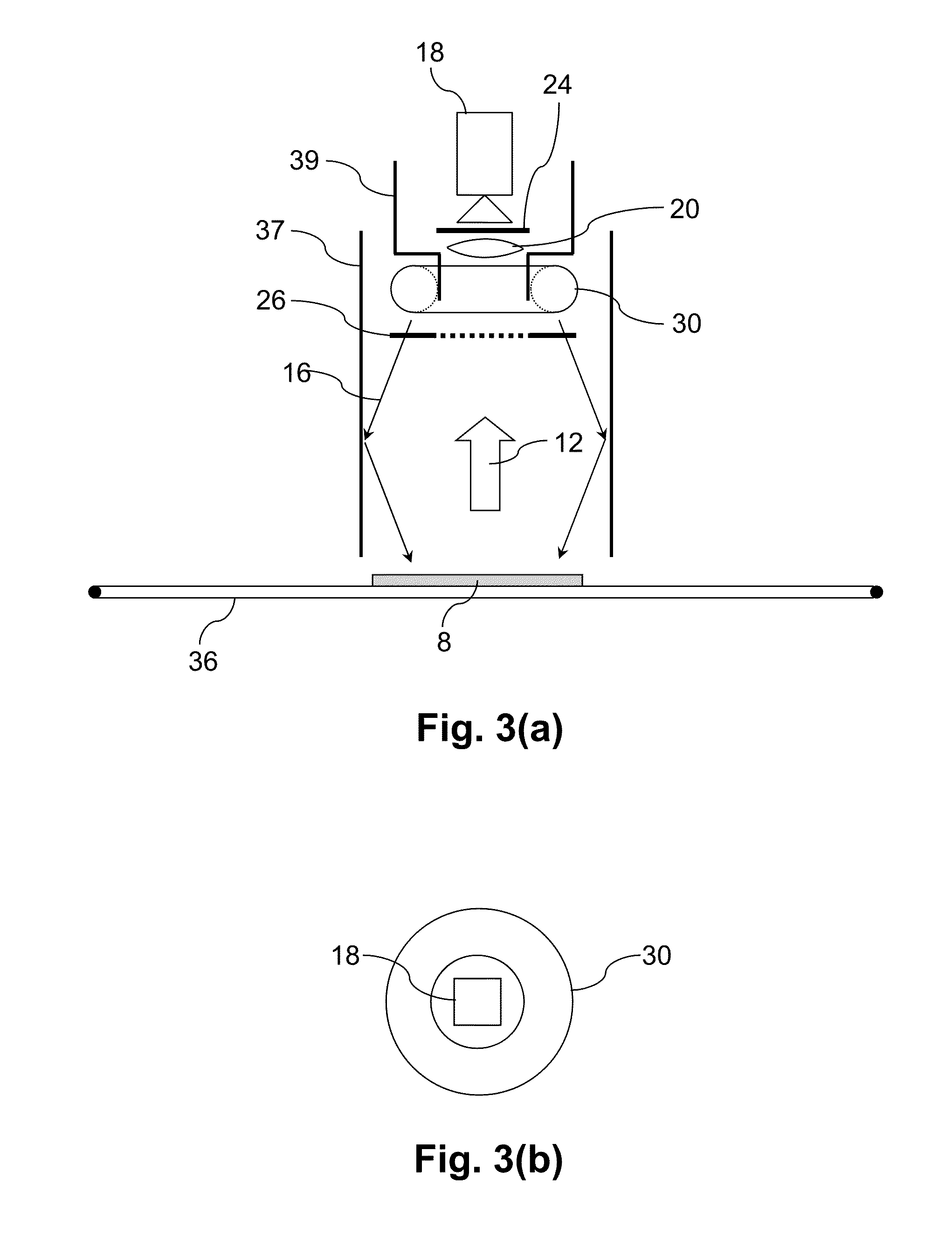

[0060]FIG. 1 shows a PL imaging system 2 suitable for acquiring PL images of semiconductor devices such as silicon PV cells during the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| capture time | aaaaa | aaaaa |

| capture time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com