Structure and process of heat dissipation substrate

a heat dissipation substrate and heat dissipation technology, applied in the field of metal substrates, can solve the problems of easy bend and deformation of the heat dissipation substrate, inconvenient operation, and insufficient steps and fabrication costs, and achieve the effect of reducing fabrication steps and fabrication costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

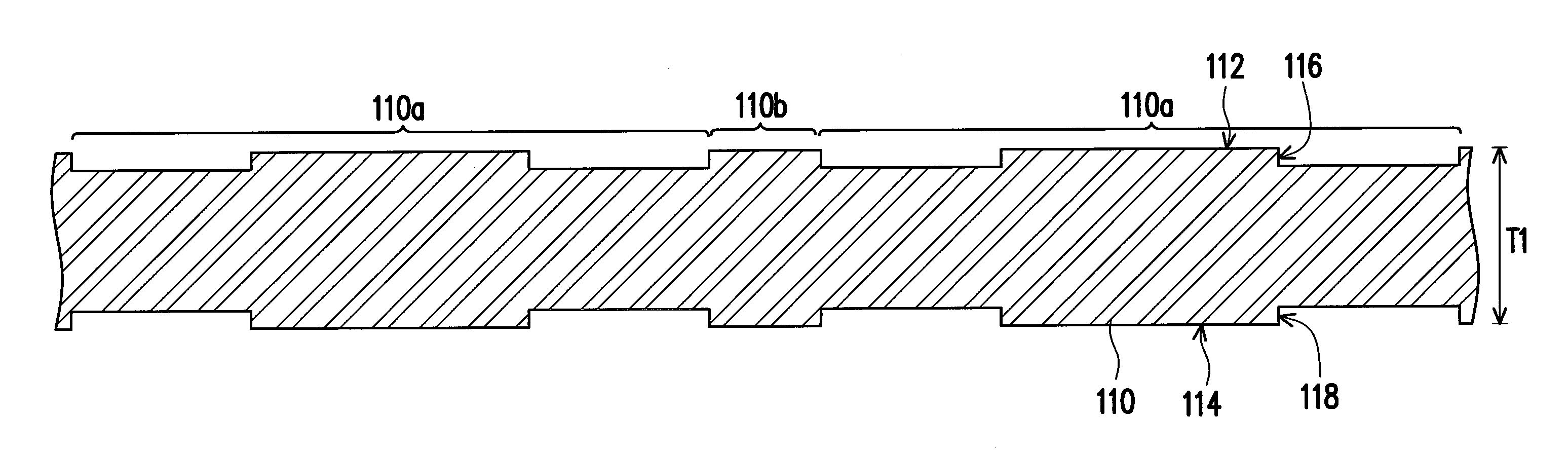

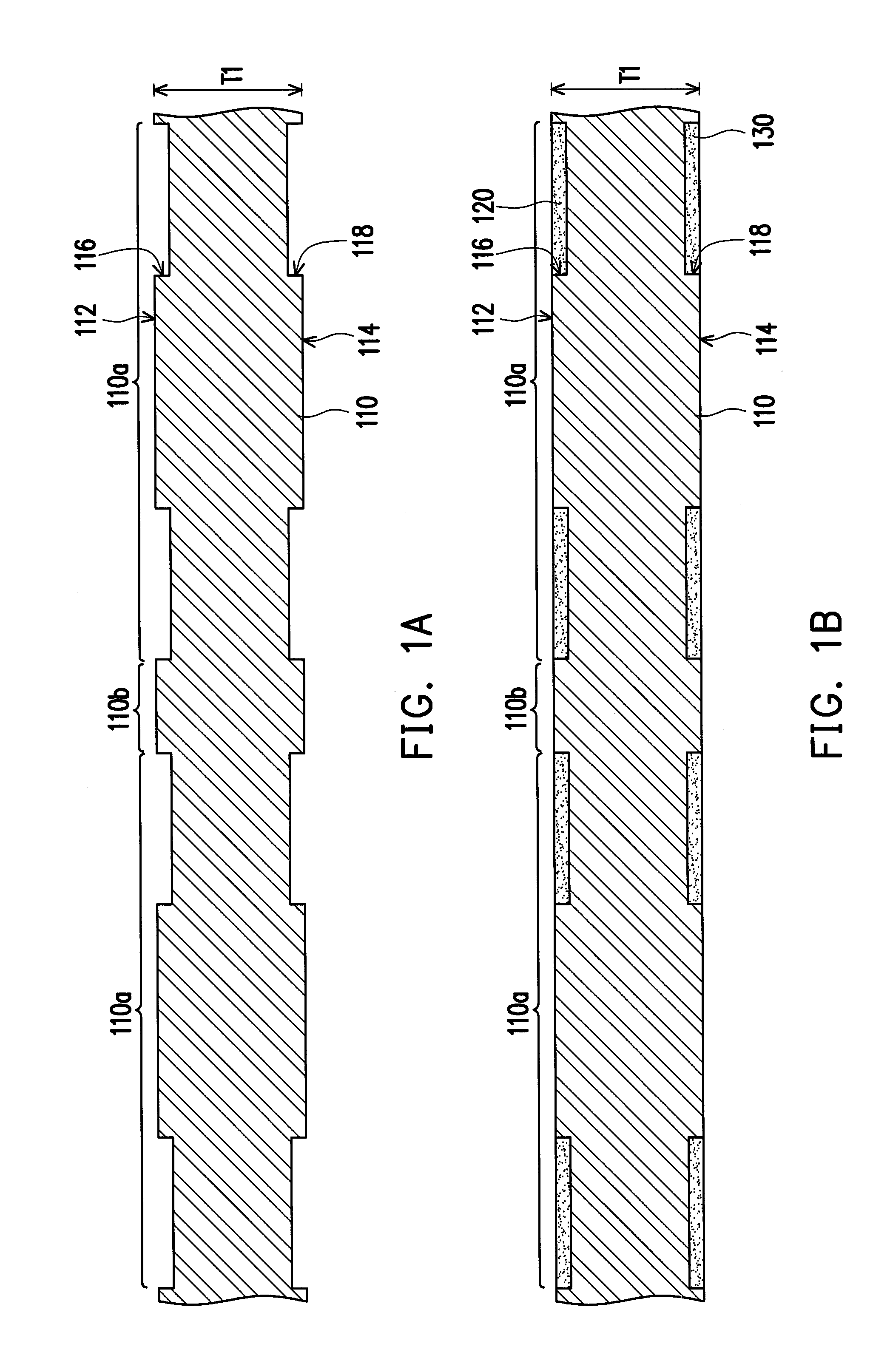

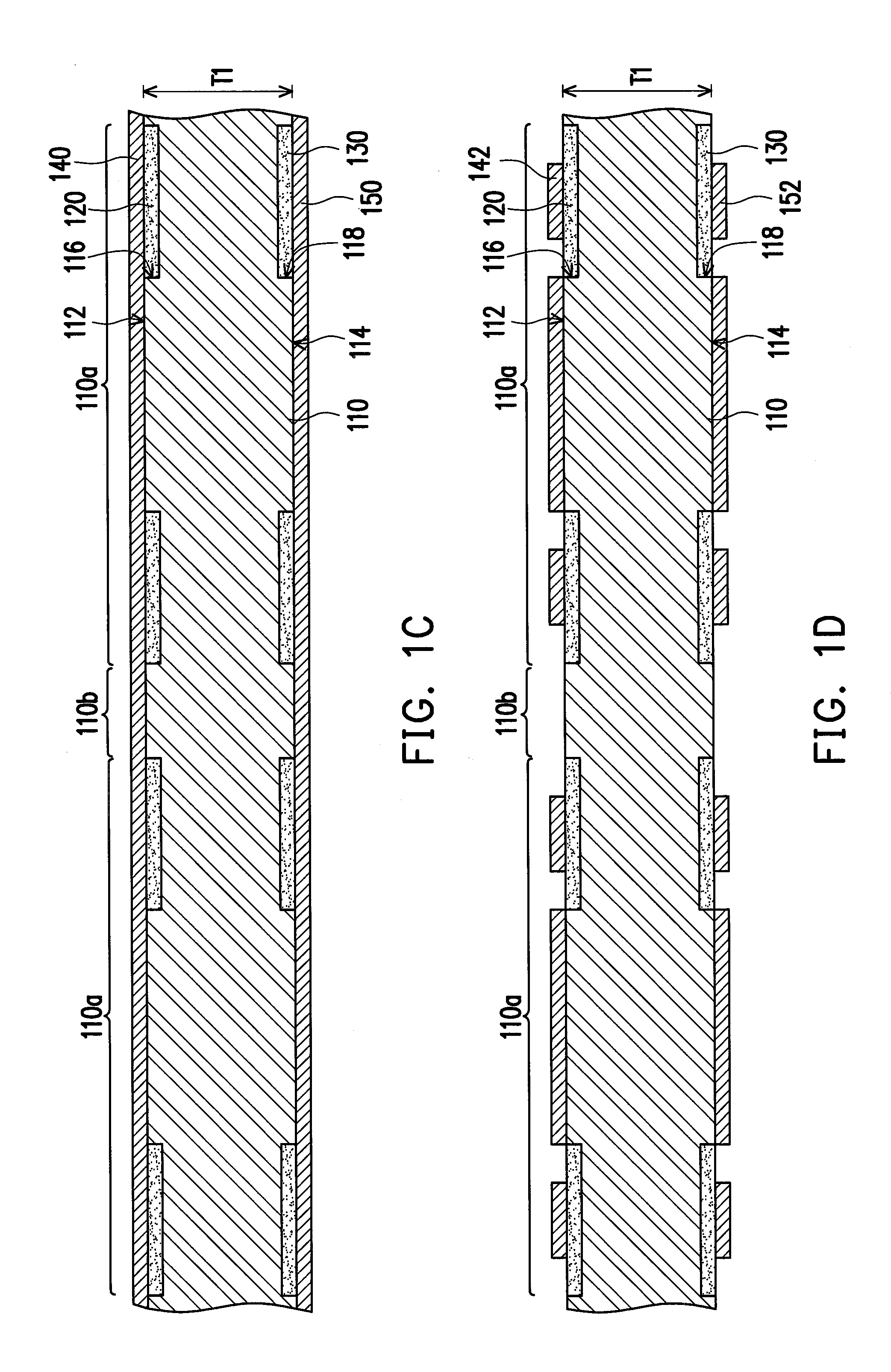

[0023]FIGS. 1A to 1E are schematic cross-sectional views illustrating a flowchart of a fabrication process of a heat dissipation substrate in one embodiment of the invention. FIG. 1F is a schematic cross-sectional view of a heating device loaded on a heat dissipation substrate in FIG. 1E. Referring to FIG. 1A, according to a method of fabricating a heat dissipation substrate of the present embodiment, a metal substrate 110 is first provided. The metal substrate 110 has an upper surface 112 and a lower surface 114 opposite to each other. The metal substrate 110 has a thickness T1 less than 0.6 millimeter (mm) and is fabricated with copper, for example.

[0024]Referring to FIG. 1A, a plurality of first recesses 116 is formed on the upper surface 112 of the metal substrate 110 and a plurality of second recesses 118 is formed on the lower surface 114 of the metal substrate 110. Here, positions of the first recesses 116 correspond to positions of the second recesses 118 respectively. In th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com