Method for producing foamed slag on high-chromium melts in an electric furnace

a technology of high-chromium steel melts and foamed slag, which is applied in the direction of electric furnaces, furnaces, metal processing, etc., can solve the problems of time delay in reaction and foaming reaction, and achieve the effect of reducing the chromium increasing and reducing the chromium oxide content of the slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

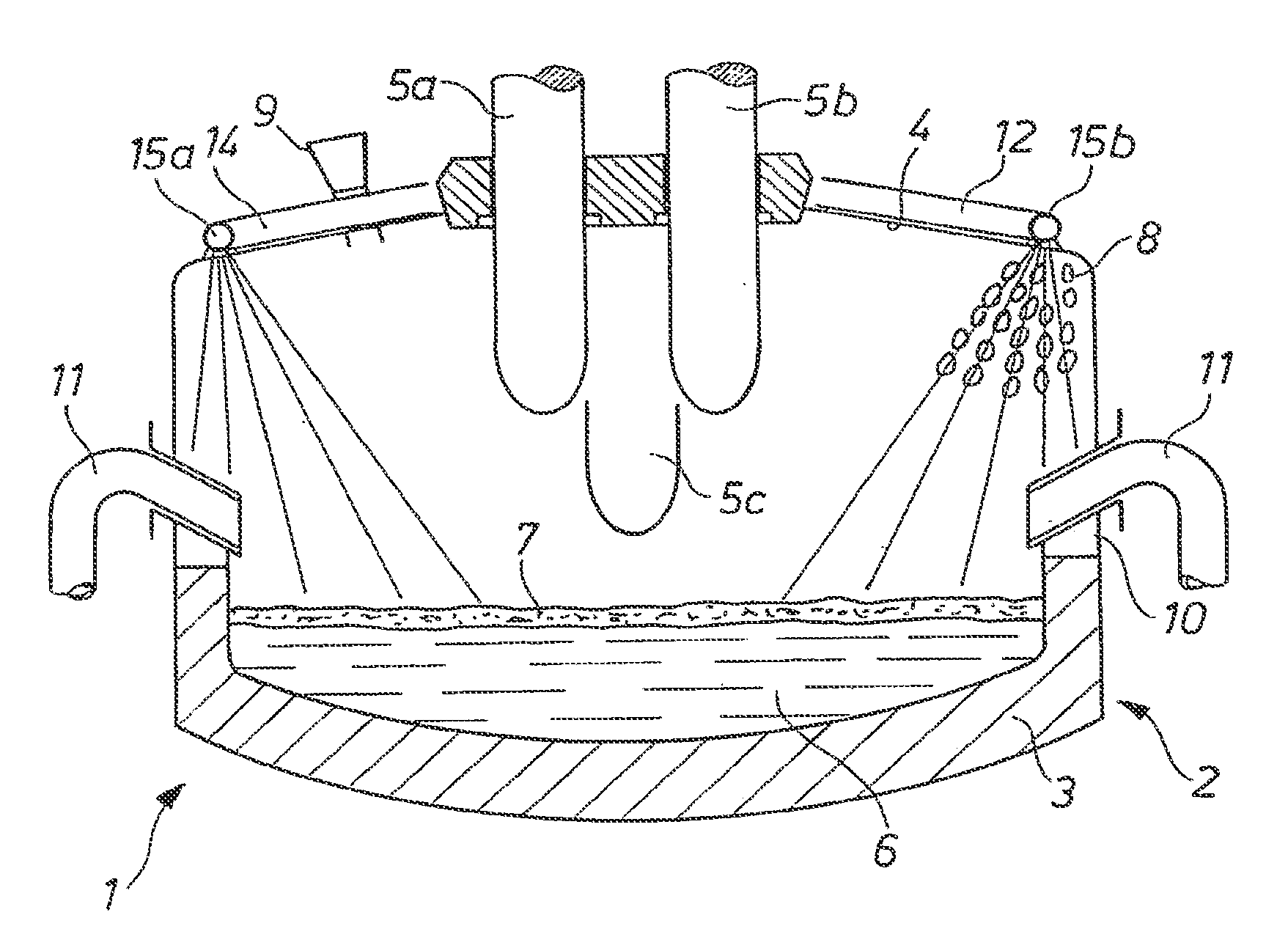

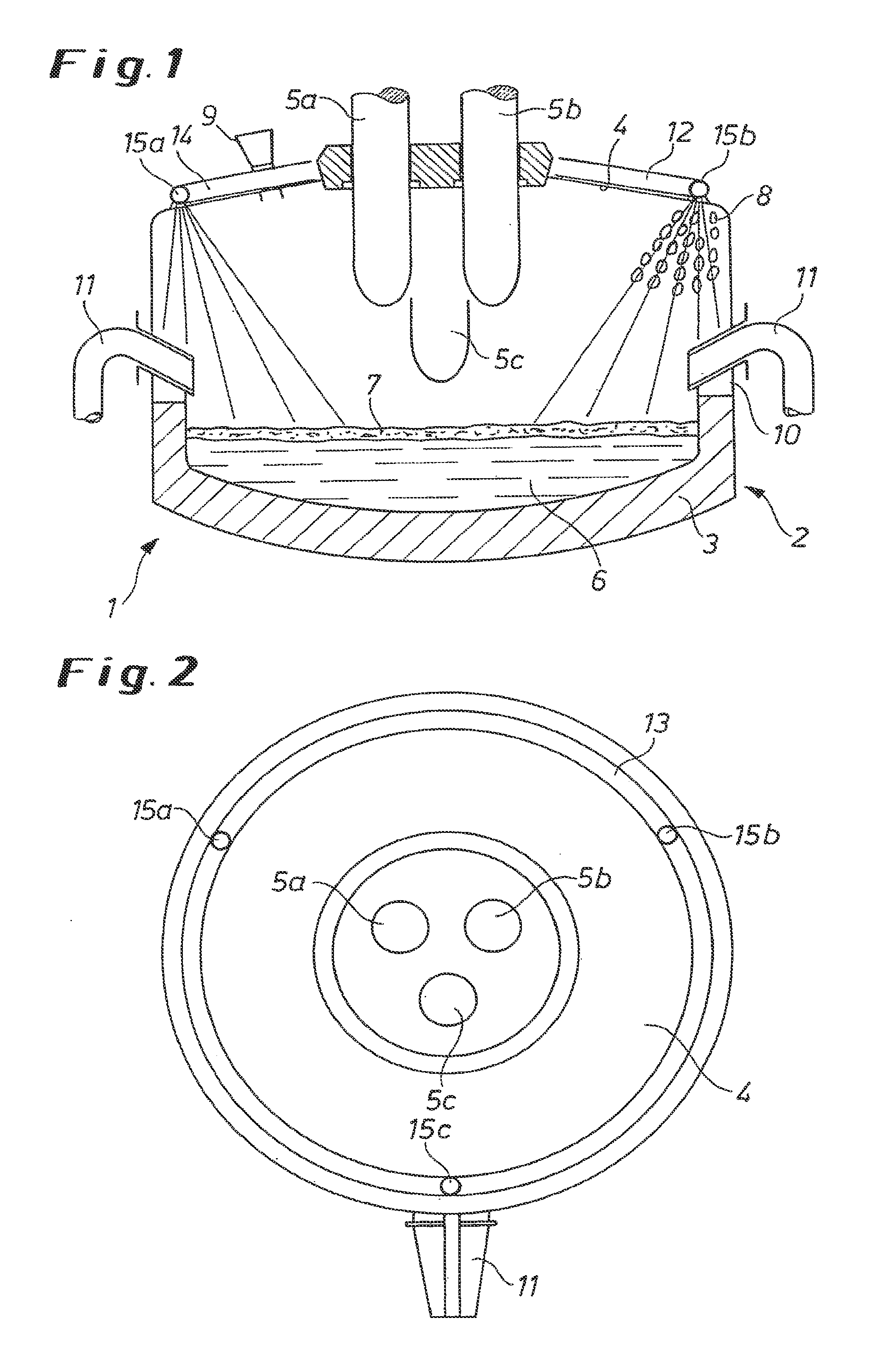

[0024]The electric arc furnace 1 shown in FIG. 1 comprises a furnace shell 2 with a refractory wall 3 and a furnace roof 4. After the furnace has been charged with scrap and alloying components, three electrodes (in the present case) 5a-c are lowered into the interior of the furnace. The solid material is melted down by the electric arcs that are produced. A slag layer 7 is formed and floats on the melt. To initiate a foaming reaction of the slag 7 between the electrodes 5a-c and the refractory furnace wall 3, slag-foaming material is introduced into the interior of the furnace as preforms 8, namely, in the form of pellets. The pellets are preferably charged through the furnace roof 4, specifically, through the fifth roof hole 9, and / or the sidewalls 10. Injection systems with injection lines or gravity feed systems 11 that extend through the sidewalls 10 of the furnace are provided for this purpose. Instead of injection lines, it is also possible to use injection lances.

[0025]Alter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com