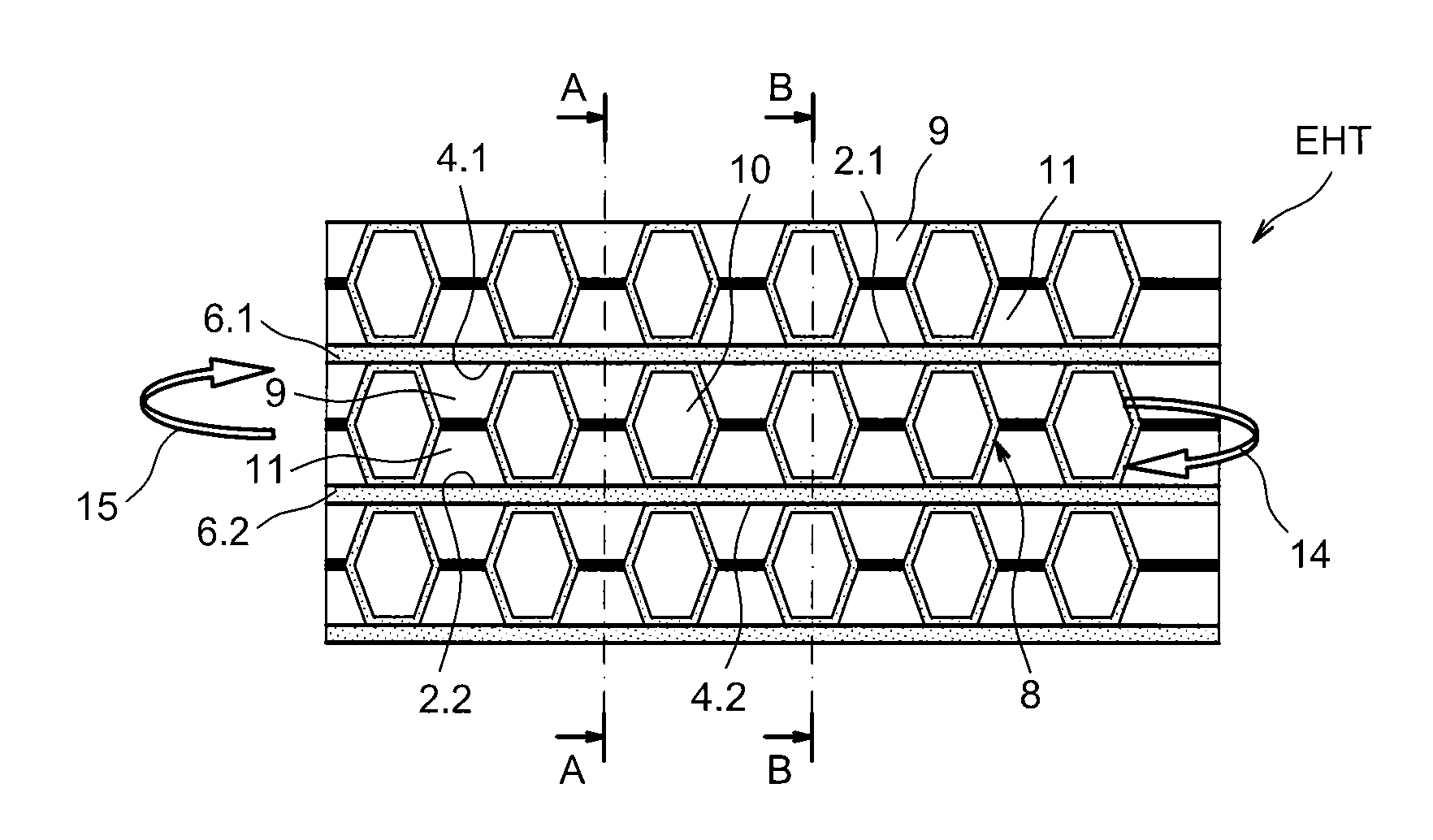

Electrochemistry method having improved efficiency and associated electrochemical reactor such as a high temperature electrolyser (EHT)

a high temperature electrolyser and electrochemical technology, applied in the field of electrochemistry methods, can solve the problems of reducing the average production, reducing the efficiency of steam consumption, and high hydrogen conversion rate,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

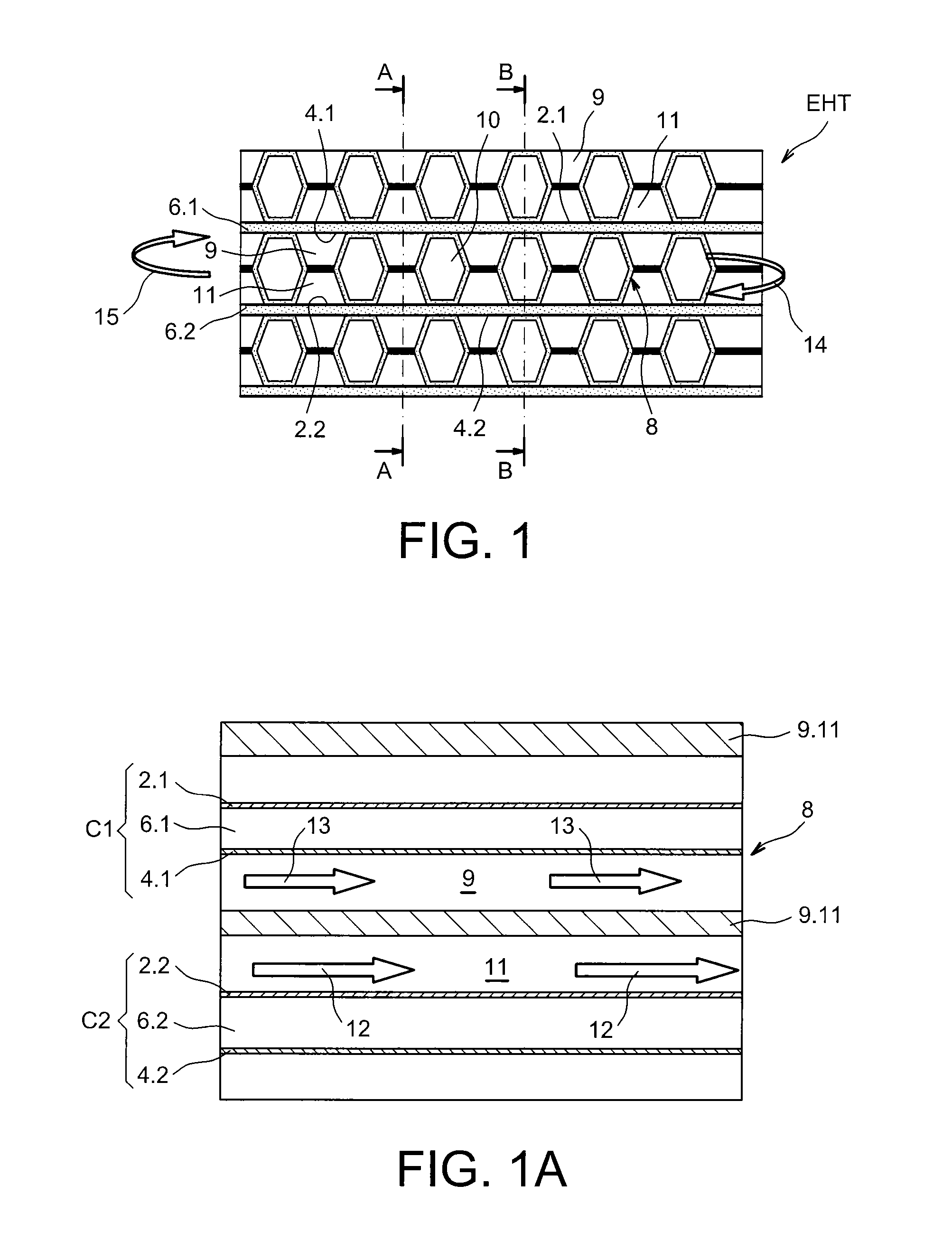

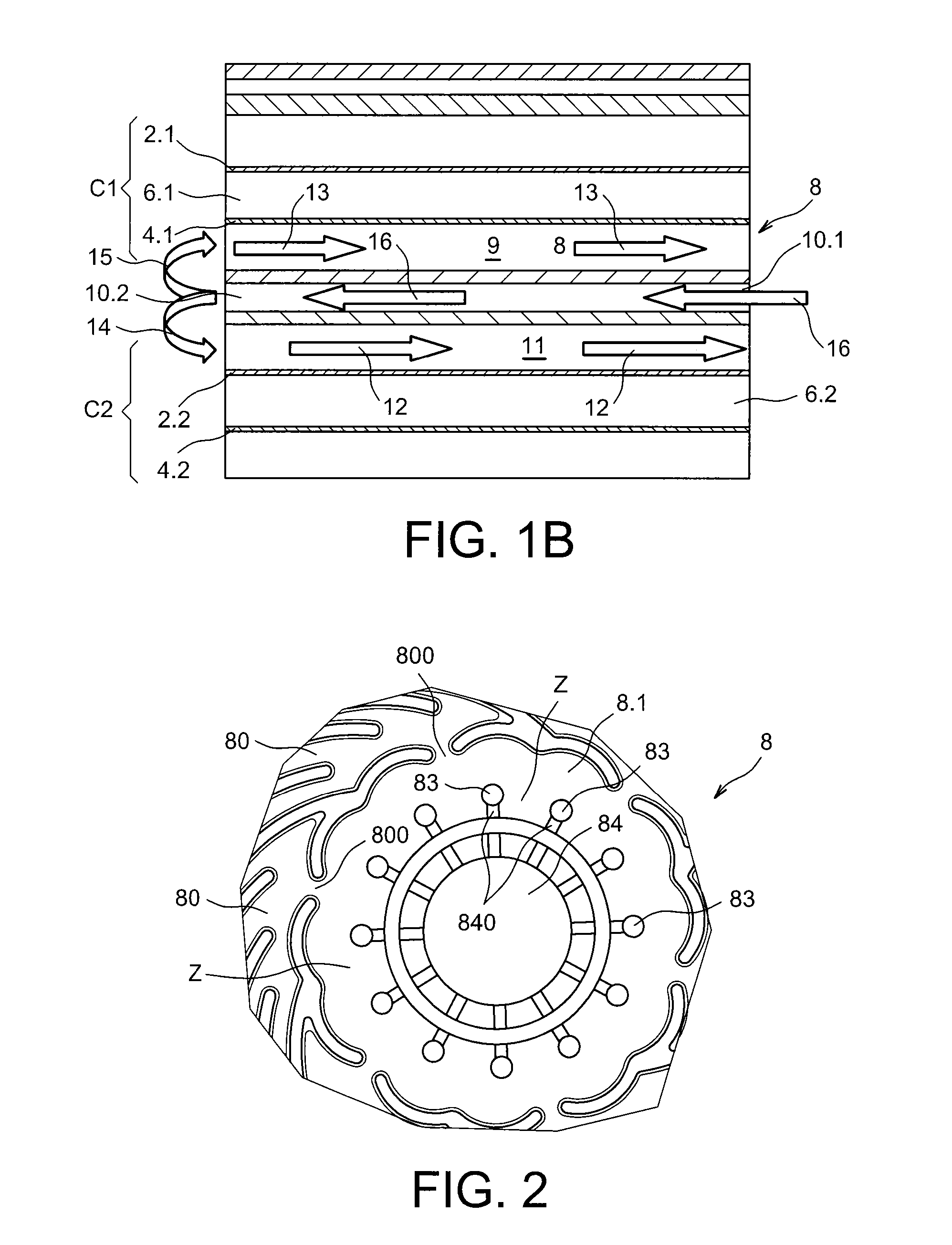

[0015]To accomplish this, one aim of the invention is an electrochemistry method to produce a reaction gas of lesser molar mass than that of the initial constituent(s) in the form of gas or vapour, according to which the gas or vapour of the initial constituent(s) is / are made to flow, and the reaction gas is recovered in the path in which the initial constituent(s) is / are made to flow, characterised in that at least one vortex is created in a zone upstream from the reaction gas recovery zone, where the vortex is able to separate the produced reaction gas from the initial constituent(s) which is / are still present, in order to subject the latter to an electrochemical process in the said upstream zone.

[0016]It is self-evident that a zone upstream from the reaction gas recovery zone must be considered in the broad sense as being a reaction zone in which the transformation from steam to hydrogen takes place.

[0017]Thus, the invention essentially consists in slowing the output of the initi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| tangential speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com