Working apparatus, in particular excavator or machine for material handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

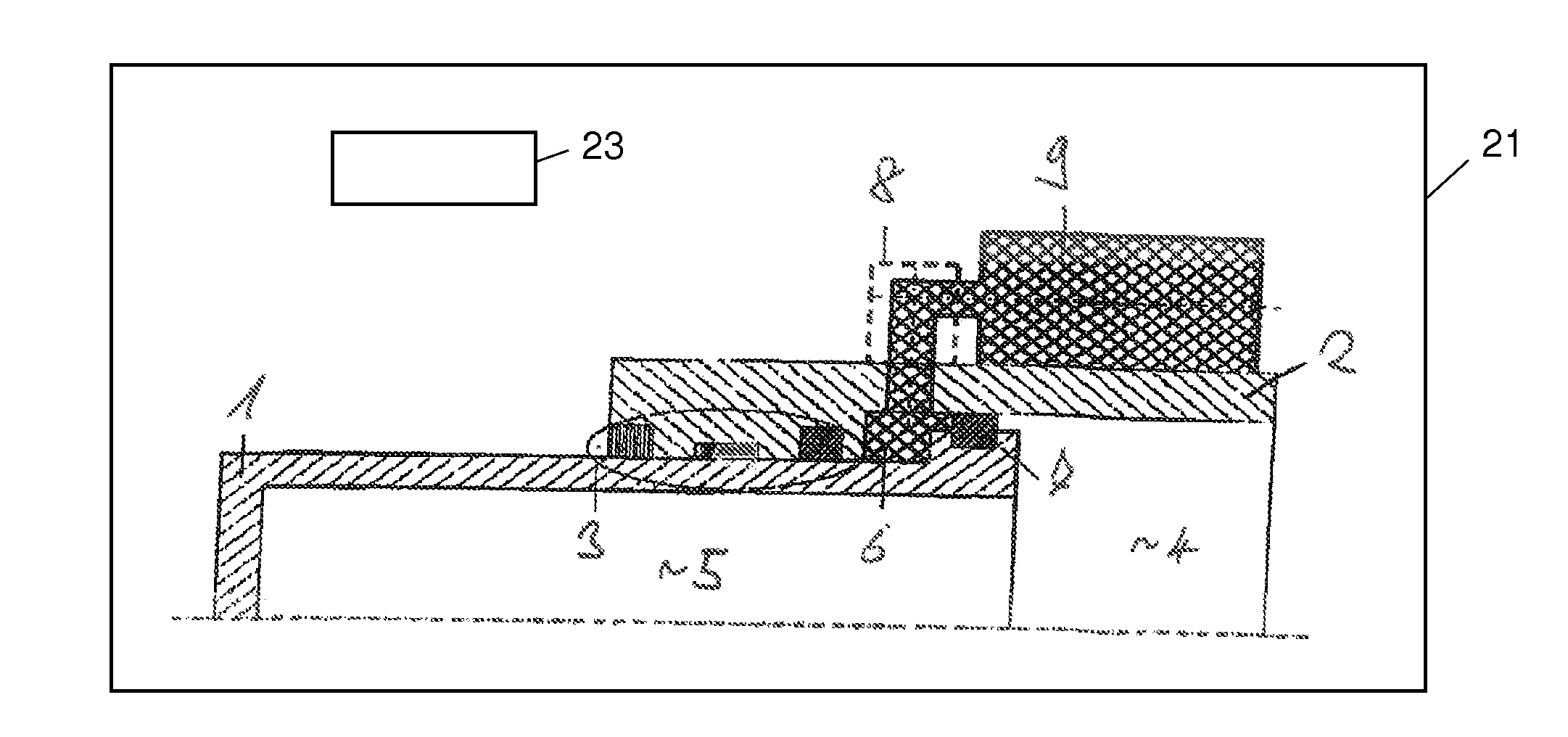

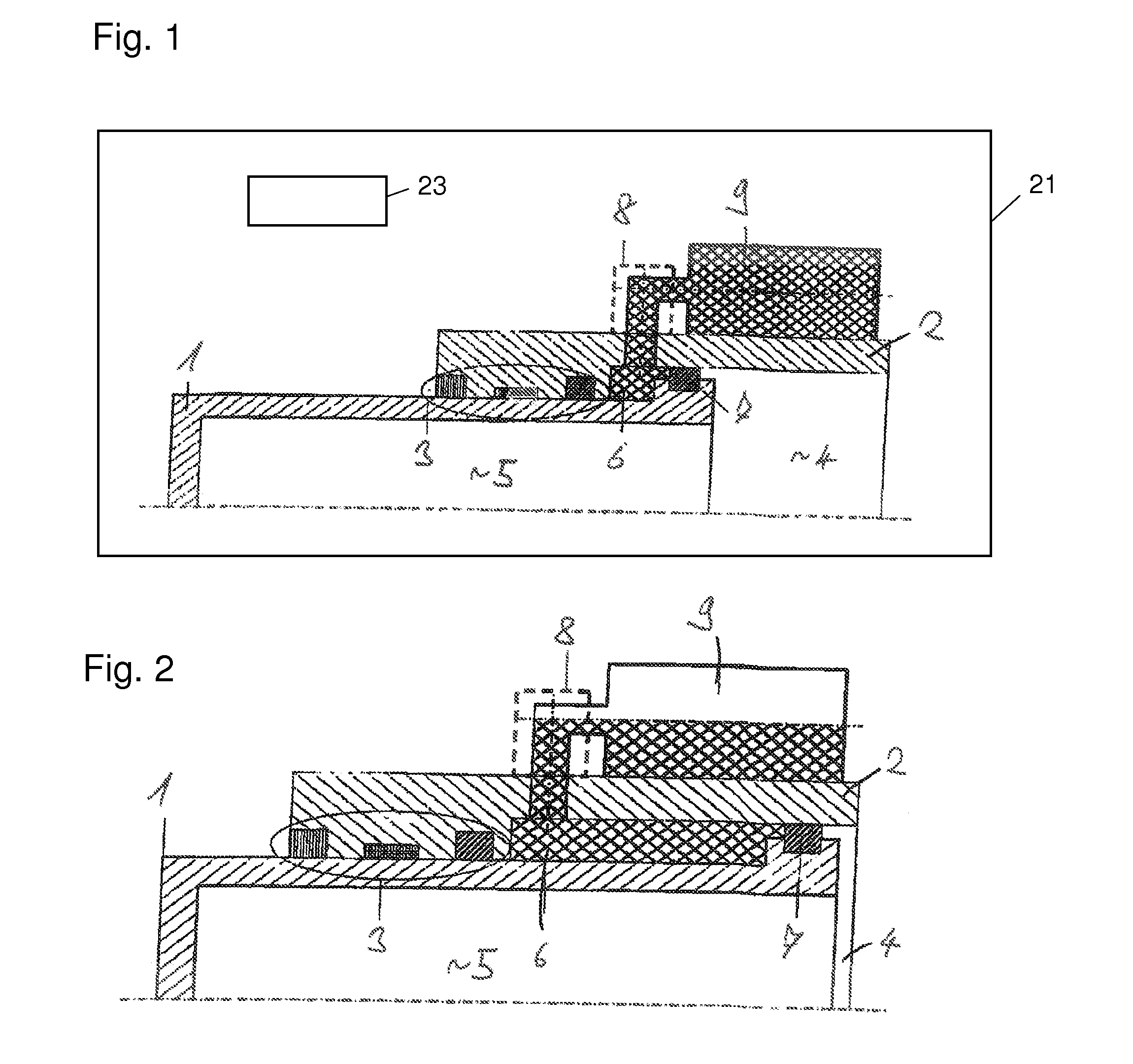

[0030]In the present disclosure shown in FIGS. 1 and 2, the annular space 6 is filled with a non-compressible medium, for example hydraulic oil. In this respect, the annular space 6 is in communication with an external container 9 via a flow restriction element 8. If the pressurized energy recovery cylinder can expand in an uncontrolled manner, e.g. due to a defect in the bearing points, the medium located in the annular space 6 has to flow through the flow restriction element into the external container 9. It is hereby no longer possible for the cylinder to expand in an uncontrolled manner.

[0031]The flow restriction element advantageously has a restrictor, a diaphragm or a valve unit. In this respect, the flow speed can advantageously be set by the flow restriction element. The valve unit can in this respect in particular be a flow control valve or a burst pipe protection.

[0032]FIG. 1 in this respect shows the energy recovery cylinder in accordance with the present disclosure with ...

second embodiment

[0033]In the second embodiment shown in FIG. 3, the annular space 6 is, in contrast, filled with gas and is in communication with the base side 4 via the flow restriction element 10. The gas is hereby restricted on the overflow between the annular space 6 and the base side 4 so that an uncontrolled moving out of the piston rod 1 is likewise prevented. In this respect, a restrictor 10 is advantageously used as the flow restriction element. A check valve 11 is advantageously provided parallel hereto and allows a free flow of the gas from the base side 4 into the annular space 6.

[0034]The present disclosure thus ensures a controlled expansion or moving out of an energy recovery cylinder under high pressure when it is no longer mechanically secured due to a defect of a bearing part.

[0035]While only FIG. 1 shows the working apparatus 21 and working cylinder 23, such components may also be included in FIGS. 2 and 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com