Heating apparatus, transportation unit, system and method for removing foodstuffs

a technology of transportation unit and foodtuff, which is applied in the direction of power operated devices, containers, opening closed containers, etc., can solve the problems of insufficient heat, cumbersome transportation of large quantities of highly viscous or solid foodstuffs at ambient temperatures, and insufficient heat transfer of glucose syrup from one unit to another unit at these temperatures, etc., to achieve easy heating, high viscosity or solid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]The following is a description of various embodiments of the invention, given by way of example only and with reference to the drawings.

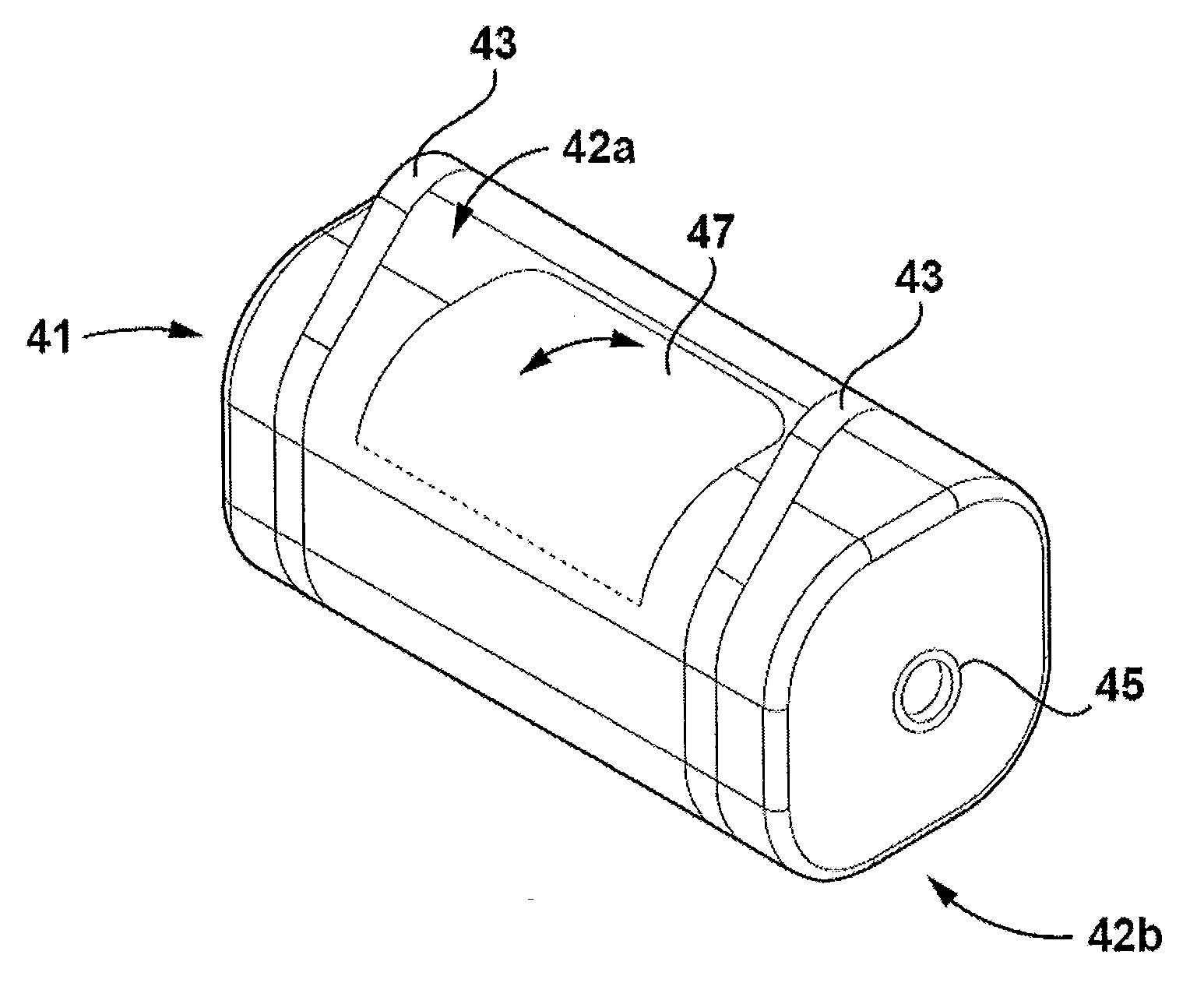

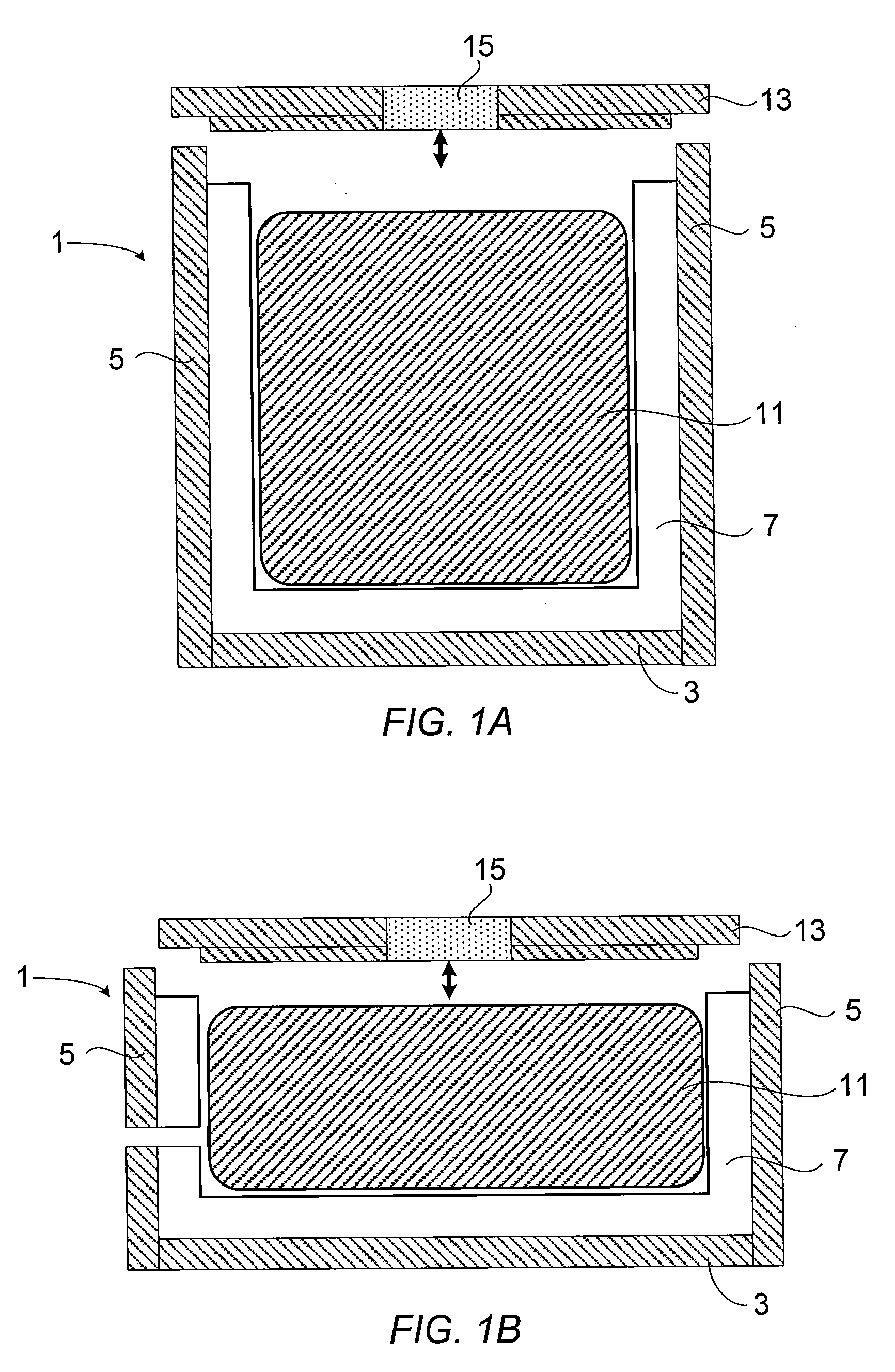

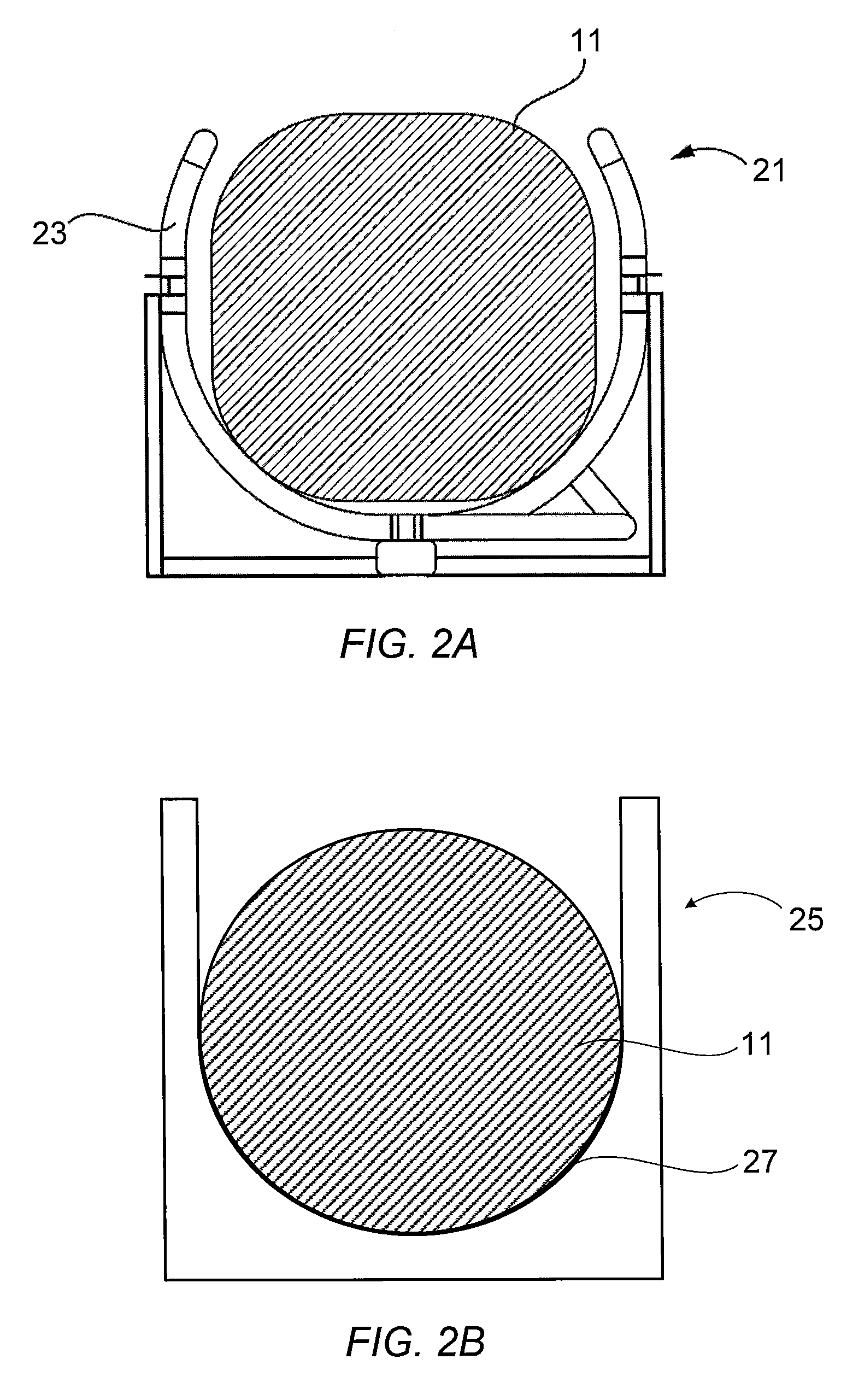

[0034]FIGS. 1A, 1B schematically show a cross-section of an embodiment of an apparatus 1 for heating foodstuffs that are highly viscous or solid at ambient temperatures according to an embodiment of the invention. FIG. 1A is a cross-section along the width of the heating apparatus 1, while FIG. 1B shows a cross-section taken along the length of the heating apparatus 1.

[0035]The apparatus 1 comprises a housing having a bottom 3 and side walls 5, and a heating system within the housing. The housing is arranged to accommodate a transportation unit 11 filled with foodstuffs that are highly viscous or solid at ambient temperatures. The housing may further comprise an outlet opening 7 for facilitating removal of foodstuffs from the heating apparatus 1. The heating apparatus 1 may be moveable in its entirety, which enables flexible use of the apparat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com