Weather strip and production method thereof

a weather strip and production method technology, applied in the field of weather strips, can solve the problems of reducing the productivity or increasing the cost, reducing the width dimension, and increasing the load in the vicinity of the connecting portion, so as to prevent the deterioration of the sealing capability, reduce the quality of the appearance of the weather strip or the sealing capability, and improve the appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

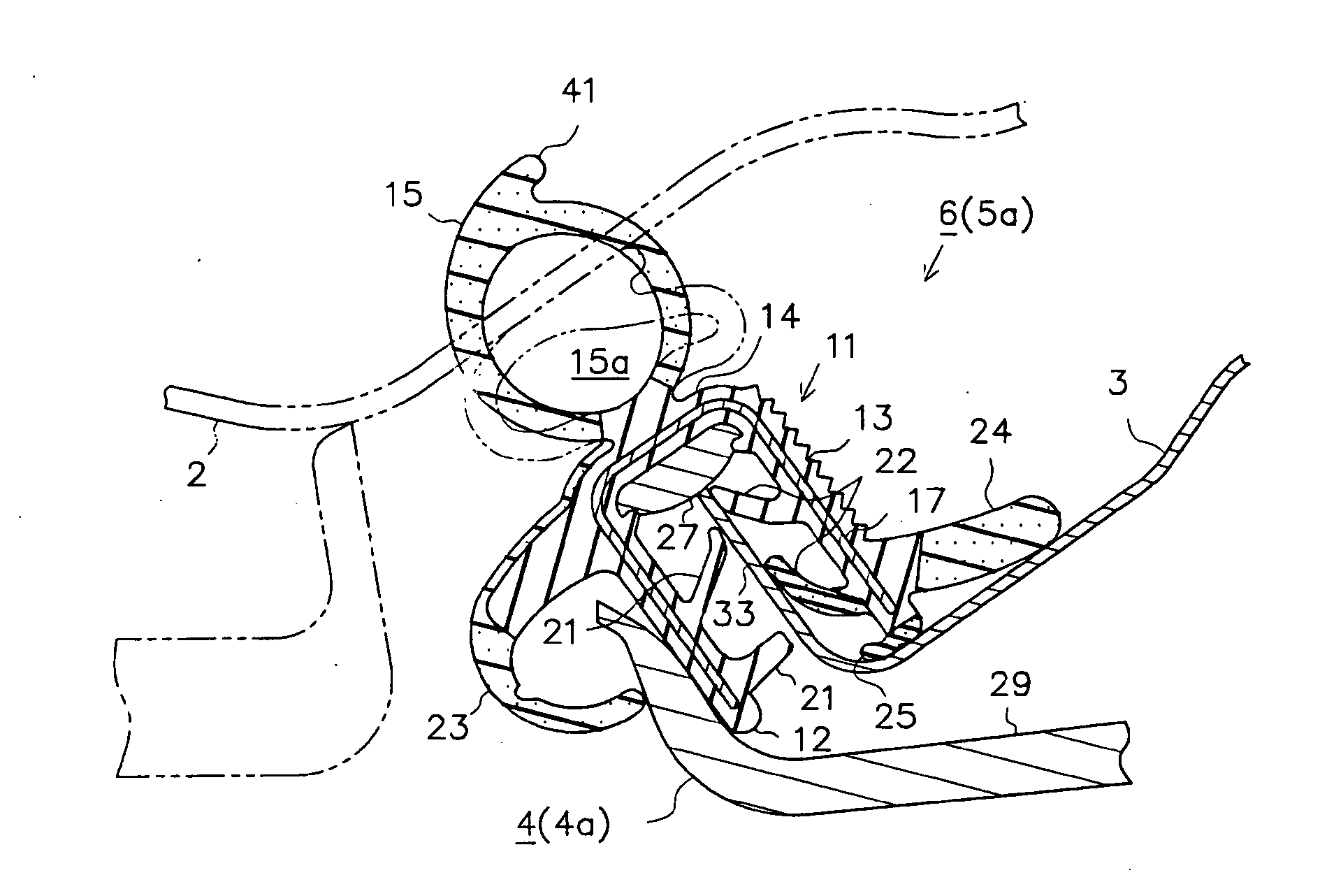

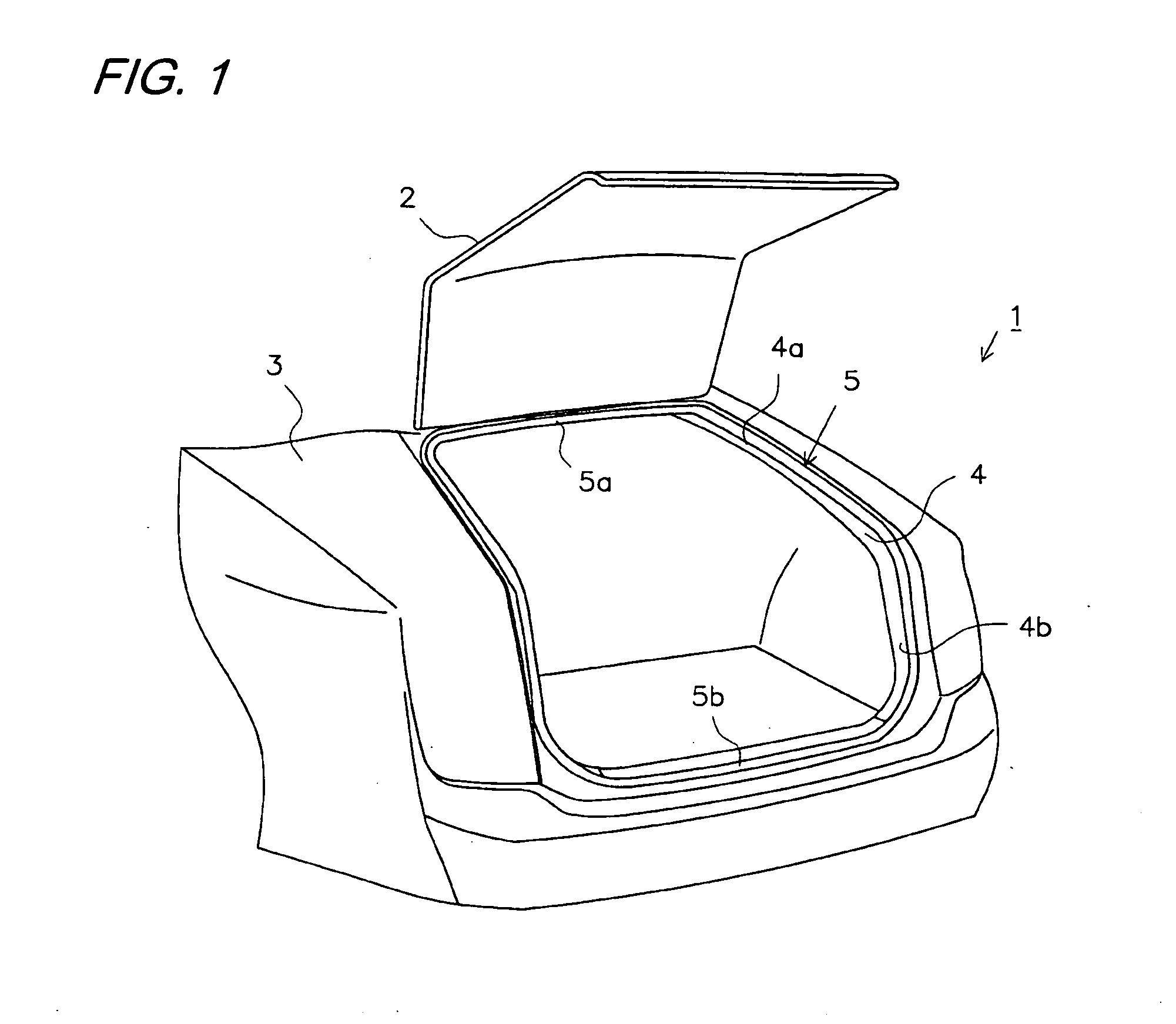

[0102]A first embodiment will now be described with reference to the accompanying drawings. As shown in FIG. 1, an automobile 1 serving as an automobile vehicle is provided with a luggage compartment door 2 serving as an opening / closing member for opening and closing an opening 4 of a luggage compartment which is formed in a body 3 serving as an automobile body. In addition, a circumferential edge of the opening 4 is provided with a weather strip 5 for sealing a gap between the luggage compartment door 2 and a circumferential edge of the opening 4 when the luggage compartment door 2 is closed.

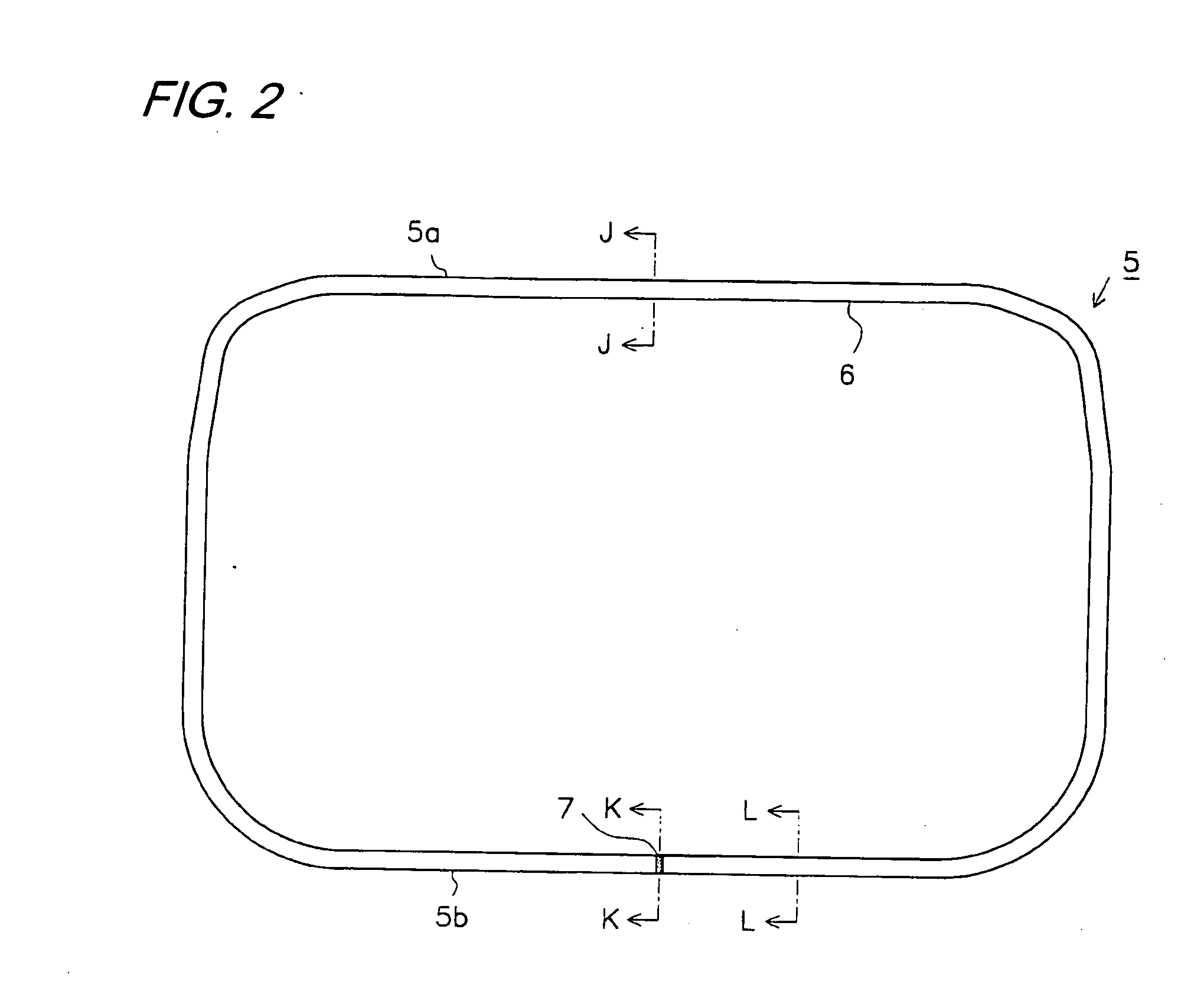

[0103]As shown in FIG. 2, the weather strip 5 according to the first embodiment includes an extrusion molded portion 6 formed in the shape of a substantially straight line by injection molding, and an injection molded portion 7 (portion indicated by a scatter plot shape in FIGS. 2 and 5) for connecting both ends of the extrusion molded portions 6 in the shape of a straight line, and is formed i...

second embodiment

[0152]A second embodiment will now be described with reference to the accompanying drawings. FIG. 12 is a perspective view illustrating an automobile in a state in which a front door is opened. FIG. 13 is a front view of a weather strip. FIG. 14 is a cross-sectional view taken along the line J-J in FIG. 13 illustrating a weather strip.

[0153]As shown in FIG. 12, an automobile 101 serving as an automobile vehicle is provided with an automobile door (front door in the drawing; referred to as a “door 102”) which can be opened or closed. In addition, a circumferential edge of a door opening 4 of an automobile body 103 (automobile body) corresponding to the door 102 is provided with an opening trim weather strip 105 (referred to as a “weather strip 105”).

[0154]As shown in FIG. 13, the weather strip 105 according to the second embodiment includes an extrusion molded portion 106 formed in the shape of a substantially straight line by injection molding, and an injection molded portion 107 (p...

third embodiment

[0208]A third embodiment will now be described with reference to the accompanying drawings. FIG. 22 is a perspective view illustrating a loop panel or the like of an automobile. FIG. 23 is a front view of a weather strip. FIG. 24 is a cross-sectional view taken along the line J-J in FIG. 23 illustrating a weather strip.

[0209]As shown in FIG. 22, a loop panel 201 of an automobile vehicle is provided with a loop panel opening 202 and a sliding loop 203 serving as a movable loop for opening and closing the loop panel opening 202. A circumferential edge of the sliding loop 203 is provided with a sliding loop weather strip 205 (referred to as a “weather strip 205”).

[0210]As shown in FIG. 23, the weather strip 205 according to the third embodiment includes an extrusion molded portion 206 formed in the shape of a substantially straight line by injection molding, and an injection molded portion 207 (portion indicated by a scatter plot shape in FIGS. 23 and 26) for connecting both ends of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| circumferential length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com