Muzzle loading rifle with centerfire cartridge ignition

a technology of centerfire and muzzle loader, which is applied in the field of muzzle loader, can solve the problems of difficult task and disadvantage of not being able to be used in what is normally thought of as a centerfire rifle, and achieve the effect of convenient handling and loading for operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

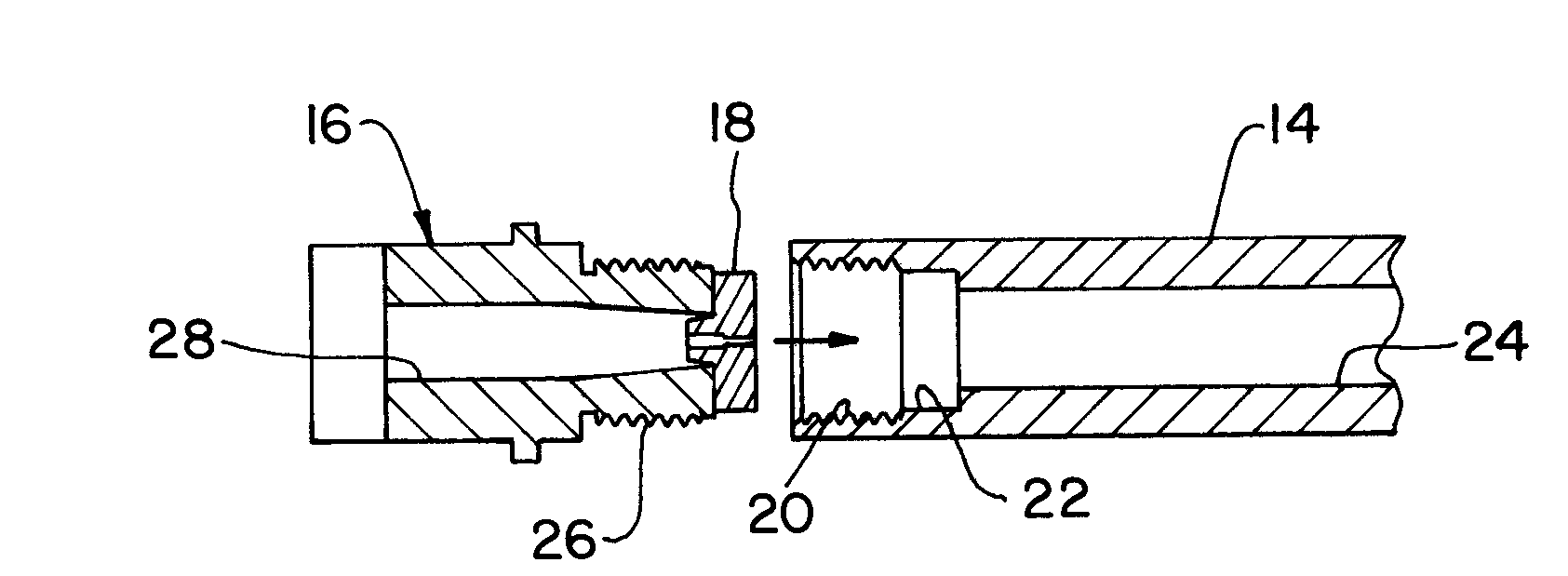

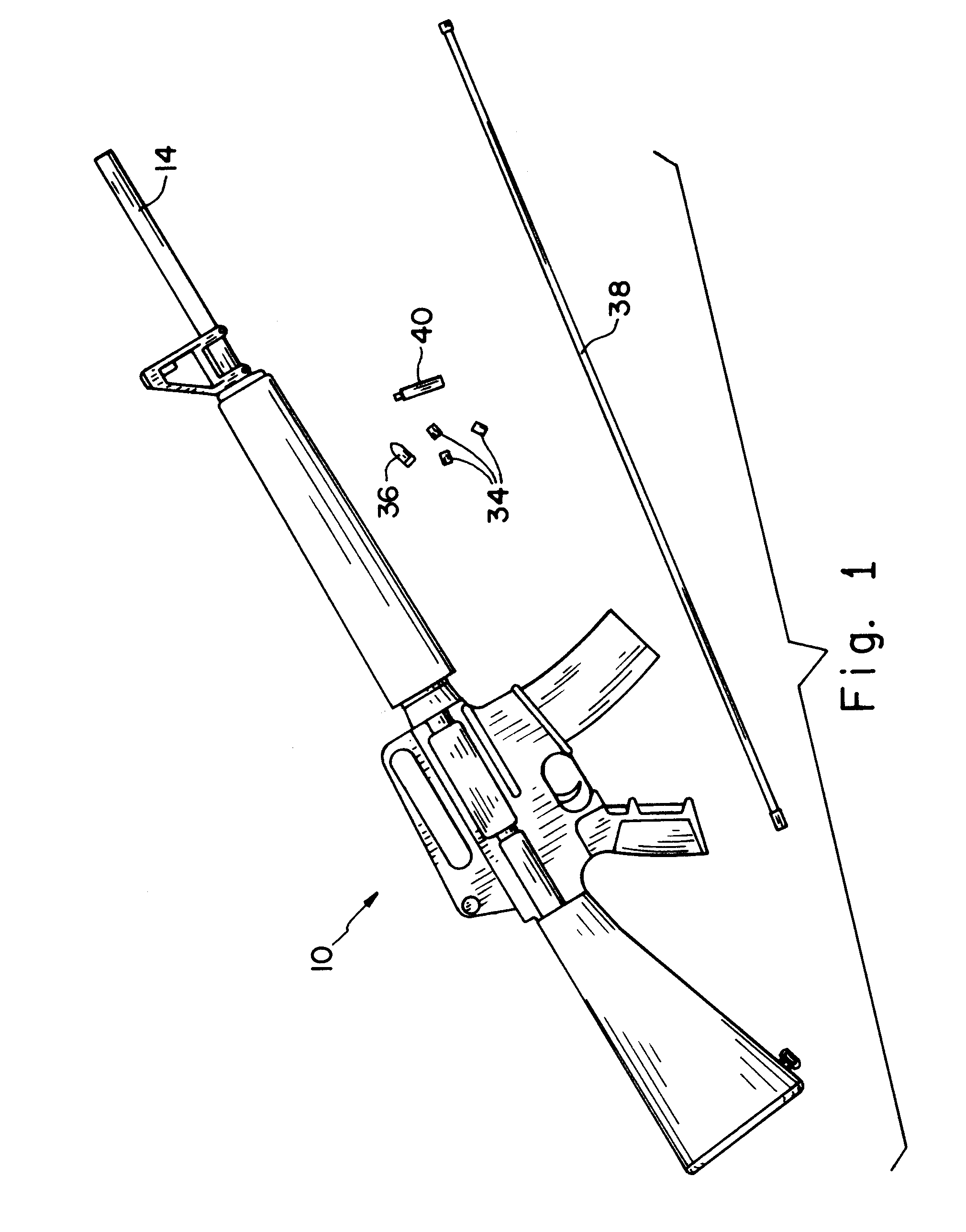

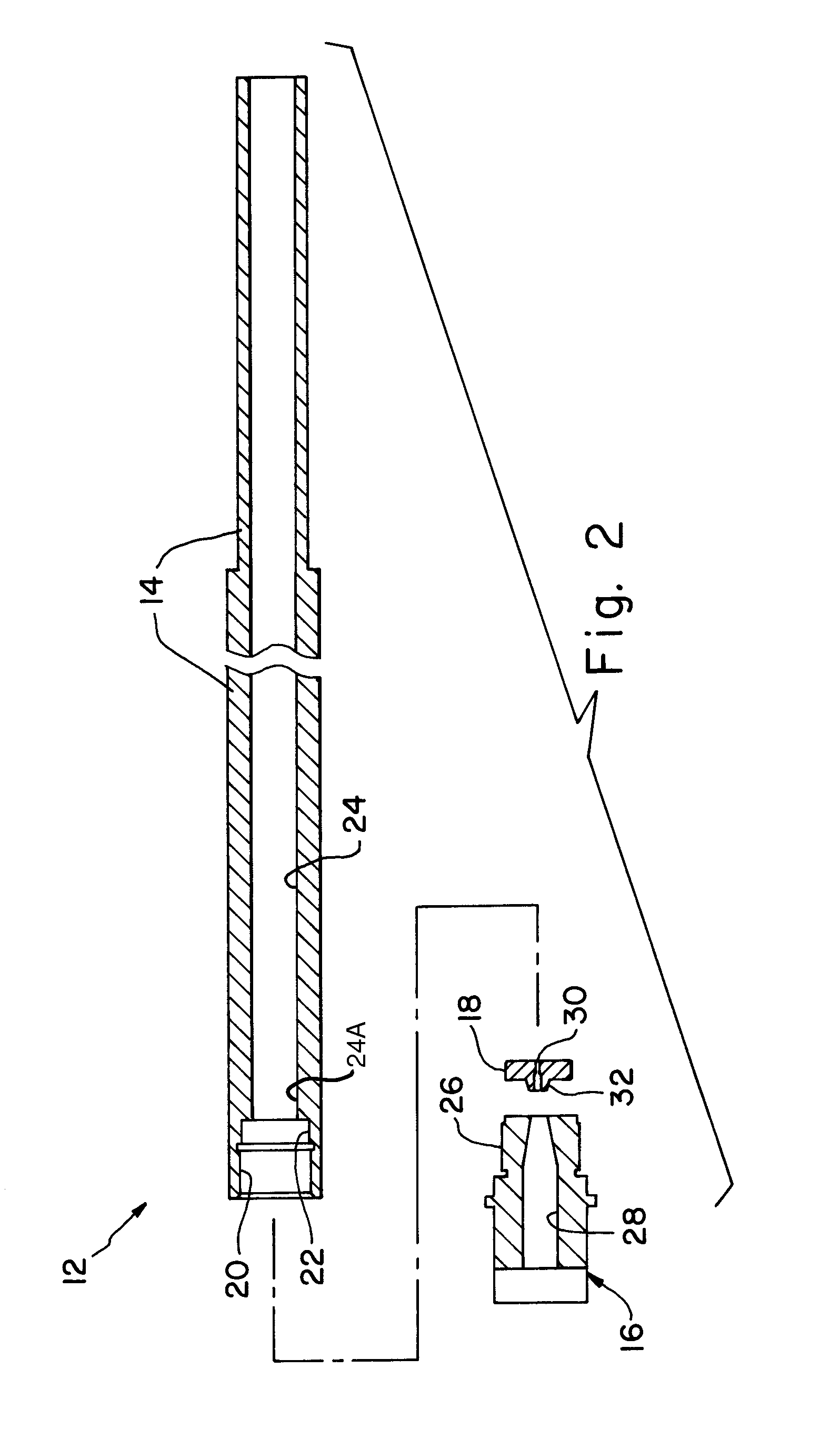

Referring now to the drawings, and more particularly to FIG. 1, there is shown an embodiment of a muzzle loading rifle 10 of the present invention. In the illustrated embodiment, muzzle loading rifle 10 is configured as an AR15 style rifle. The M16 / AR15 rifles are used worldwide by military and law enforcement organizations and civilian sport enthusiasts. M16 and AR-15 rifles are substantially the same, except that the M16 is switchable between automatic and semi-automatic operation, and the AR15 operates only in the semi-automatic mode. As a result, most of the components of M16 and AR15 rifles are substantially the same and are referred to as M16 / AR15 components.

An AR15 is generally constructed in modular “groups” allowing easy takedown and cleaning in the field. The upper receiver group generally includes the upper portion of the receiver, barrel, top rail and forestock. The lower receiver group includes the trigger assembly and pistol grip. The buttstock extends rearwardly from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com