Orthodontic appliance with encoded information formed in the base

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

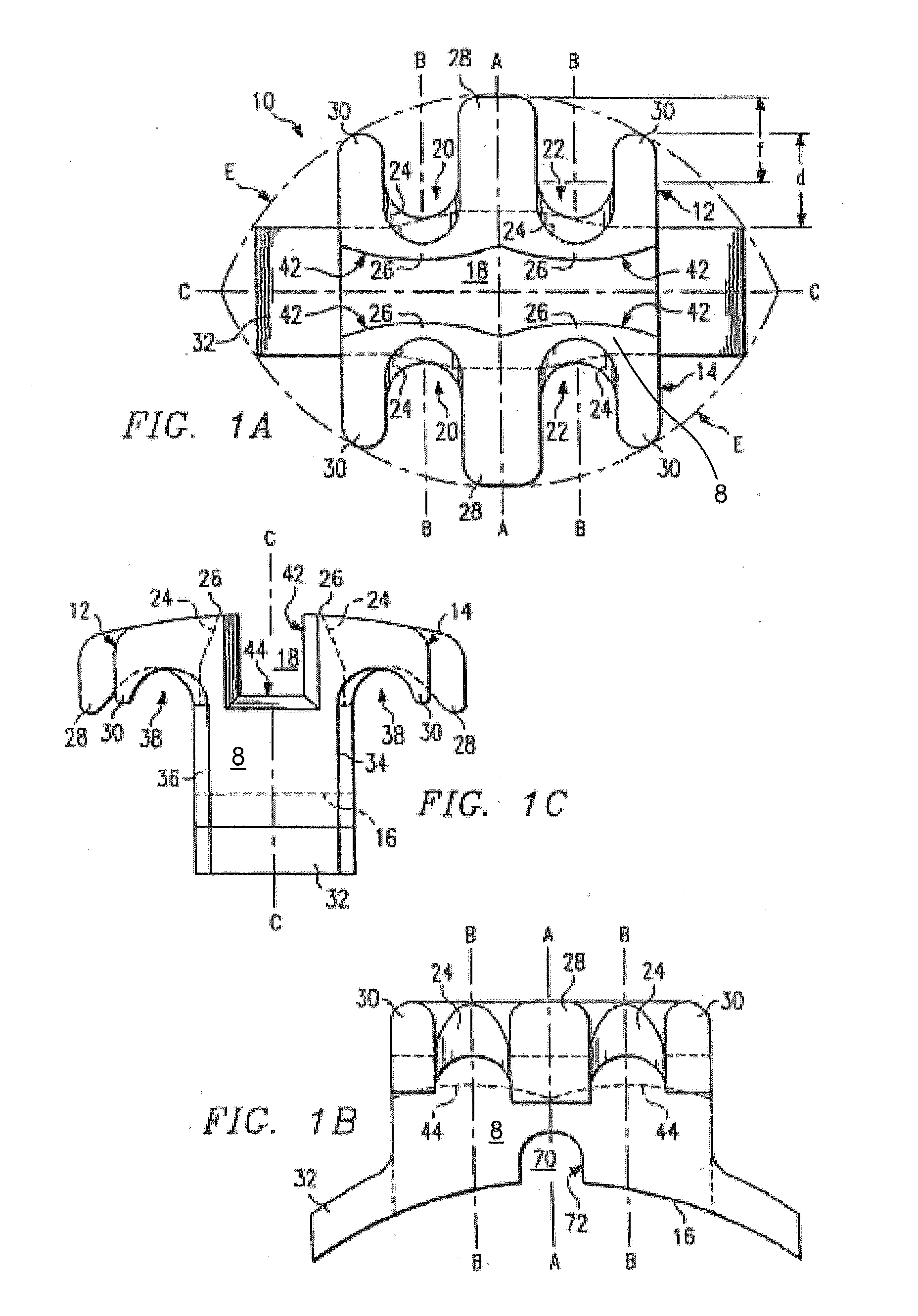

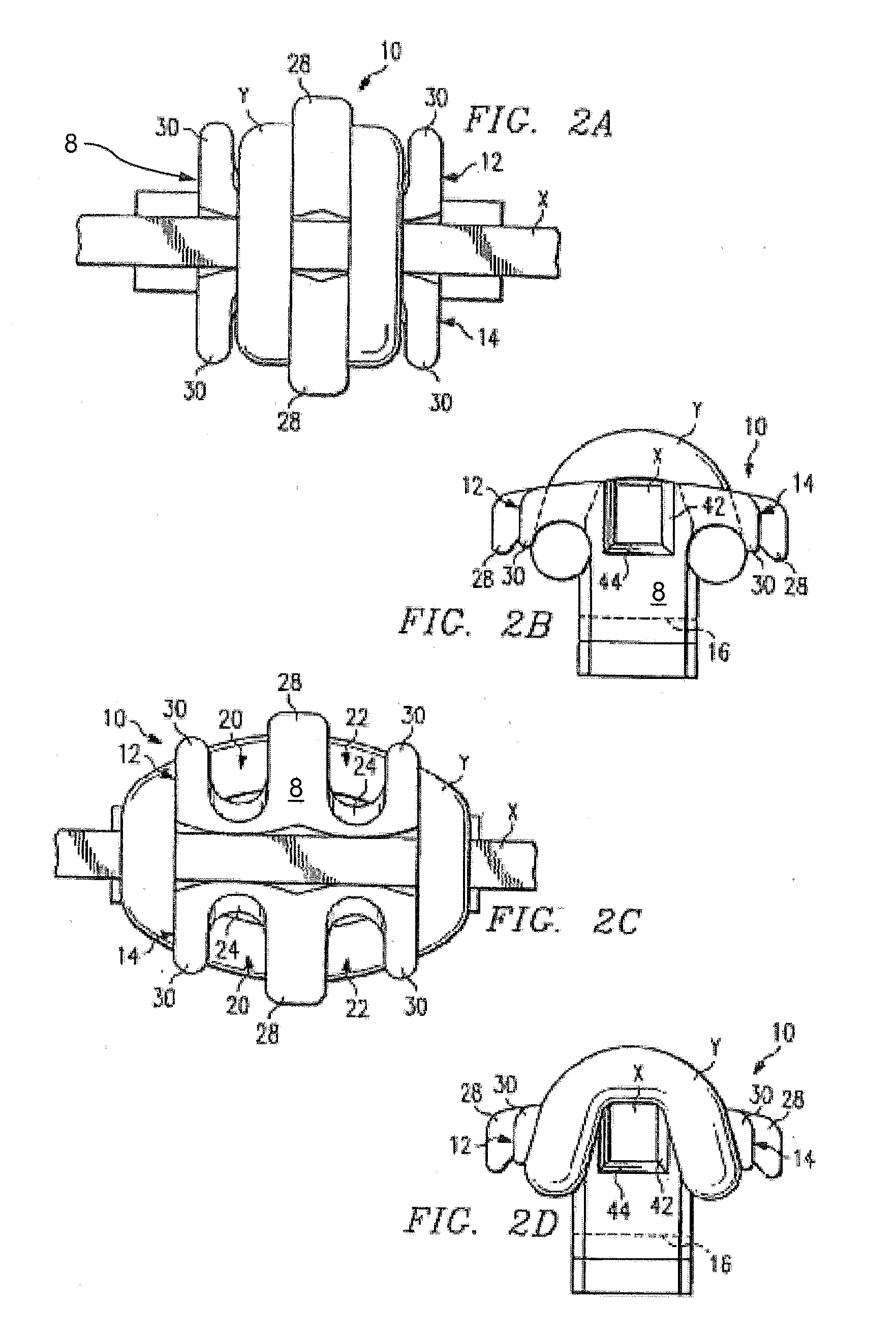

[0118]In the various embodiments of orthodontic brackets, and components thereof described hereinbelow, different embodiments of features or elements having a same general functionality will typically be identified by a label having a same numical portion of the label, but a different letter as a suffix. Thus, for example, various embodiments of a self ligating orthodontic bracket are disclosed hereinbelow, and identified by the numerical label “404”, but at least some of these different embodiments are distinguished from one another by different letters such that different bracket embodiments are identified below as “404”, “404a”, “404b”, etc.

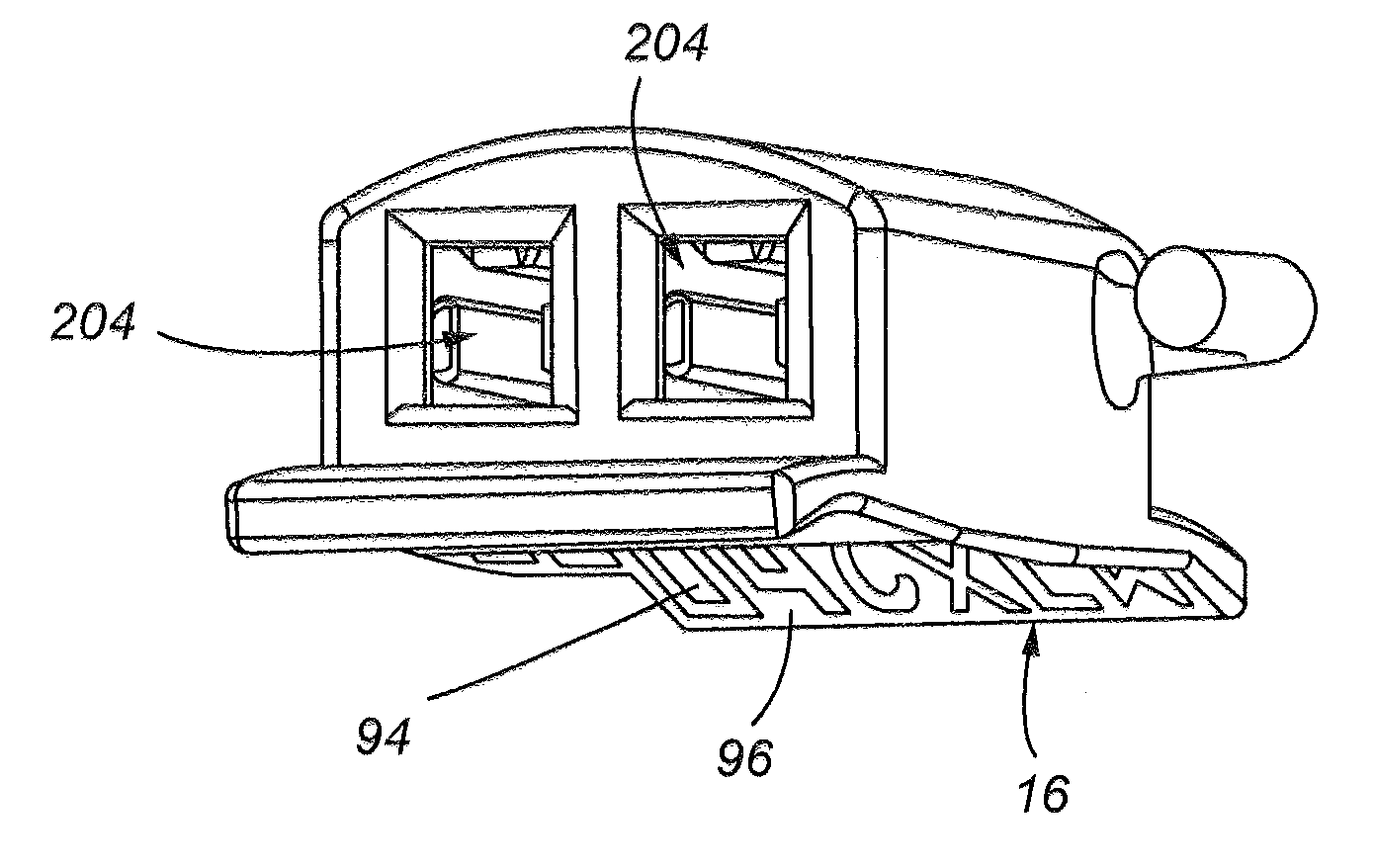

[0119]A self-ligating orthodontic bracket 404 is shown in FIG. 42 having a bracket body 408 with a back 412 and a front surface 416. The bracket body 408 has a left side 420 and right side 424. An archwire slot 428 that has a length generally spanning the extent between the left side 420 to the right side 424 in the front surface 416. Attached...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com