Systems And Methods For Converting Biomass In The Field To A Combustible Fluid For Direct Replacement Or Supplement To Liquid Fossil Fuels

a technology of biomass and combustible fluid, which is applied in the field of biomass conversion systems and methods, can solve the problems of inability to meet the needs of a large-scale production and use of biomass, and achieve the effect of reducing the cost of production and use and improving the efficiency of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

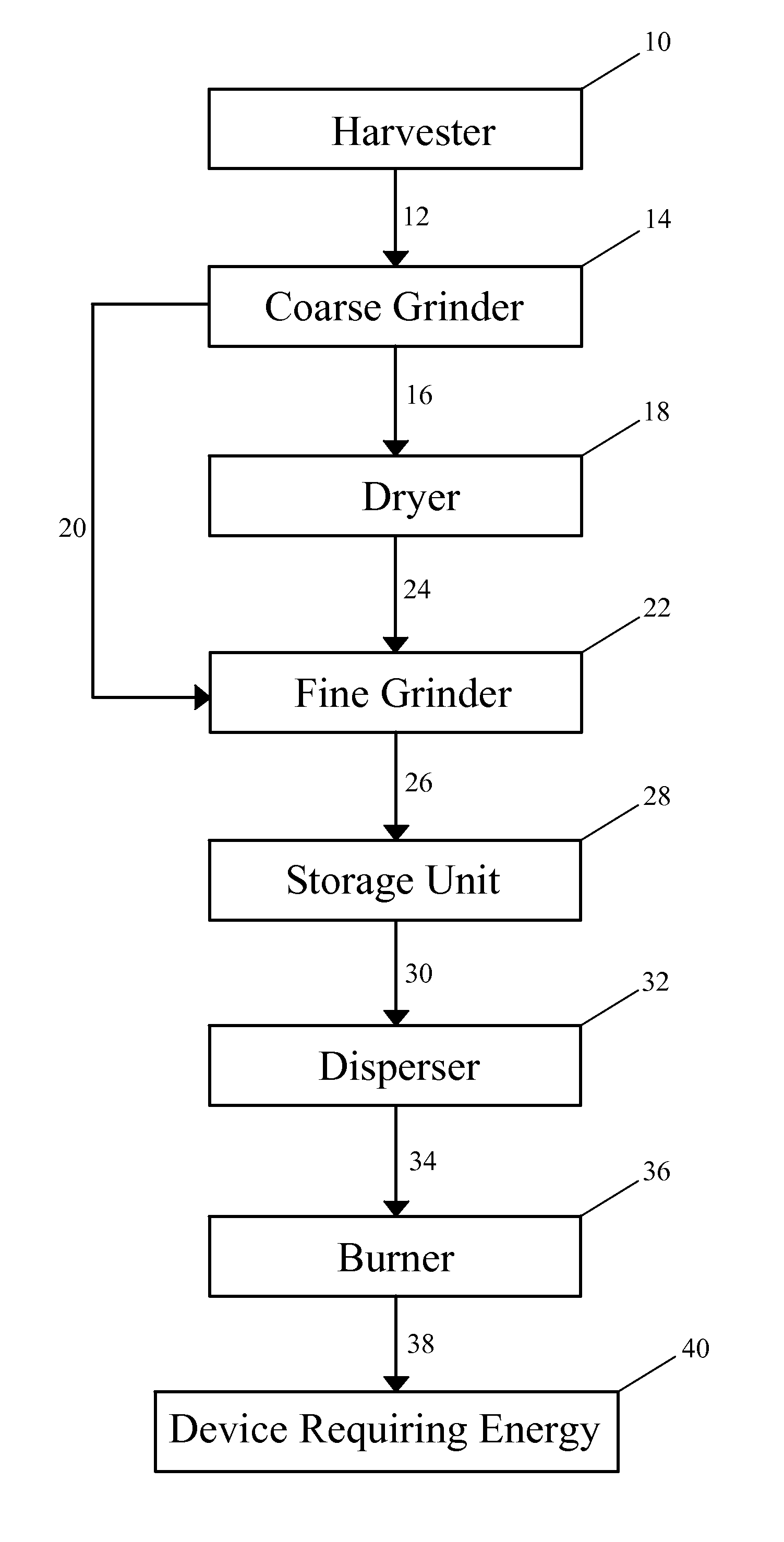

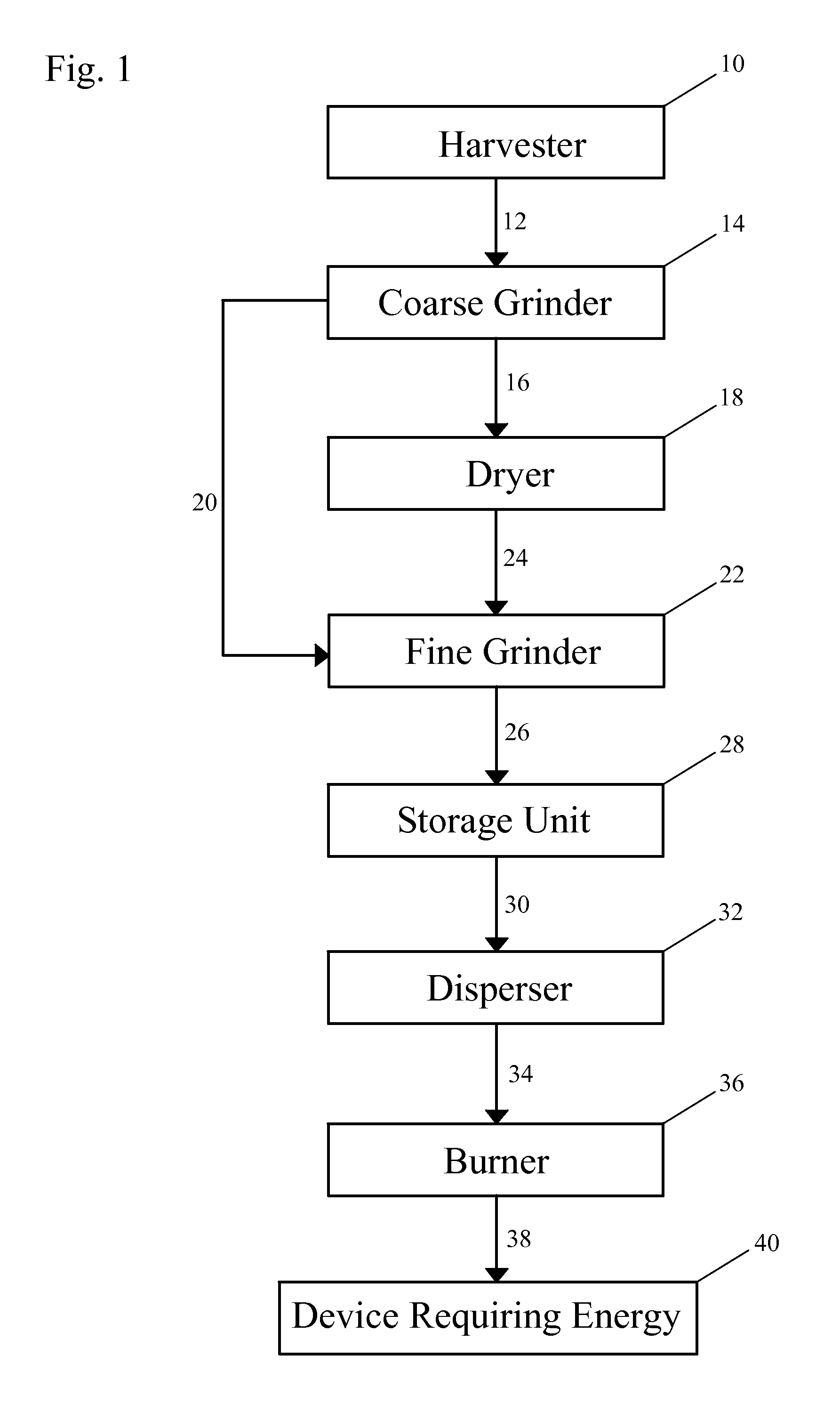

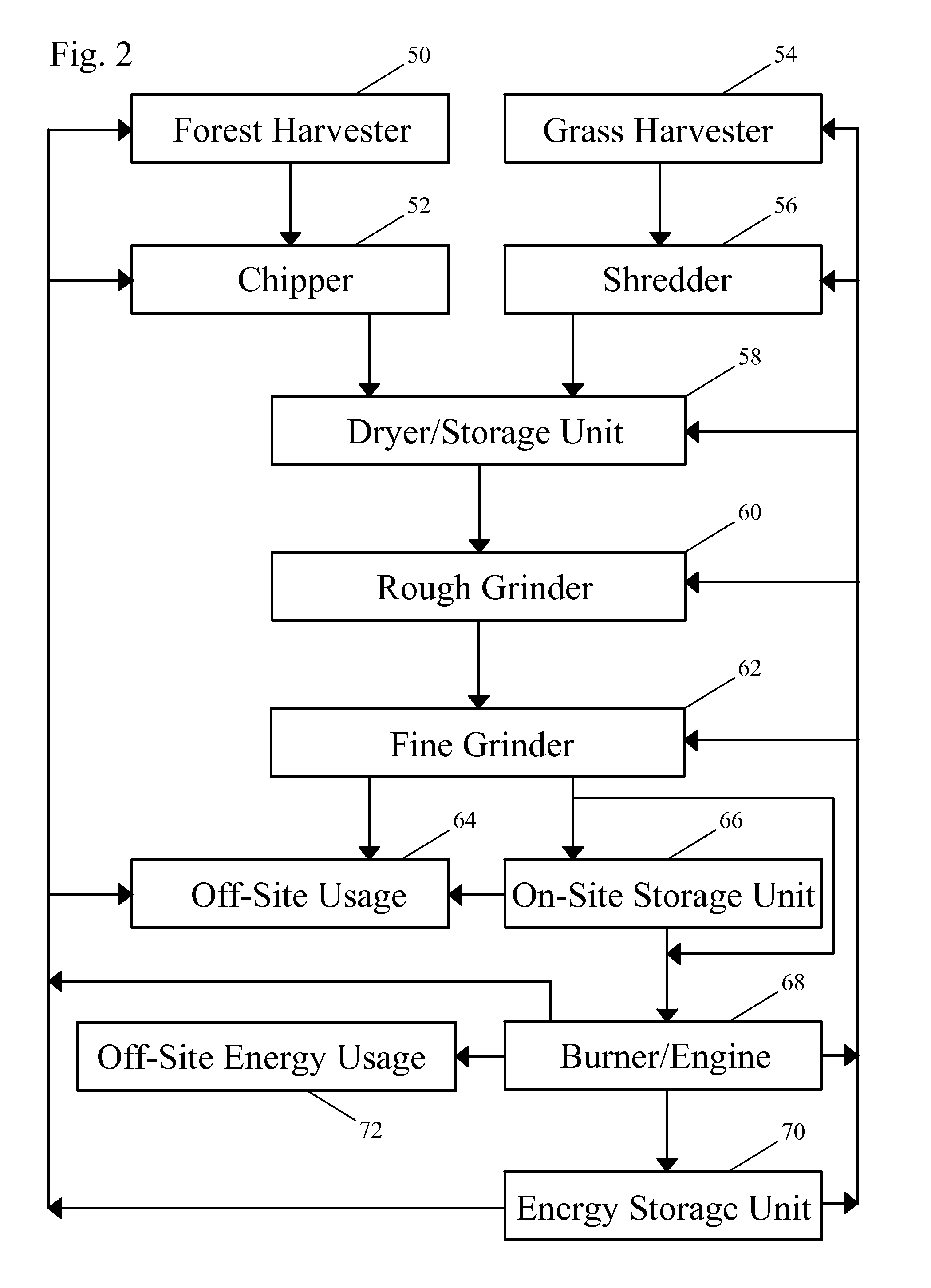

Method used

Image

Examples

Embodiment Construction

[0011]The term “ash” is used herein to describe the incombustible remains of combustion.

[0012]The term “biomass” is used herein to describe any organic matter available on a renewable, or recurring, basis. Biomass may include a wide variety of substances including agricultural residues such as grasses, nut hulls, oat hulls, corn stover, sugar cane, and wheat straw; energy crops such as grasses including but not limited to pampas grass, willows, hybrid poplars, maple, sycamore, switch grass, and other prairie grasses; animal waste from animals such as fowl, bovine, and horses; sewage sludge; wood residues (hardwood and / or softwood) from industries such as logging, milling, woodworking, construction, and manufacturing; and food products such as sugars and corn starch.

[0013]The term “combustion device” is used herein to include any system that burns and / or deflagrates a fuel of any type. Such combustion devices include internal combustion engines, furnaces, grain dryers, and generators...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com