Hybrid drive device

a drive device and hybrid technology, applied in the direction of mechanical actuation clutches, propulsion by capacitors, gearing, etc., can solve the problems of rotary electric machines producing heat, rotary electric machines which require precise control, and heat generation of rotary electric machines, so as to reduce the axial dimension of the entire device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

1. First Embodiment

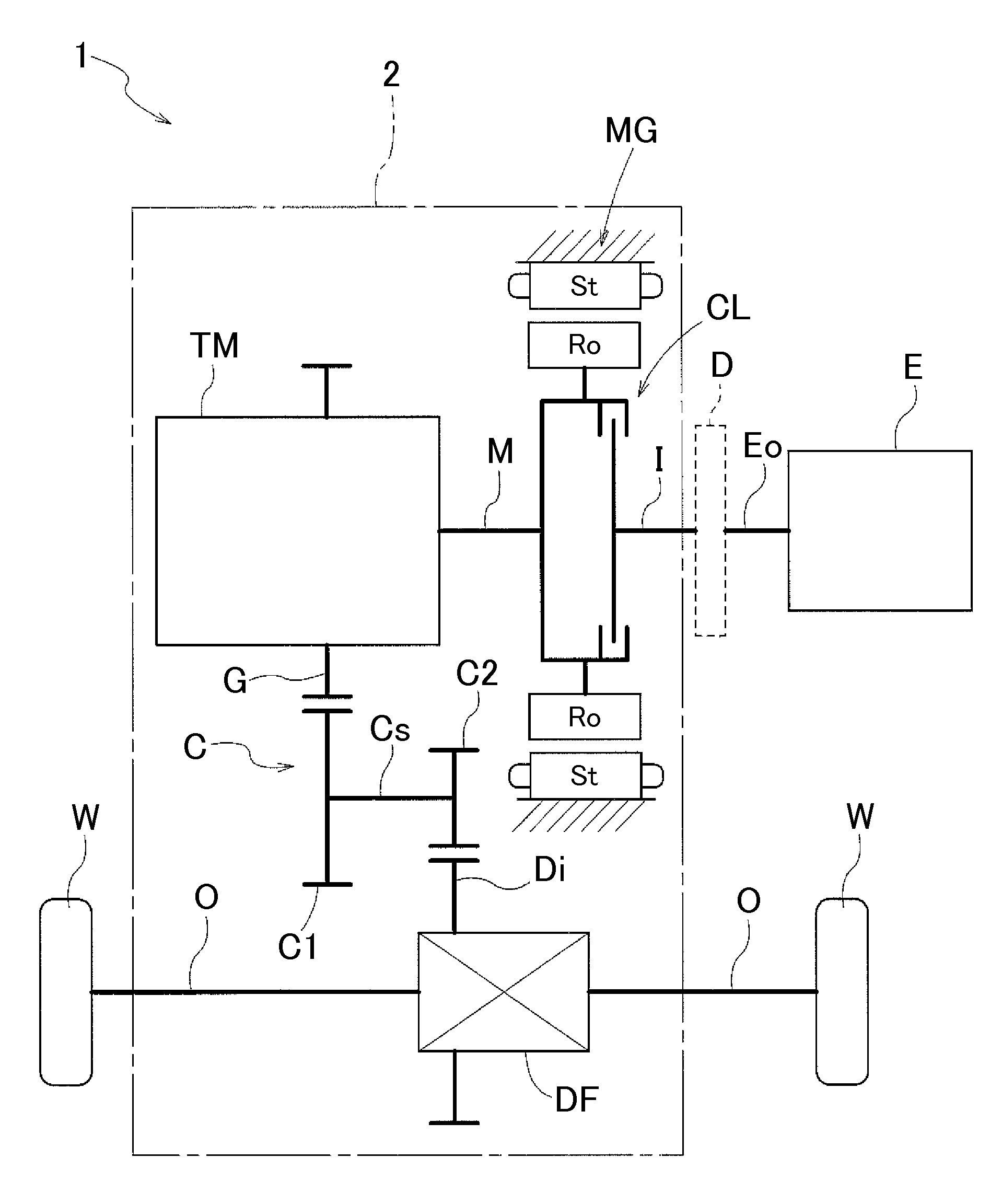

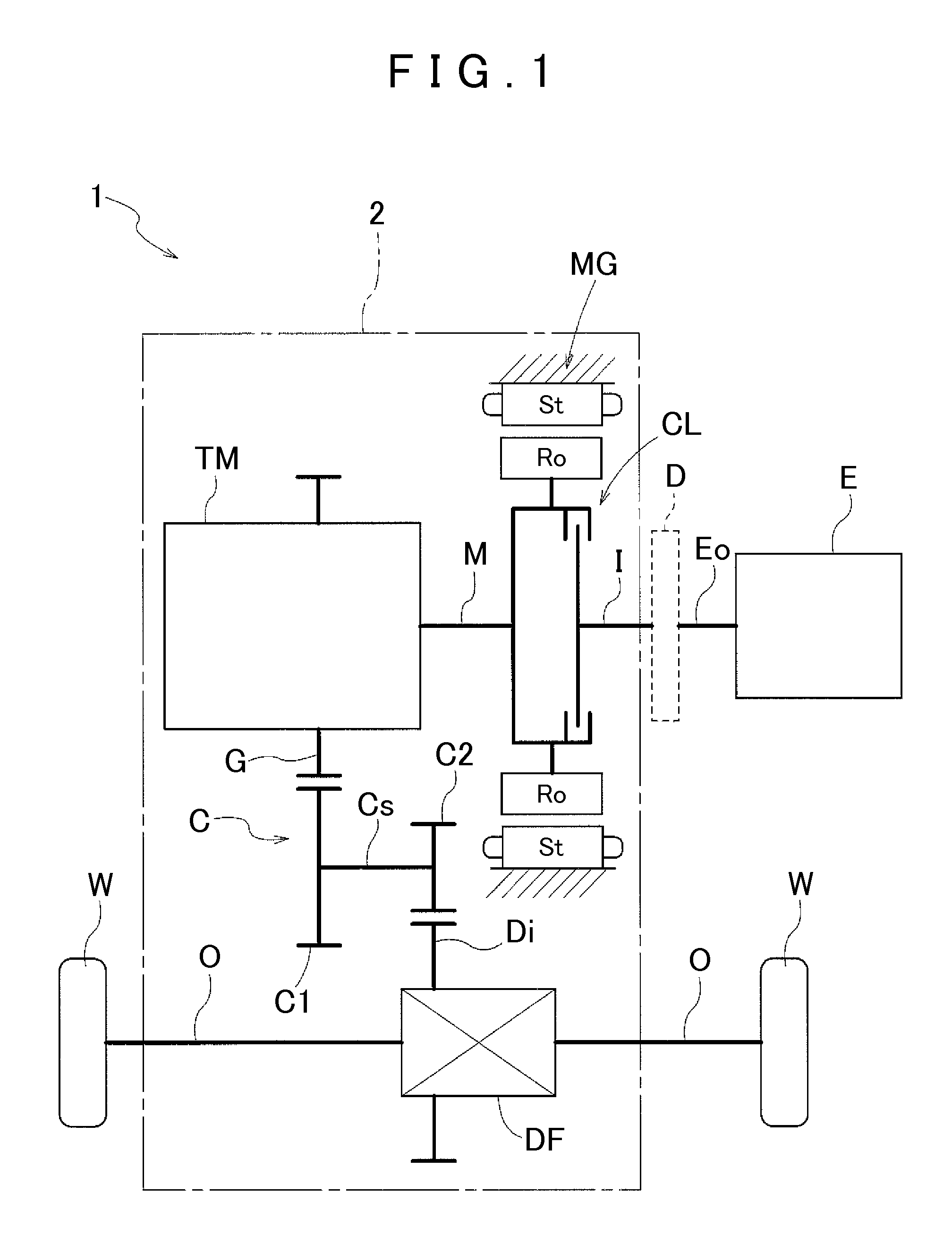

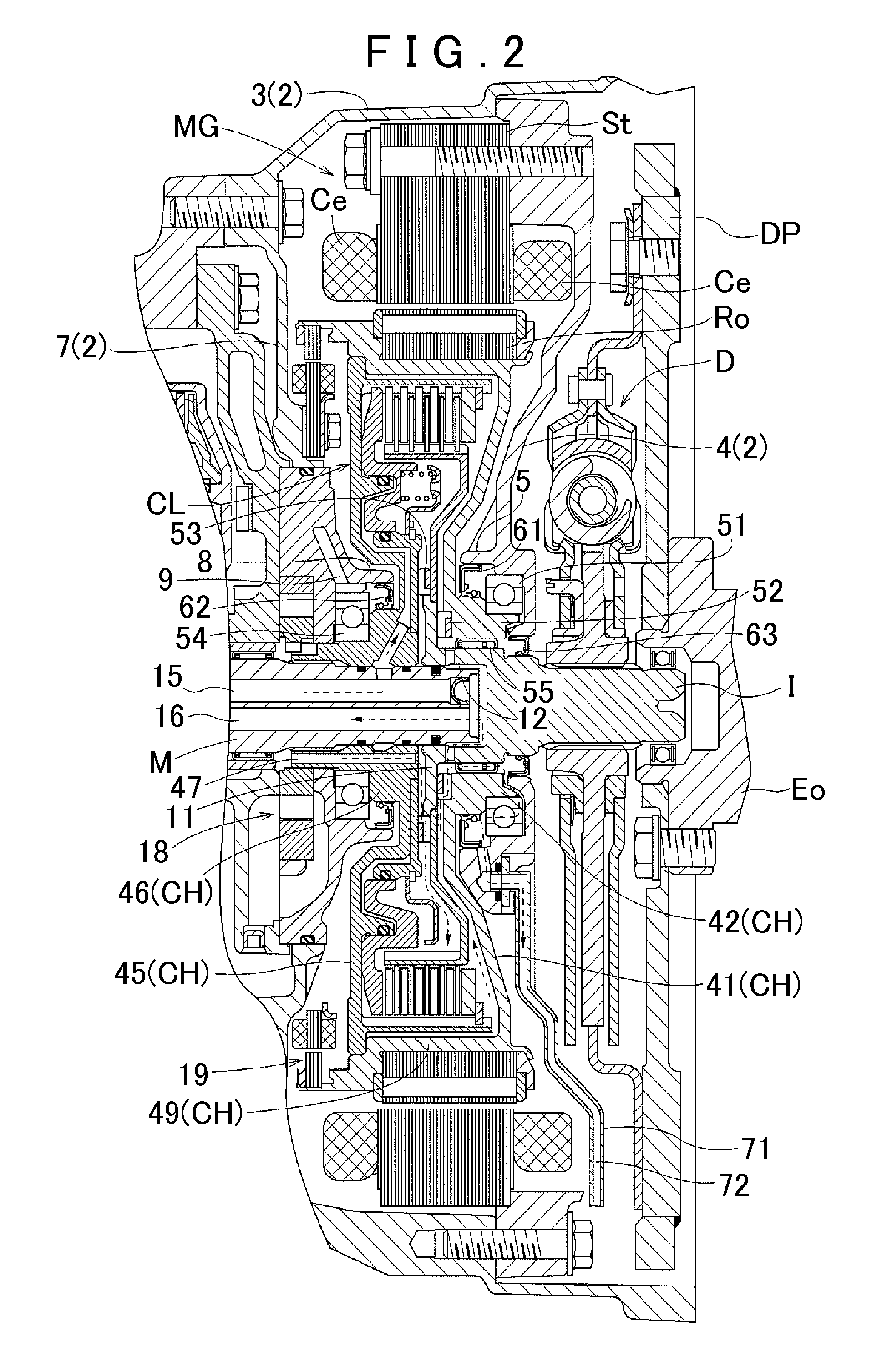

[0036]A first embodiment of the present invention will be described with reference to the drawings. A hybrid drive device 1 is a drive device for a hybrid vehicle that uses one or both of an internal combustion engine E and a rotary electric machine MG as a drive force source for the vehicle. The hybrid drive device 1 is formed as a so-called one-motor parallel type hybrid drive device.

[0037]As shown in FIG. 1, the hybrid drive device 1 according to the embodiment includes an input shaft I drivably coupled to the internal combustion engine E, the rotary electric machine MG, an intermediate shaft M drivably coupled to the rotary electric machine MG and a speed change mechanism TM, a clutch CL provided to switch on and off transfer of a drive force between the input shaft I and the intermediate shaft M, and a case 2 that houses the input shaft I, the intermediate shaft M, the clutch CL, and so forth. The hybrid drive device 1 according to the embodiment configured a...

second embodiment

2. Second Embodiment

[0090]A second embodiment of the present invention will be described with reference to the drawings. The overall configuration of the hybrid drive device 1 according to the embodiment and the configuration of respective sections of the hybrid drive device 1 are basically the same as those in the above first embodiment. In the embodiment, however, the arrangement of the rotatably supporting structure and the sealing structure for the clutch housing CH with respect to the case 2 on the other side in the axial direction with respect to the clutch housing CH is partially different from that in the above first embodiment. Thus, the differences from the above first embodiment will be mainly described in detail below. The same elements as those in the above first embodiment will not be specifically described.

[0091]In the embodiment, as shown in FIG. 4, no stepped portion in the axial direction (the stepped portion 46a in the above first embodiment; see FIG. 3) is formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com