Method of using contaminated water from an oilwell effluent stream

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

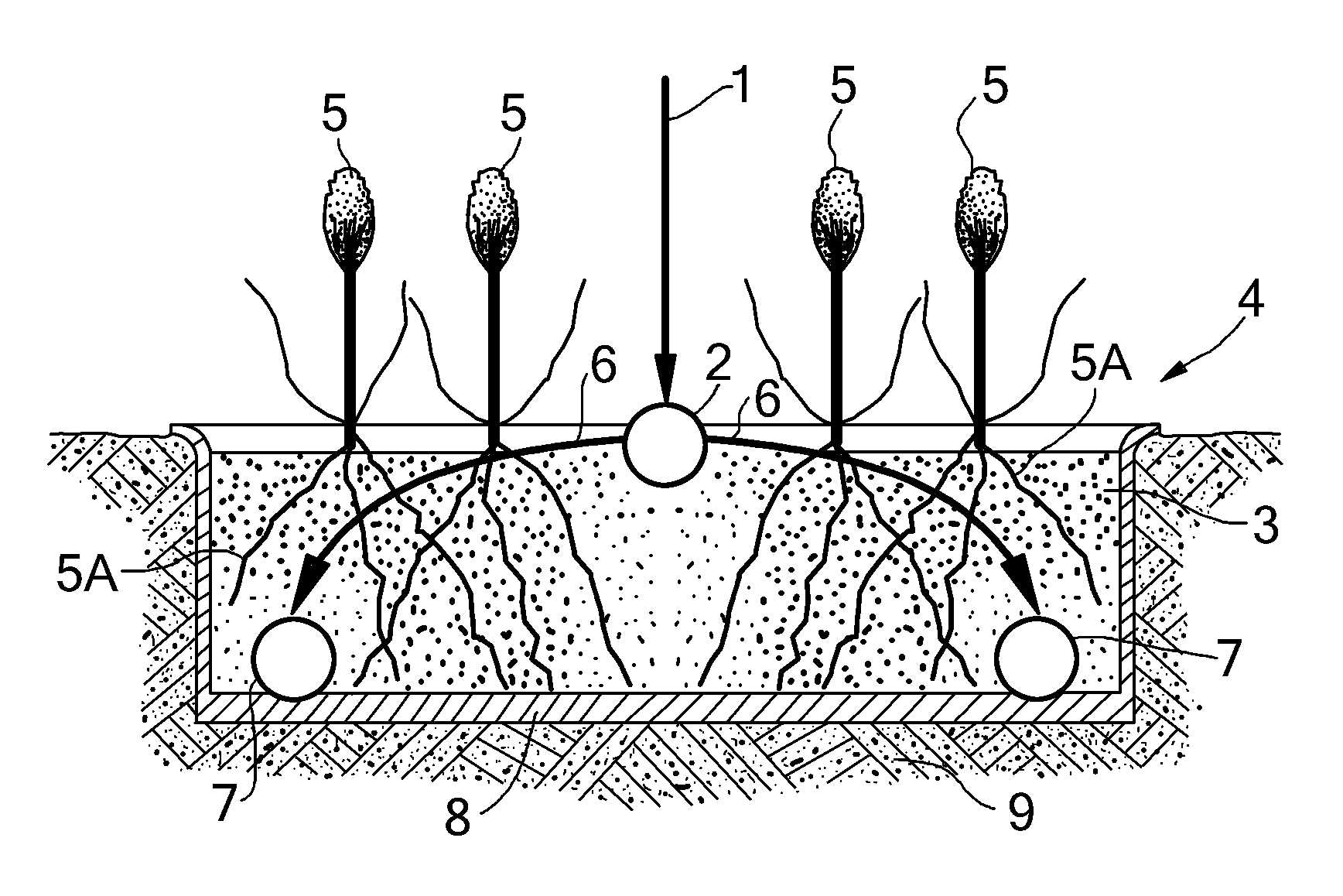

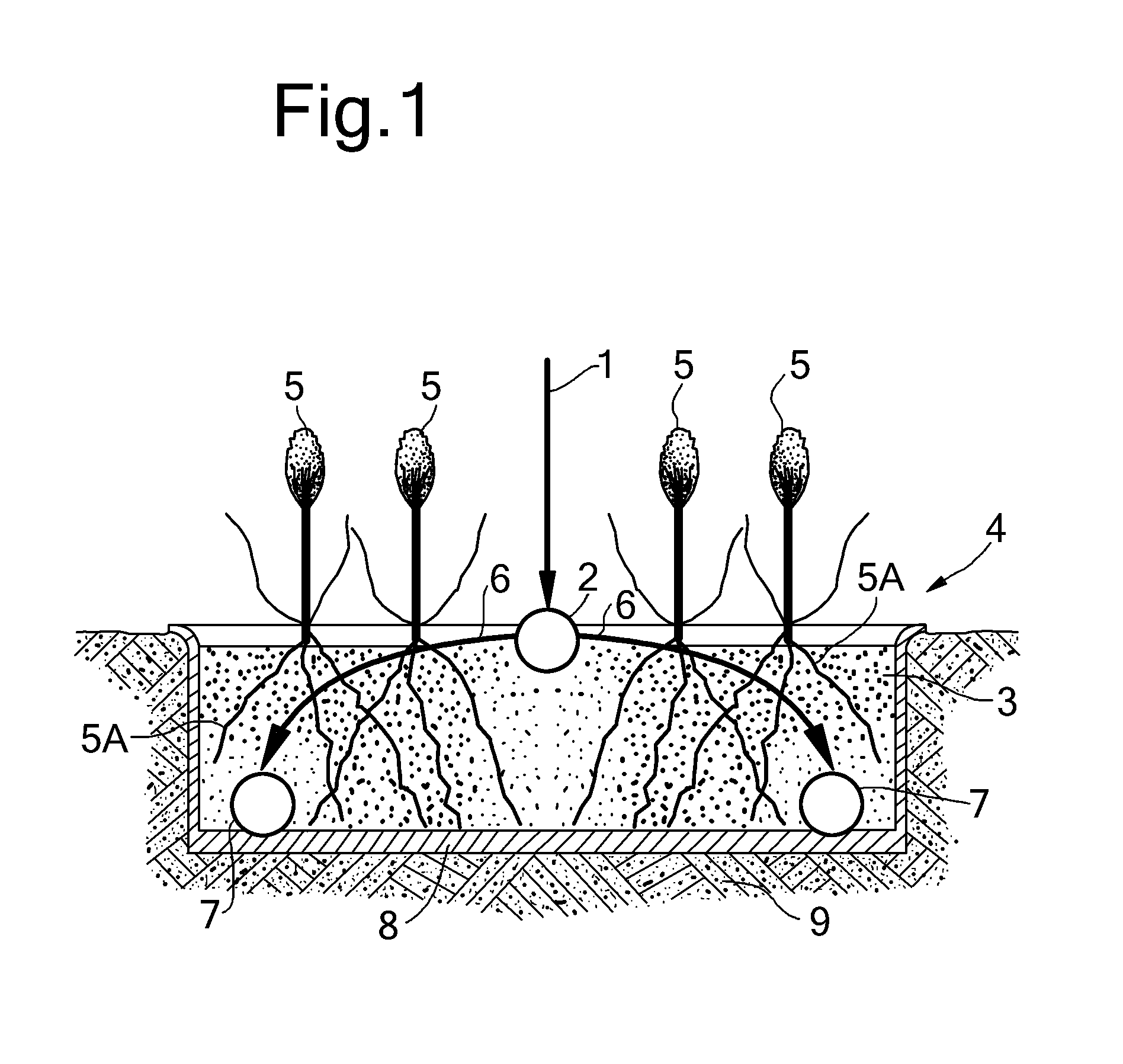

[0025]FIG. 1 shows how a flux of wastewater 1 comprising a capped amount of salt, boron and crude oil is fed via a permeable irrigation conduit 2 into the soil 3 of a reed bed 4 on which reed plants 5 are growing and consume irrigation water flowing through the soil 3, as illustrated by arrows 6, towards a pair of permeable drainage pipes 7 that are embedded in the soil 3 above an impermeable liner 8. The roots 5A of the reed plants 5 suck up wastewater 1 and bacteria living in the soil 3 around the roots 5A of the reed plants 5 break down the crude oil and thereby reduce the crude oil content of the wastewater through biodegradation, thereby creating a flux of unused irrigation water with a reduced crude oil content flowing into the drainage pipes 7, such that the unused irrigation water contains such a small amount of crude oil that it can be fed to an irrigation system for irrigating for example eucalyptus trees, which are less tolerant to irrigation water contaminated with crude...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com