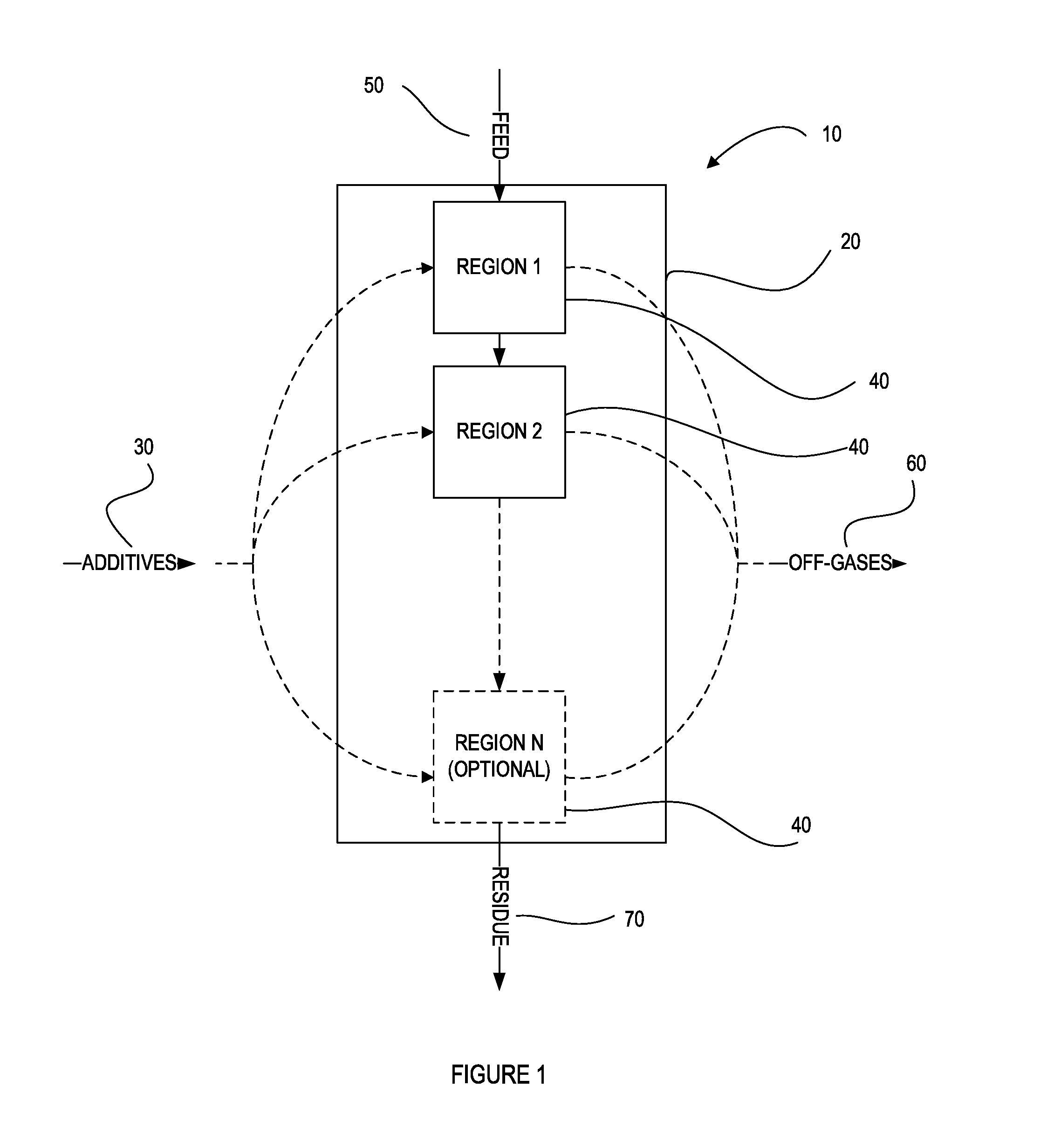

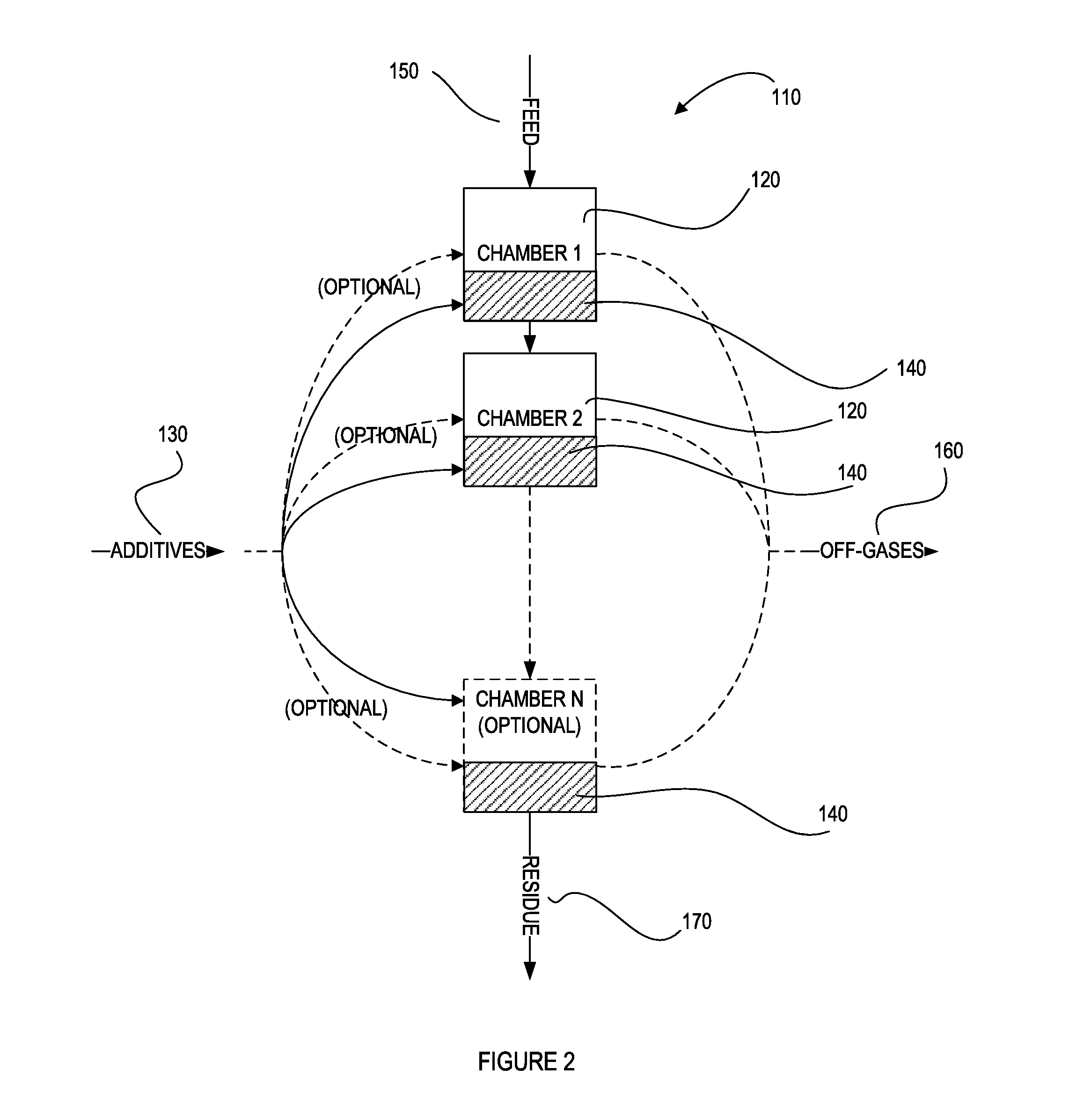

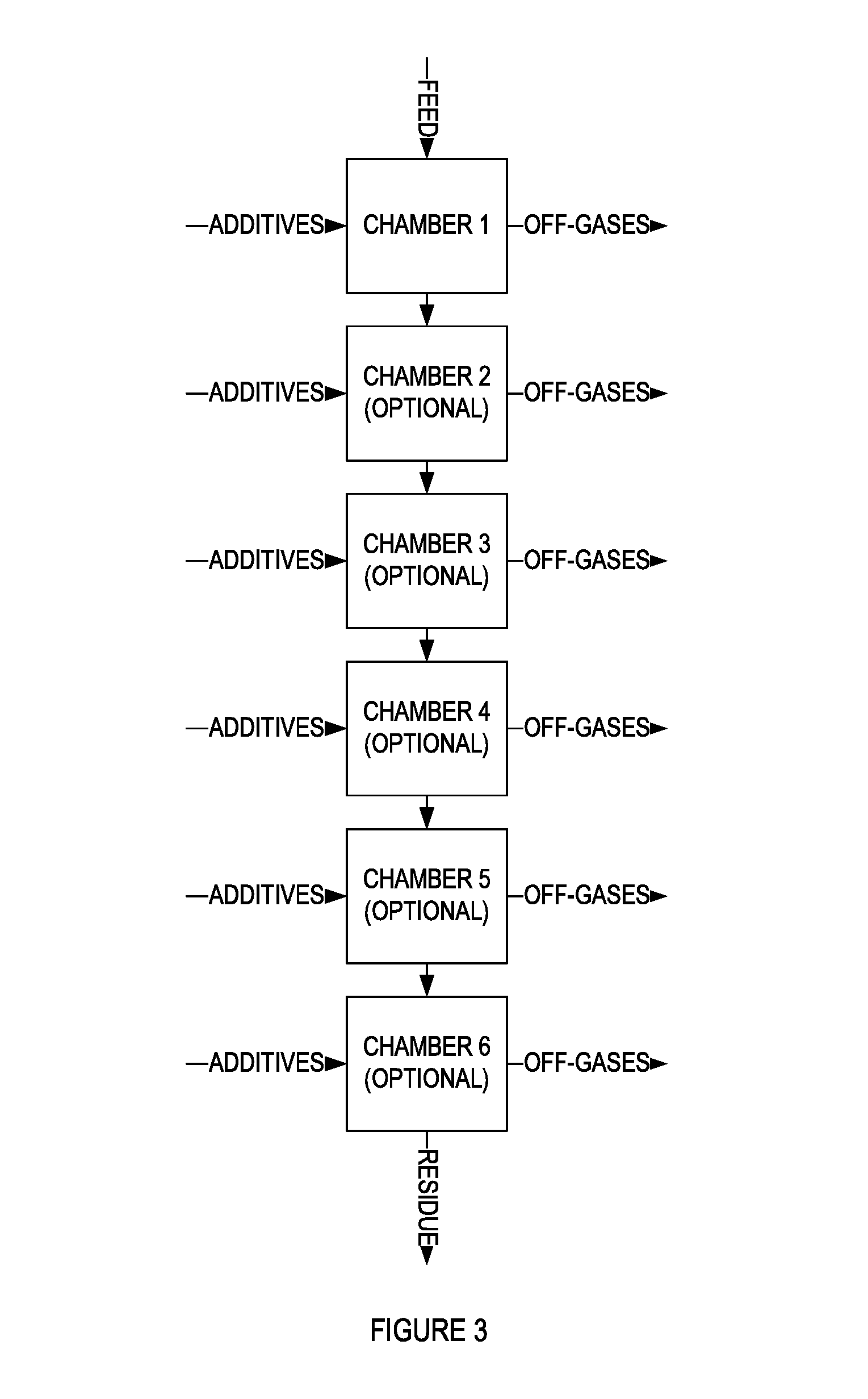

Gasifier comprising vertically successive processing regions

a gasifier and processing region technology, applied in the field of gasification, can solve the problems of insufficiently addressing the problems of prior systems and processes in vertically oriented gasifiers, the inability to achieve significant commercial use of the practicable efficient system, and the rise of the temperature in the gasifier often above the slagging temperatur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Definitions

[0055]As used herein, the term ‘about’ refers to a + / −10% variation from the nominal value. It is to be understood that such a variation is always included in any given value provided herein, whether or not it is specifically referred to.

[0056]The terms ‘carbonaceous feedstock’ and ‘feedstock’, as used interchangeably herein, are defined to refer to carbonaceous material that can be used in the gasification process. Examples of suitable feedstock include, but are not limited to, hazardous and non-hazardous waste materials, including municipal wastes; wastes produced by industrial activity; biomedical wastes; carbonaceous material inappropriate for recycling, including non-recyclable plastics; sewage sludge; coal; heavy oils; petroleum coke; heavy refinery residuals; refinery wastes; hydrocarbon contaminated solids; biomass; agricultural wastes; municipal solid waste; hazardous waste and industrial waste. Examples of biomass useful for gasification include, but are not lim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressures | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com