Method of Packaging and Package for Sensors

a sensor and packaging technology, applied in the field of sensors packaging and packaging, can solve the problems of compromising the sterilization of the sensor, reducing the shelf life of the sensor, compromising the performance of the device, etc., and achieve the effects of preventing the damage of the sensor, limiting the negative effects of sterilization on the sensor, and maintaining sterility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]As used in the specification, and in the appended claims, the singular forms “a”, “an”, “the”, include plural referents unless the context clearly dictates otherwise. The term “comprising” and variations thereof as used herein is used synonymously with the term “including” and variations thereof and are open, non-limiting terms.

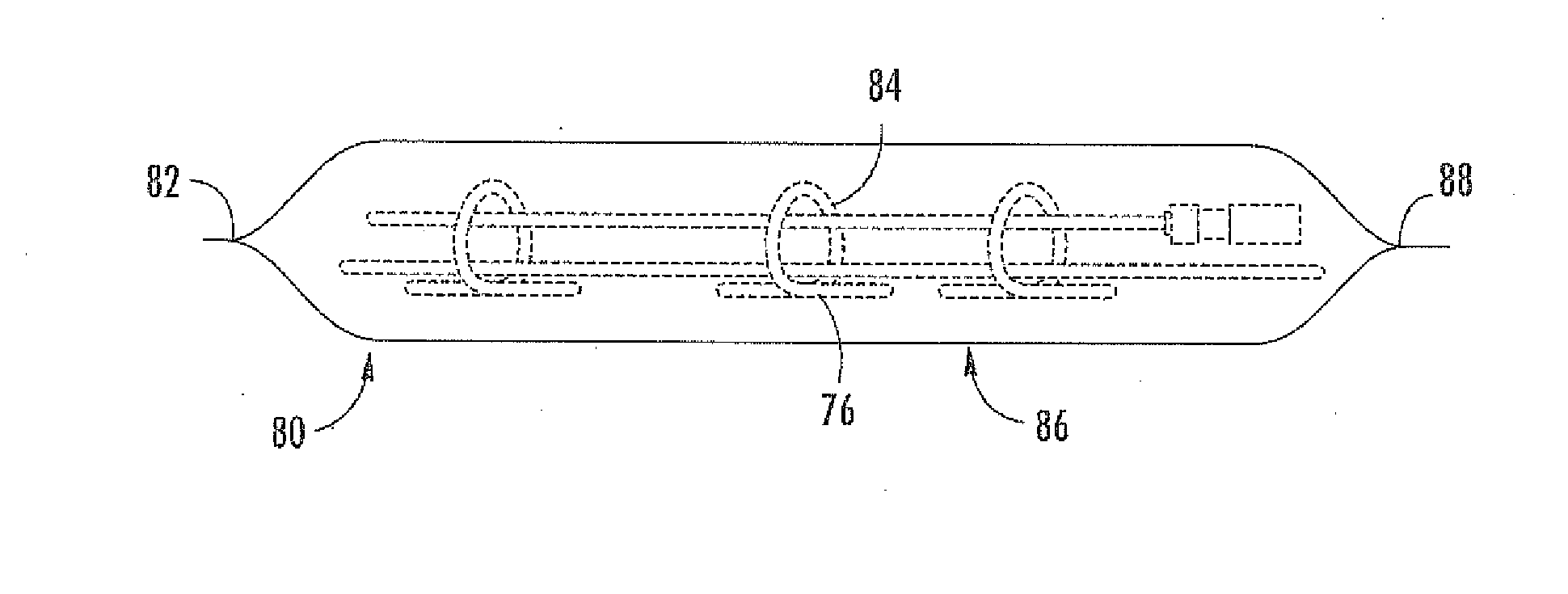

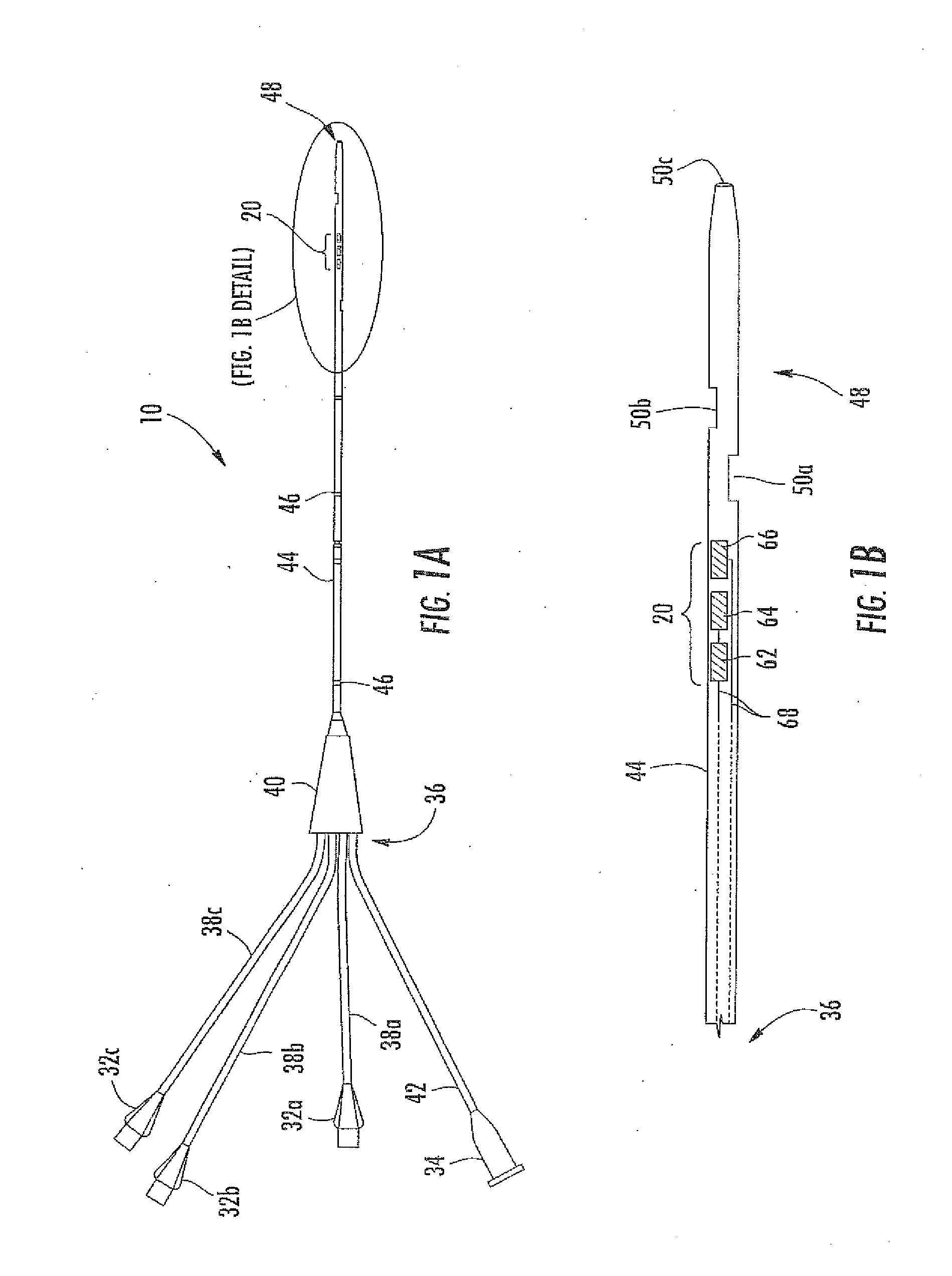

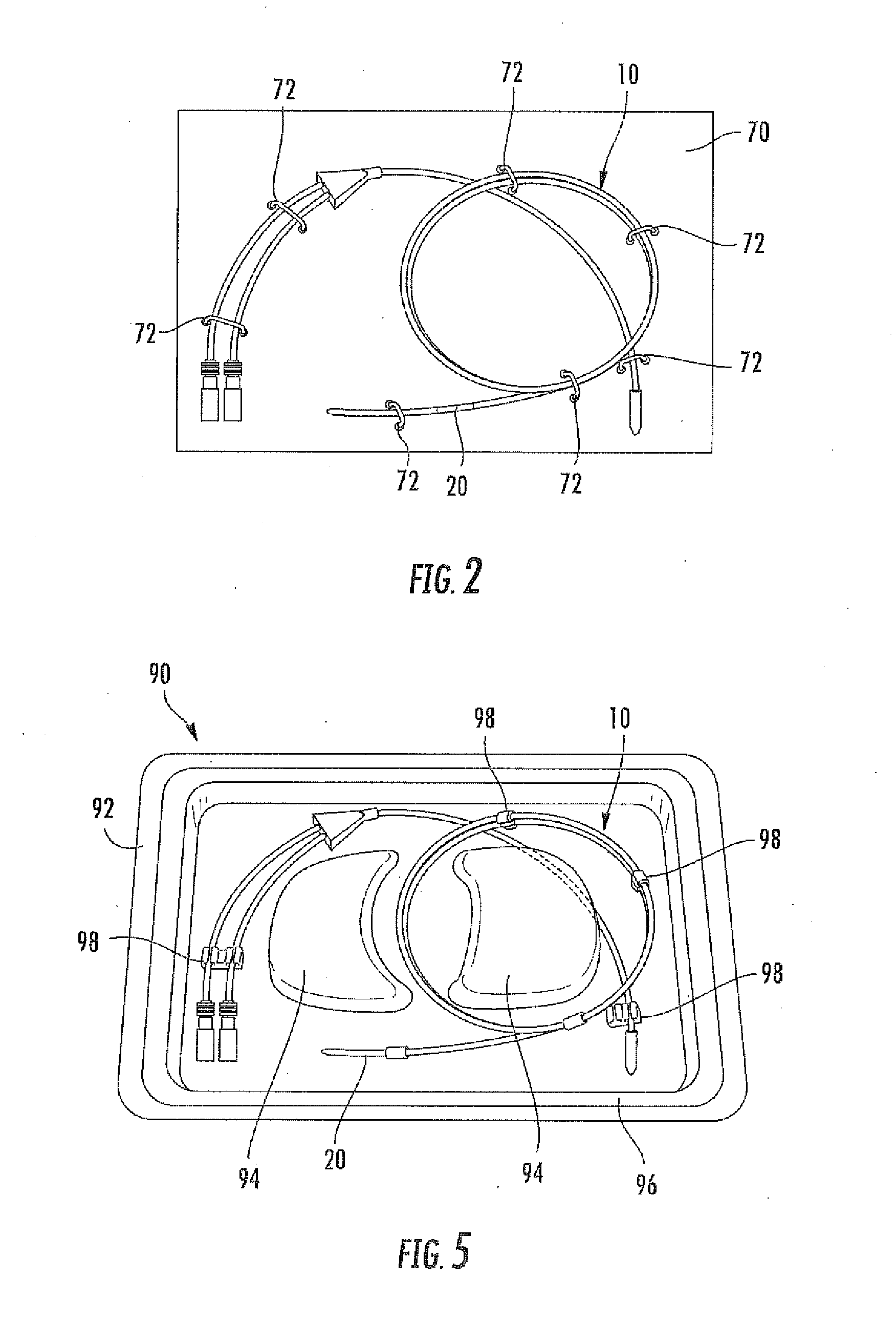

[0024]Methods of limiting possible damage to the sensor or the packaging material during shipping comprise providing an enzyme sensor such as a glucose oxidase sensor in a gas impermeable package. The methods can also limit the negative effects of sterilization on enzyme sensors.

[0025]In the normal process for producing a package and providing the sensor within the package, the package can include one or more of oxygen and water. Furthermore, regardless of the process used to produce the package and the desire to minimize the bioburden, microorganisms will generally exist in the package. In the packaging methods, a significant portion of the oxygen and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com