Heat exchanger for bathing shower

a technology for heat exchangers and bathing showers, applied in indirect heat exchangers, light and heating apparatuses, laminated elements, etc., to achieve the effects of improving heat exchange efficiency, increasing energy saving effect, and simplifying structure and supporting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

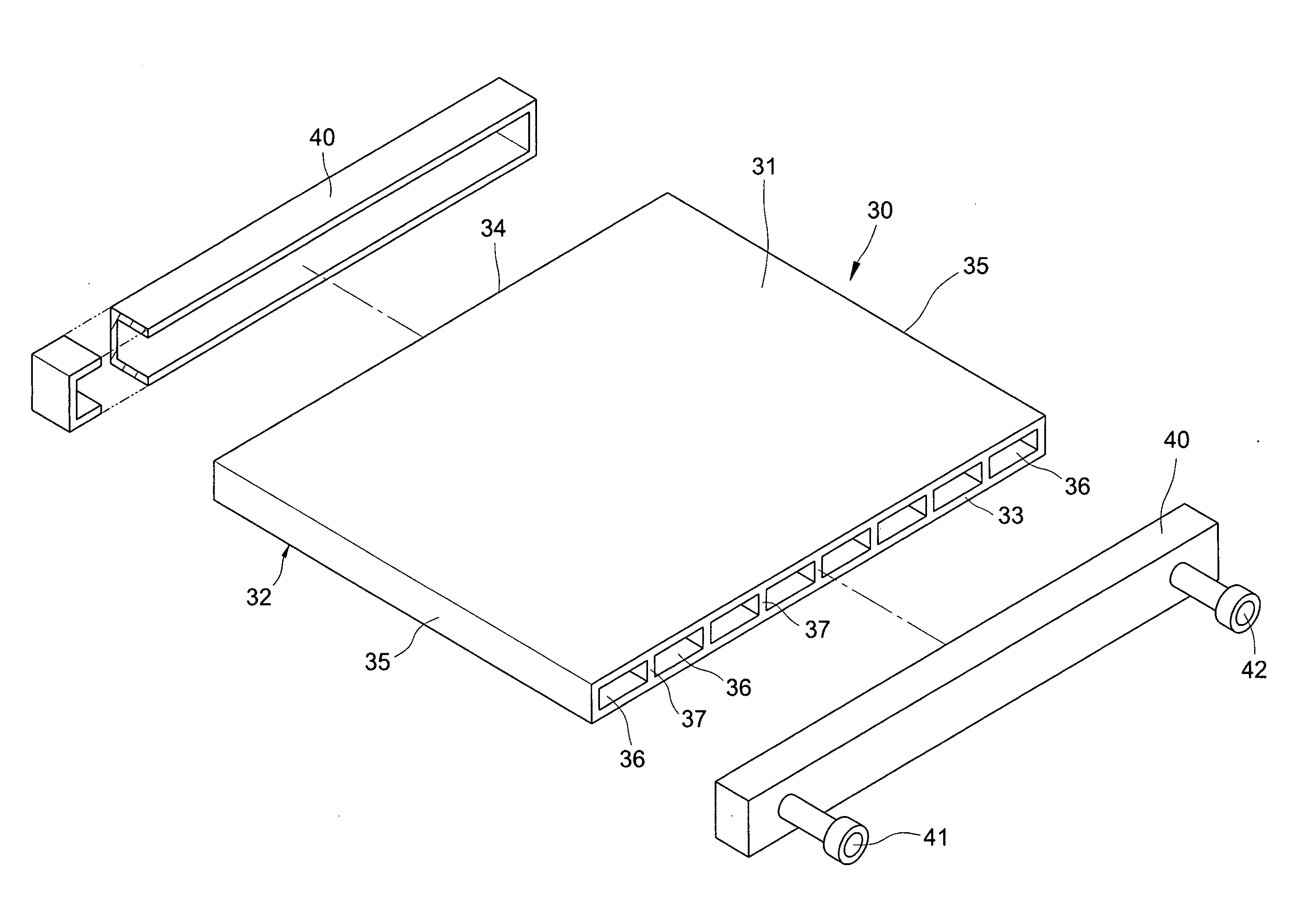

[0026]FIG. 6 through FIG. 8, a “heat exchanger for bathing shower” of the present invention includes a heat exchanging slab 30 and two sealing covers 40 such that one of the sealing covers 40 is created with a water intake 41 and a water outtake 42, wherein:

[0027]The heat exchanging slab 30, which is a flat planar cuboid extruded by alloy metal material, includes a flat top surface 31, a flat bottom surface 32, a front hatch 33, a rear hatch 34, two parallel upright flanks 35, a plurality of parallel water passages 36 penetrated through between the front hatch 33 and rear hatch 34 such that each pair adjacent water passages 36 is partitioned by a septum 37 with a circulating bore 38 created thereon in interlaced stagger manner, which means a bore in upper section of one septum and another bore in lower section of the other septum for each pair of adjacent septa 37 (as shown in FIG. 7); and

[0028]each of two sealing covers 40 respectively covers on the front hatch 33 and rear hatch 34...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com