Retractable catheter

a catheter and retraction technology, applied in the field of retraction catheters, can solve the problems of reducing affecting the service life of the pull wire, so as to avoid an increase in the diameter of the outer sheath, improve the connection, and strengthen the tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]In the following, the expressions “distal”, meaning away from the operator's side, and “proximal”, meaning towards the operator's side, are used.

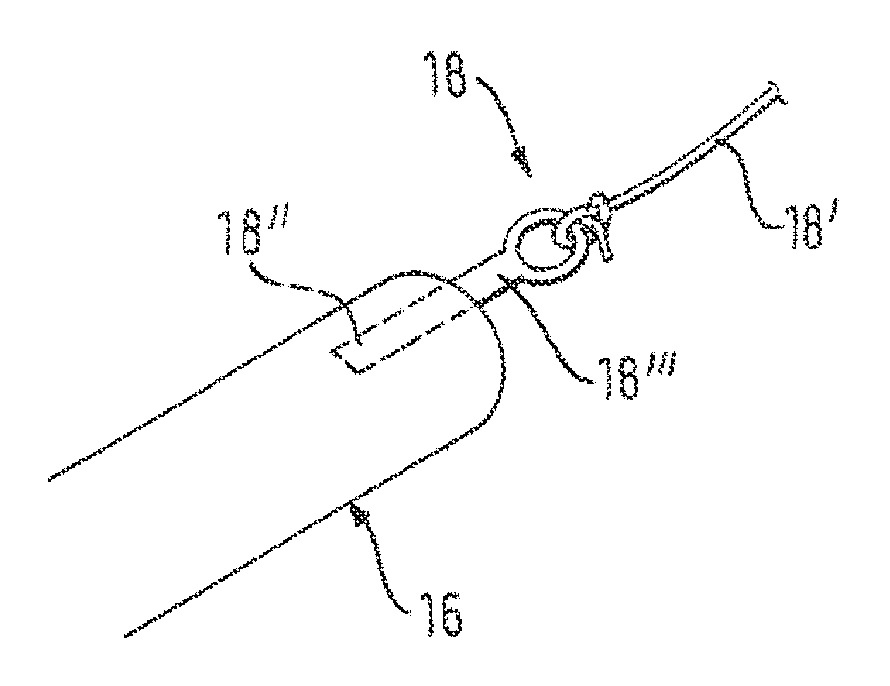

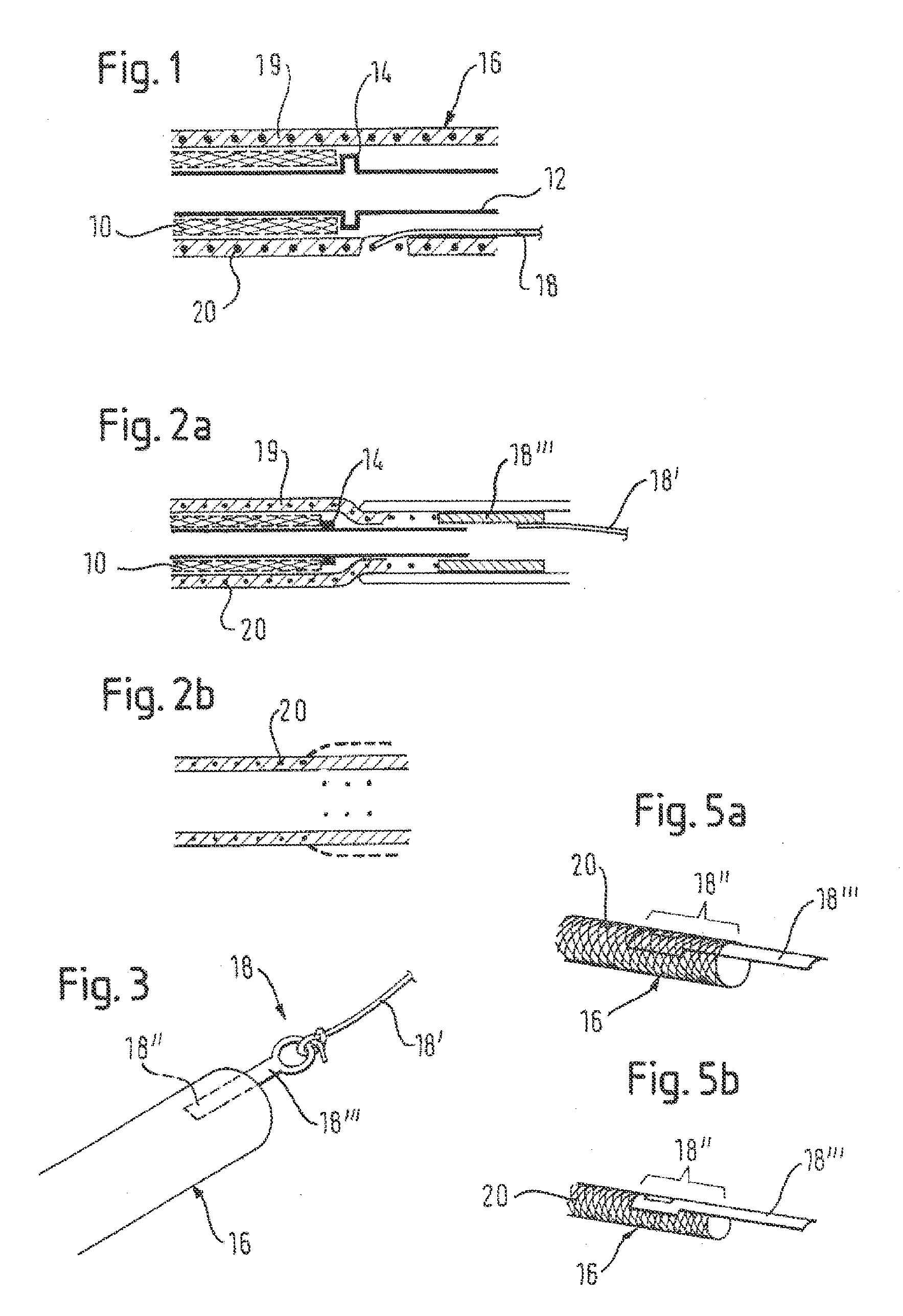

[0032]Referring to FIG. 1, a self-expanding implant 10, known as a stent, is placed around a shaft tube 12 and abuts on an abutment member 14 that can be formed integrally with the shaft tube 12 or can be a separate member, as for example a ring clamped or otherwise fixed on the shaft tube. The shaft tube 12 can be strengthened by a supporting member, such as a steel spring wound tightly to resist compression but to allow off-axis flexibility, in particular if the implant is very long.

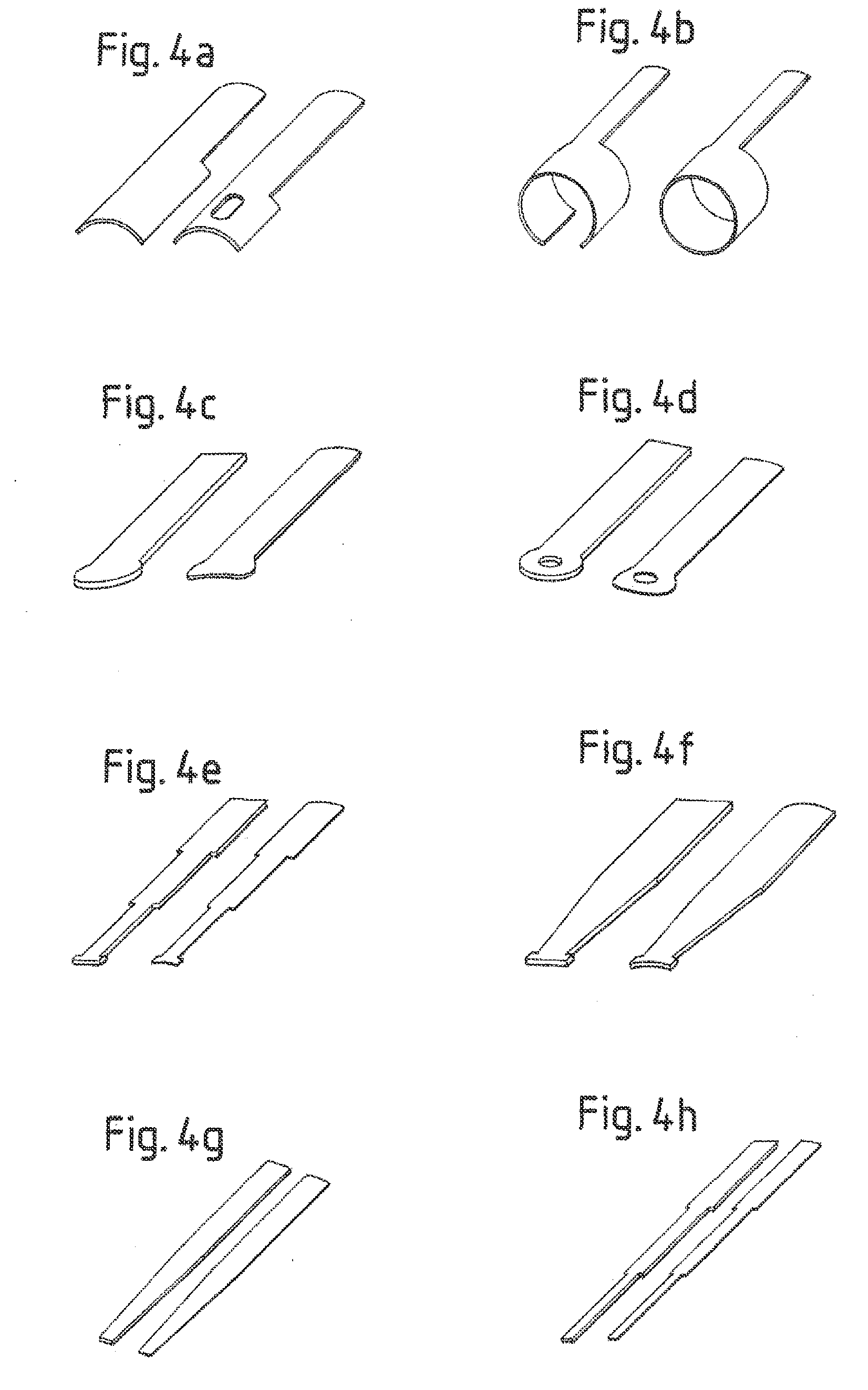

[0033]Around this arrangement is disposed an outer catheter sheath 16 that covers the distal end portion of the shaft tube 12 and the implant 10. The outer catheter sheath 16 extends longitudinally from a distal end in a proximal direction. The outer sheath 16 may extend substantially the whole length of the delivery system, but preferably is not signifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com