Apparatus, system, and method sewing

a sewing machine and sewing system technology, applied in the field of apparatus, system and method sewing, can solve the problems of professionals without access to sewing machines, inability to purchase sewing machines, and inability to sew with a machine, so as to facilitate sewing, facilitate the sewing process, and optimize the exposure of the sewing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

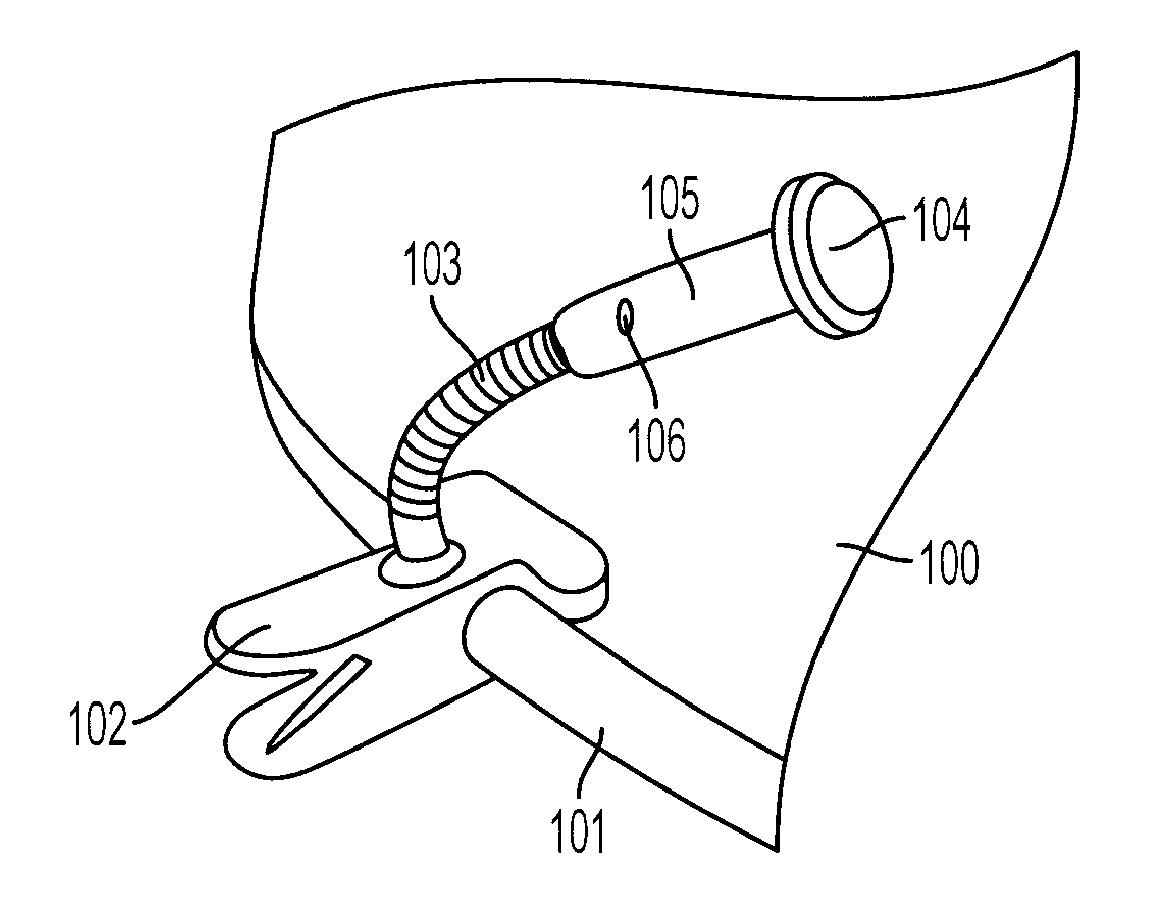

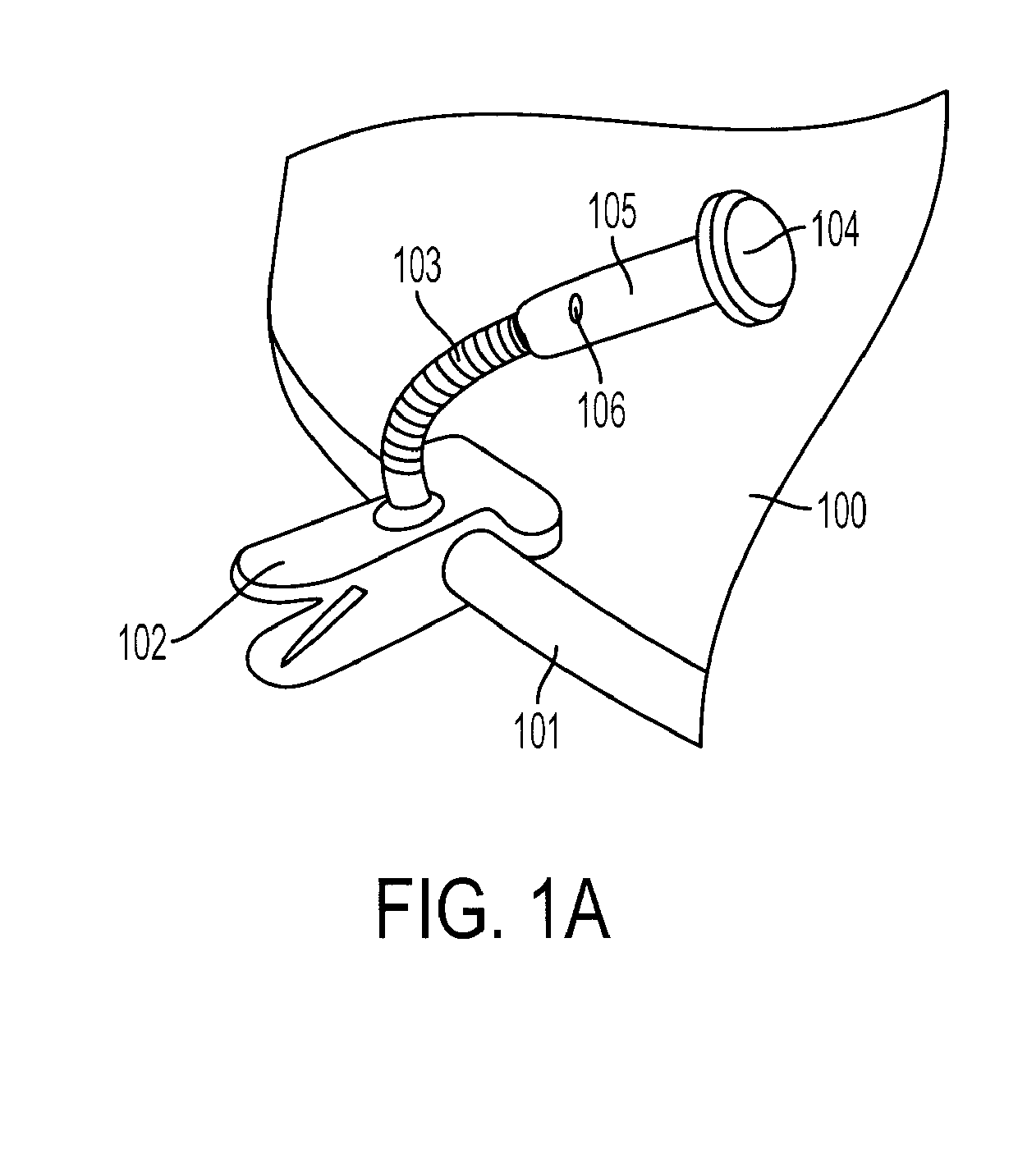

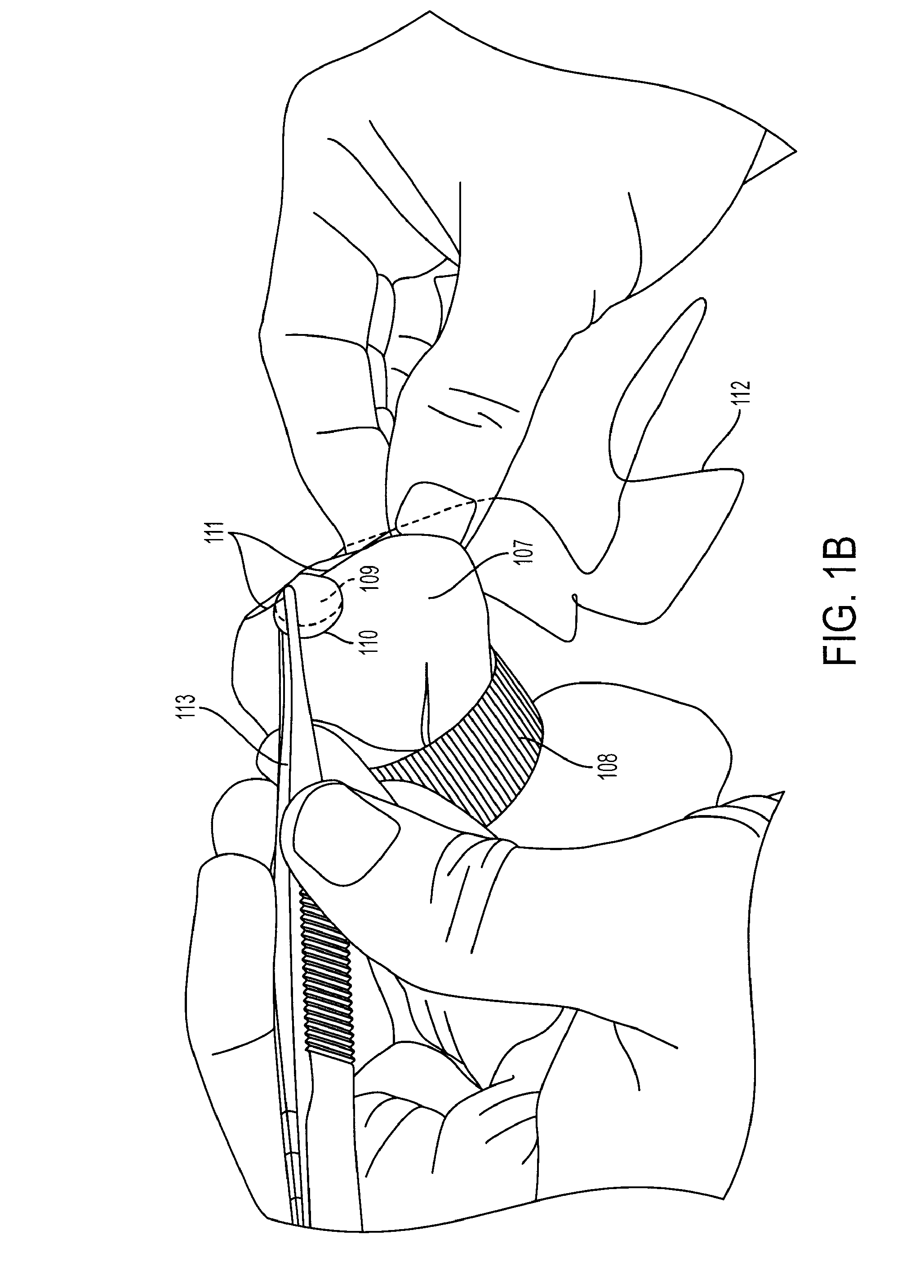

[0050]Although most sewing today is done with machines, sewing by hand is still a handicraft practiced by many people. The present invention relate to a method of sewing by hand that is easier, faster, and more precise than conventional sewing methods. More specifically, the present invention relates to a method and system of sewing by hand comprising: (1) the use of a planar surfaces to spread and secure the fabric as necessary to achieve optimal visualization and stabilization of the fabric being worked on; (2) the use of an apparatus to support the planar surfaces and hold the fabric so that both hands are free for sewing; (3) the use of eyeless needless with pre-attached thread and sewing tools including pincers and needle holders, and (4) the use of both hands to accomplish precise and rapid sewing with ease.

[0051]According to a preferred embodiment, the handles of the sewing tools are ergonomic and the mechanisms are simple to facilitate sewing without having to train to use t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com