Froth handling pump

a technology of froth handling and froth pump, which is applied in the direction of priming pump, machine/engine, liquid fuel engine, etc., can solve the problems of reducing pump performance, affecting the performance of the pump, and affecting the flow and head of the pump, so as to achieve the effect of reducing or eliminating the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

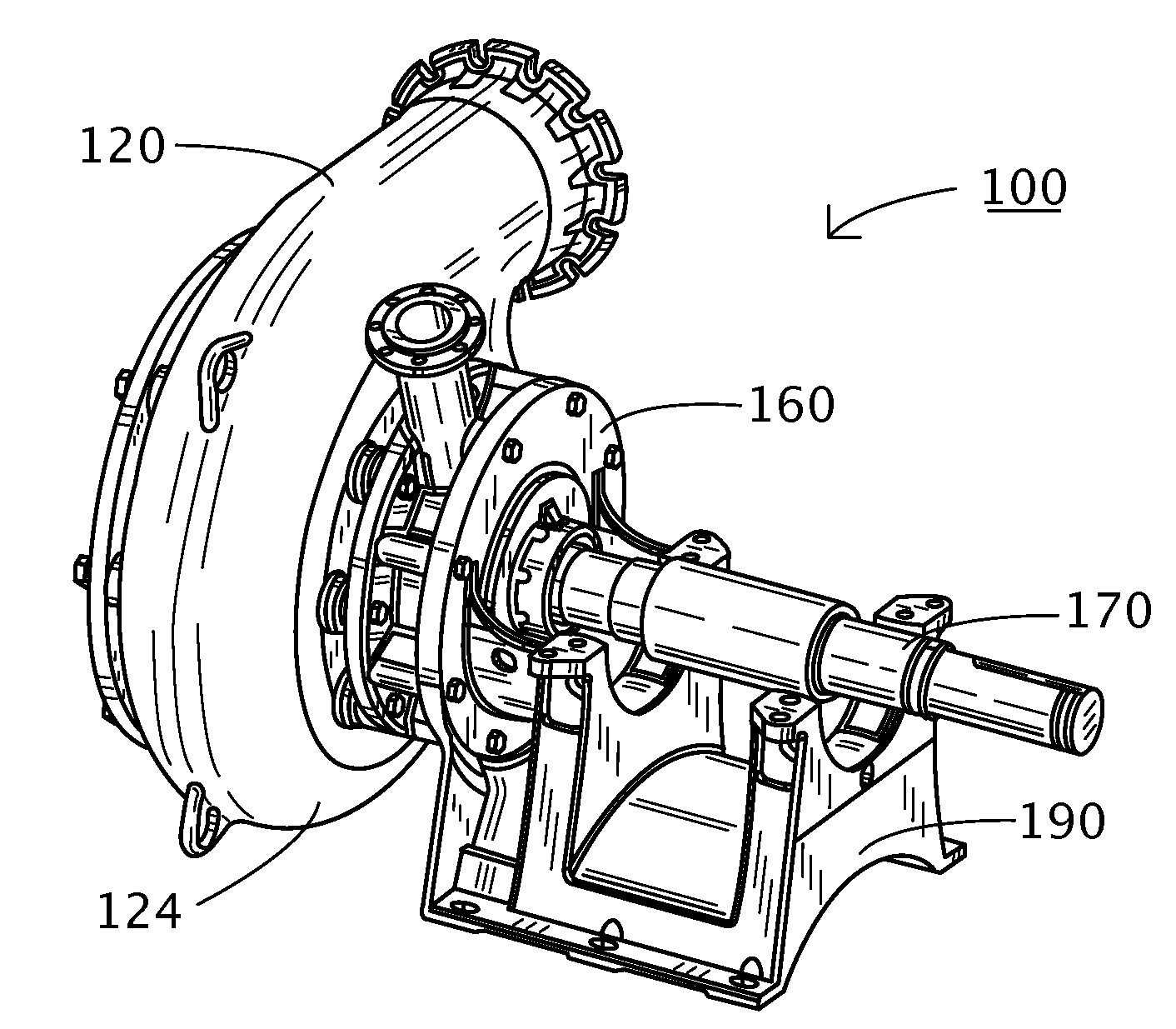

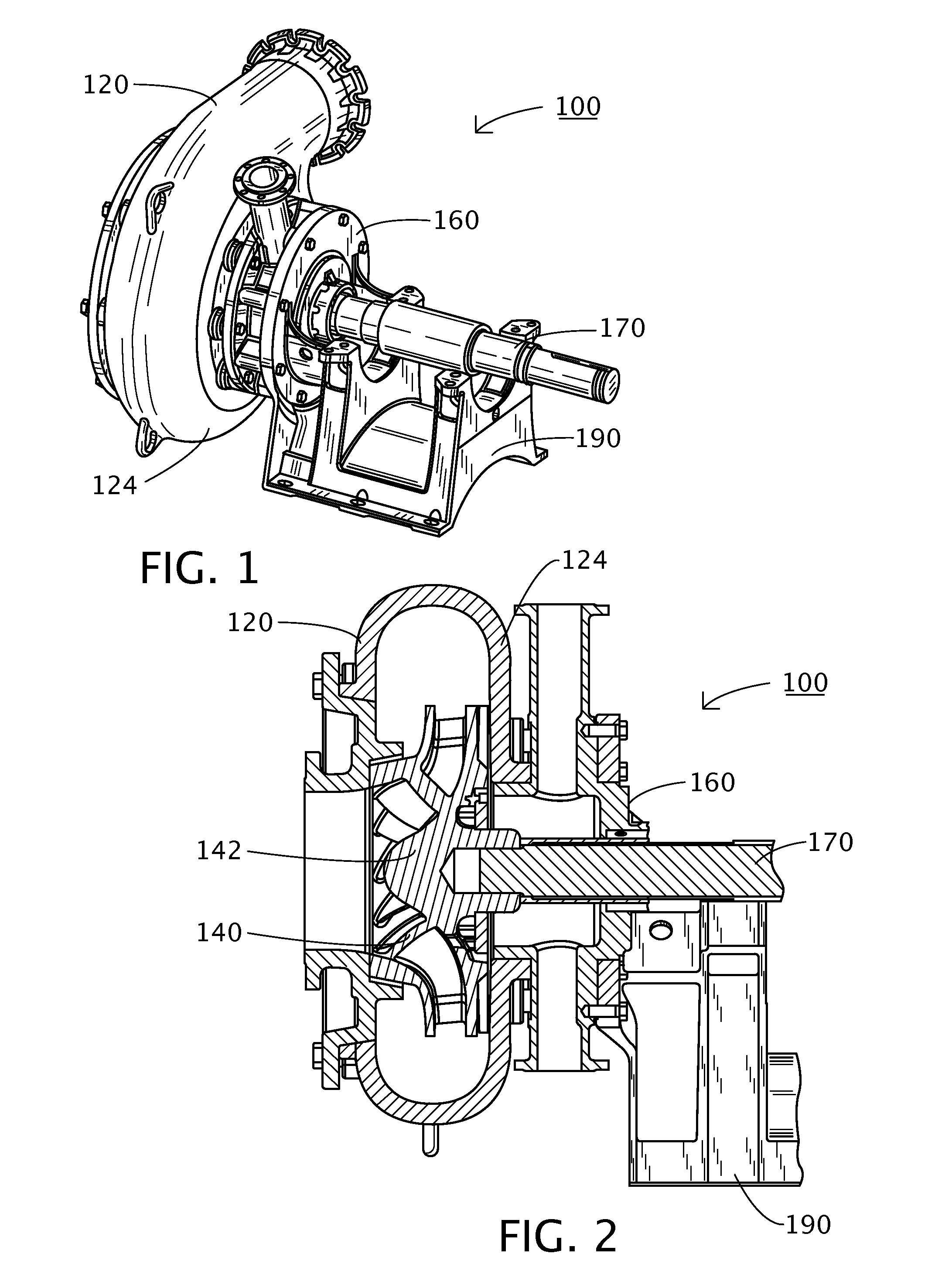

[0019]Referring to the Figures in general, and FIGS. 1 and 2 in particular, the froth handling pump of the present invention is shown generally as 100. In its simplest embodiment, the froth handling pump 100 comprises a centrifugal pump casing 120, a novel impeller 140 mounted in the casing, and a de-aeration chamber 160 mounted to the rear side 124 of the pump casing 120. A conventional pump shaft 170 passes through the de-aeration chamber 160 and attaches to the hub 142 of the impeller 140. The shaft 170 is then mounted on a conventional pedestal 190 via a conventional bearing arrangement (not shown).

[0020]As shown in FIG. 2, the pump casing 120 of the froth pump of the present invention is a conventional design for centrifugal slurry pumps; however, a modified, or more open inlet side may be contemplated for a particular froth handling application. Nonetheless, the froth handling pump 100 described herein eliminates the need for a casing or shroud modification.

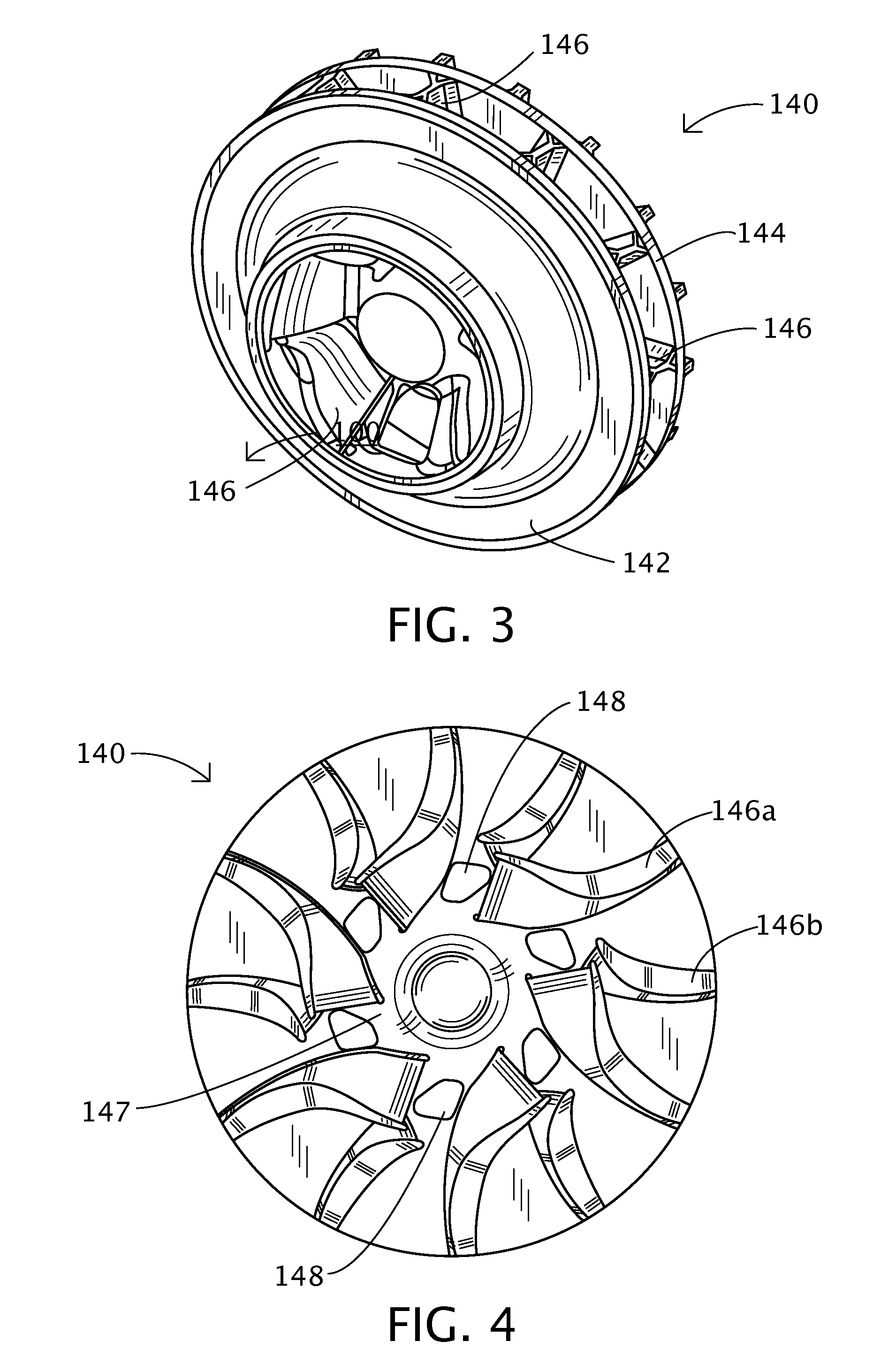

[0021]Referring to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com