Method of brewing different types of beverages with a single brewer

a brewer and a technology of brewing methods, applied in the field of brewing beverages, can solve the problems of not being able to quickly lower or raise the temperature, no operator accessible control to change the automatically maintained set temperature, and brewers are often disabled from performing another brewing cycl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

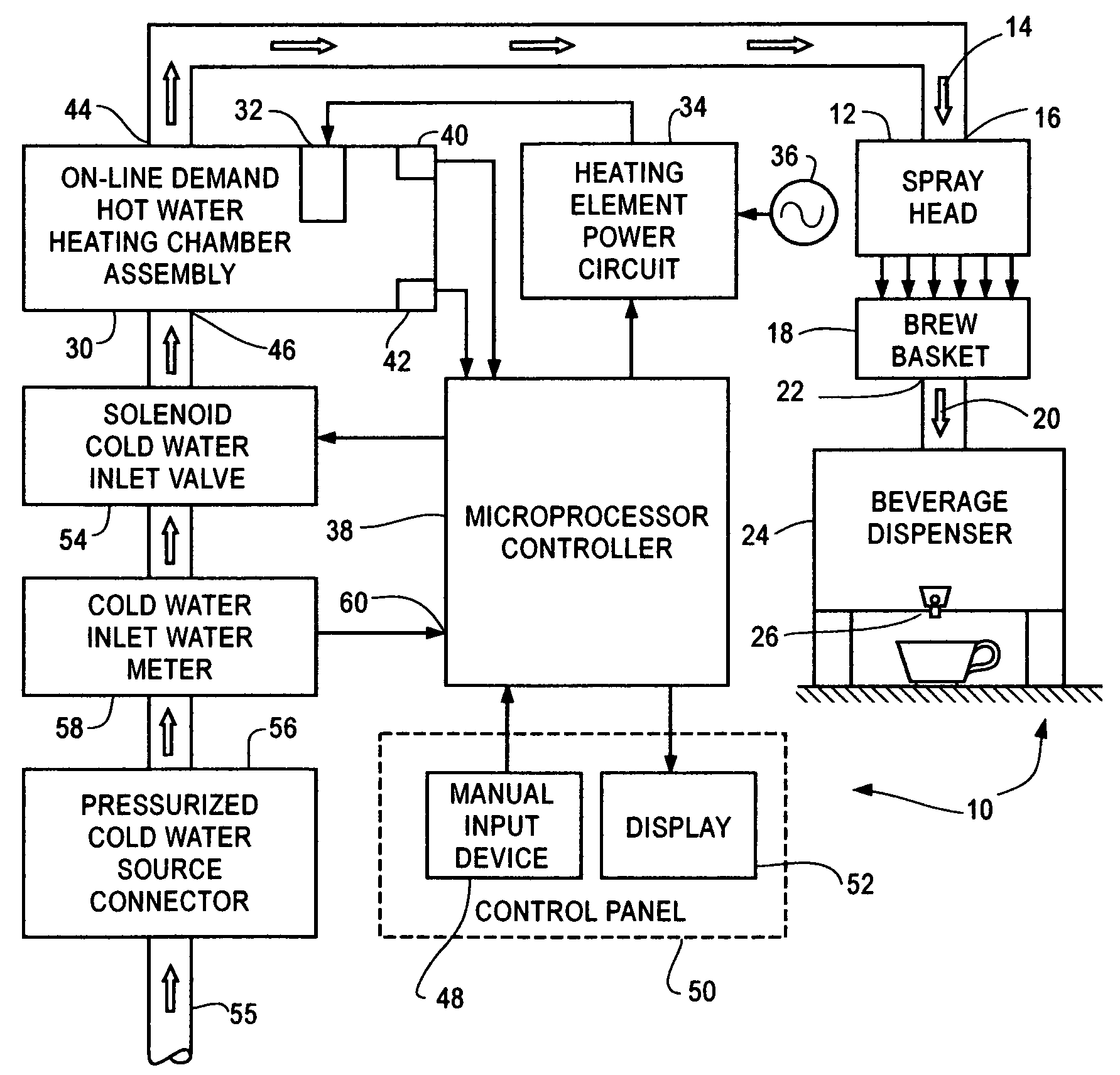

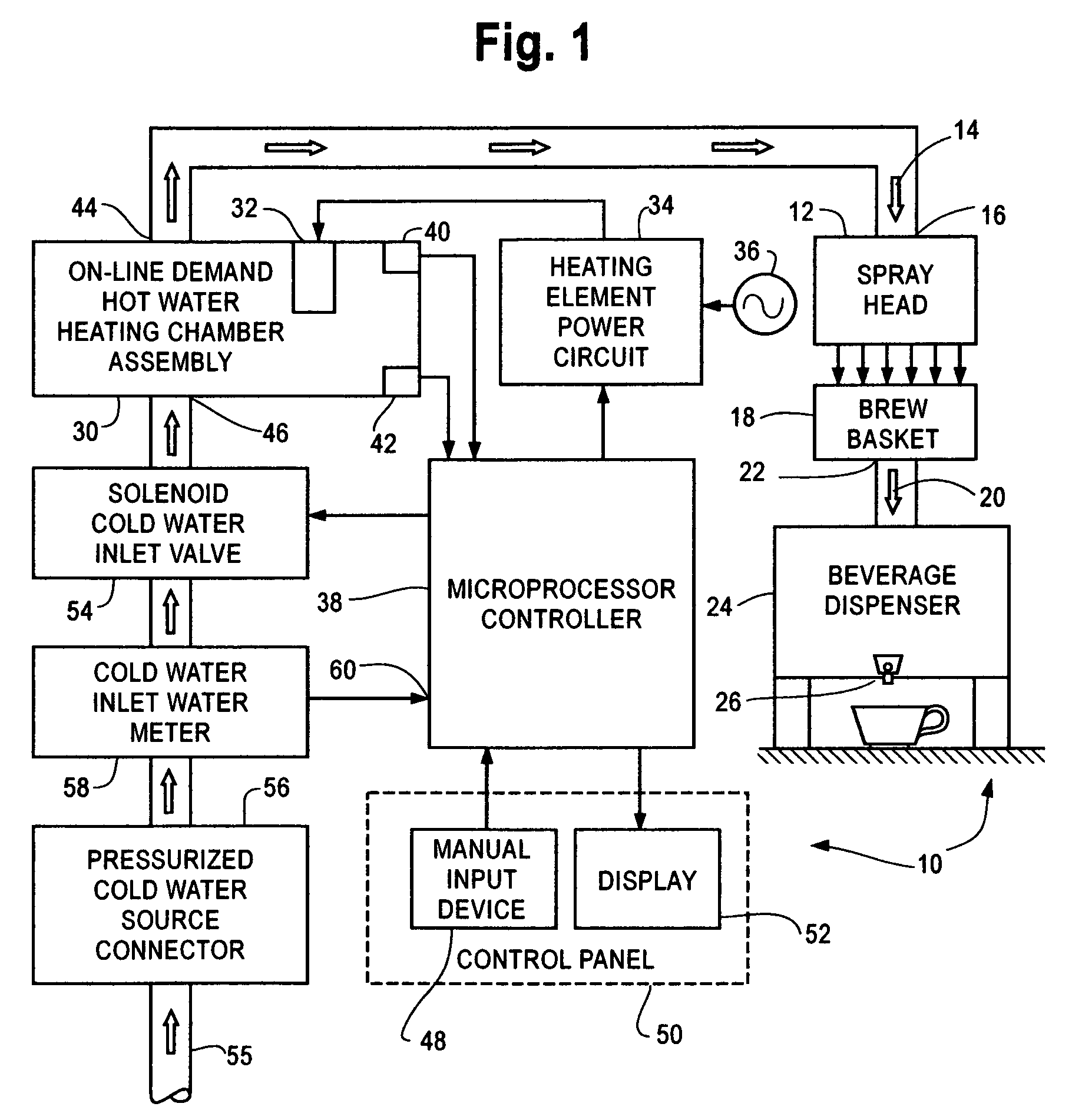

[0024]Referring now to FIG. 1, a preferred embodiment of the multi-brewer 10 of the present invention is seen to include a conventional spray head 12 that receives hot water, indicated by arrows 14, within a water input pipe 16, and sprays otherwise distributes the hot water through an open top of a brew basket 18. Contained within the brew basket is a container shaped wire filter basket (not shown) supporting a paper filter which, in turn, supports a layer of beverage ingredient, such a ground coffee beans, tea leaves, ground tea leaves, cocoa, etc. As the hot water percolates though the layer of beverage ingredient within the brew basket 18, beverage components dissolve and mix with the hot water to make the freshly brewed beverage. The freshly brewed hot beverage, indicated by arrow 20, such as freshly brewed coffee, passes through an outlet opening 22 in the bottom of the brew basket 18 and into an insulated beverage dispenser 24. The beverage dispenser 24 is portable, and after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com