Polarizing plate and method for producing the same

a technology of polarizing plate and polarizing element, which is applied in the field of polarizing plate, can solve the problems of affecting the image quality, the lowering of the optical properties in the environmental resistance test, and the impact of the liquid crystal display device to be used as an application of polarizing plate, and achieves excellent environmental resistance, good contrast, and satisfactory adhesiveness and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

(a) Preparation of Polarizer

[0118]A polyvinyl alcohol film having a thickness of 120 μm was dipped in an aqueous solution containing 1 part of iodine, 2 parts of potassium iodide and 4 parts of boric acid and stretched 4 times at 50° C., thereby obtaining a polarizer. On one surface of the obtained polarizer, a PVA based adhesive was coated, on the surface of which was then stuck a triacetyl cellulose film having been subjected to a saponification treatment and having a thickness of 50 μm. The obtained polarizer film is named a TAC-less film.

(b) Preparation of Protective (Retardation) Film

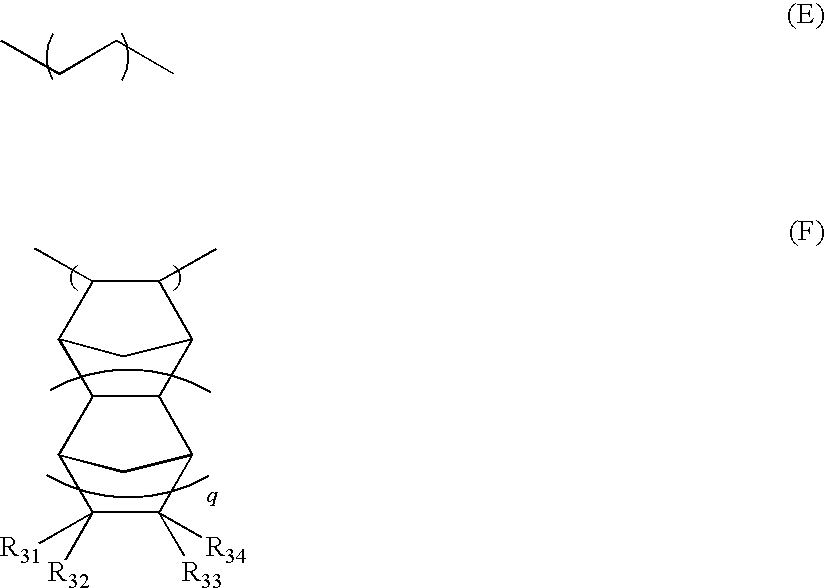

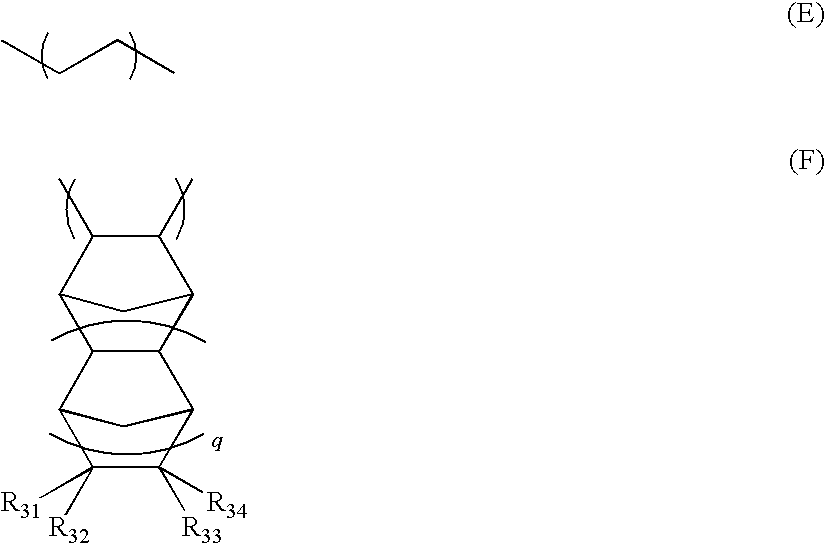

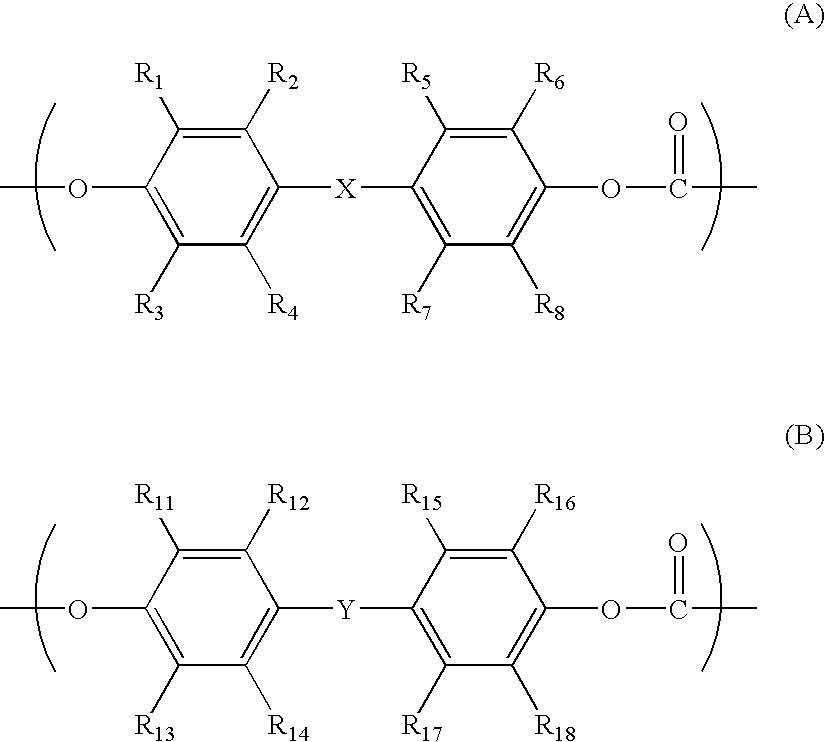

[0119]In a reaction tank equipped with a stirrer, a thermometer and a reflux condenser, a sodium hydroxide aqueous solution and ion exchanged water were charged, the monomers (C) and (D) having the foregoing structures in a molar ratio of 85 / 15 were then dissolved therein, and a small amount of a hydrosulfite was further added. Next, methylene chloride was added thereto, and phosgene was blown at 2...

example 2

[0125]A polarizing plate was obtained in the same manner as in Example 1, except that the polyurethane-containing adhesive was prepared by blending 100 parts of “ADW-615” (polyether polyurethane; an aqueous solution having a solids content of 40%), manufactured by Toyo-Morton, Ltd. with 11.1 parts of “CATRT-34” (goods having 100% of an active component), manufactured by Toyo-Morton, Ltd., which is an isocyanate based curing agent.

[0126]As to the obtained polarizing plate, peeling of the evaluation of adhesiveness was tried to achieve. However, the polarizing plate was broken on the way of peeling, and the adhesiveness was thus good. The degree of polarization was 99.8% so that the polarizing plate was confirmed to have sufficient properties as a polarizing plate. Also, in the environmental resistance test in a dry environment at 80° C. and an environment at 60° C. and 900 RH, respectively for 1,000 hours, good results were obtained in all of the change in degree of polarization, the...

example 3

[0128]A polarizing plate was obtained in the same manner as in Example 1, except that the polyurethane-containing adhesive was prepared by blending 100 parts of “ADW-615” (polyether polyurethane; an aqueous solution having a solids content of 40%), manufactured by Toyo-Morton, Ltd. with 11.1 parts of “TDW4575B” (goods having 100% of an active component), manufactured by Toyo-Morton, Ltd., which is an isocyanate based curing agent.

[0129]As to the obtained polarizing plate, peeling of the evaluation of adhesiveness was tried to achieve. However, the polarizing plate was broken on the way of peeling, and the adhesiveness was thus good. The degree of polarization was 99.8% so that the polarizing plate was confirmed to have sufficient properties as a polarizing plate. Also, in the environmental resistance test in a dry environment at 80° C. and an environment at 60° C. and 90% RH, respectively for 1,000 hours, good results were obtained in all of the change in degree of polarization, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com