[0006]According to the invention, an aid for pulling off elastic stockings comprises a flexible, tube-like

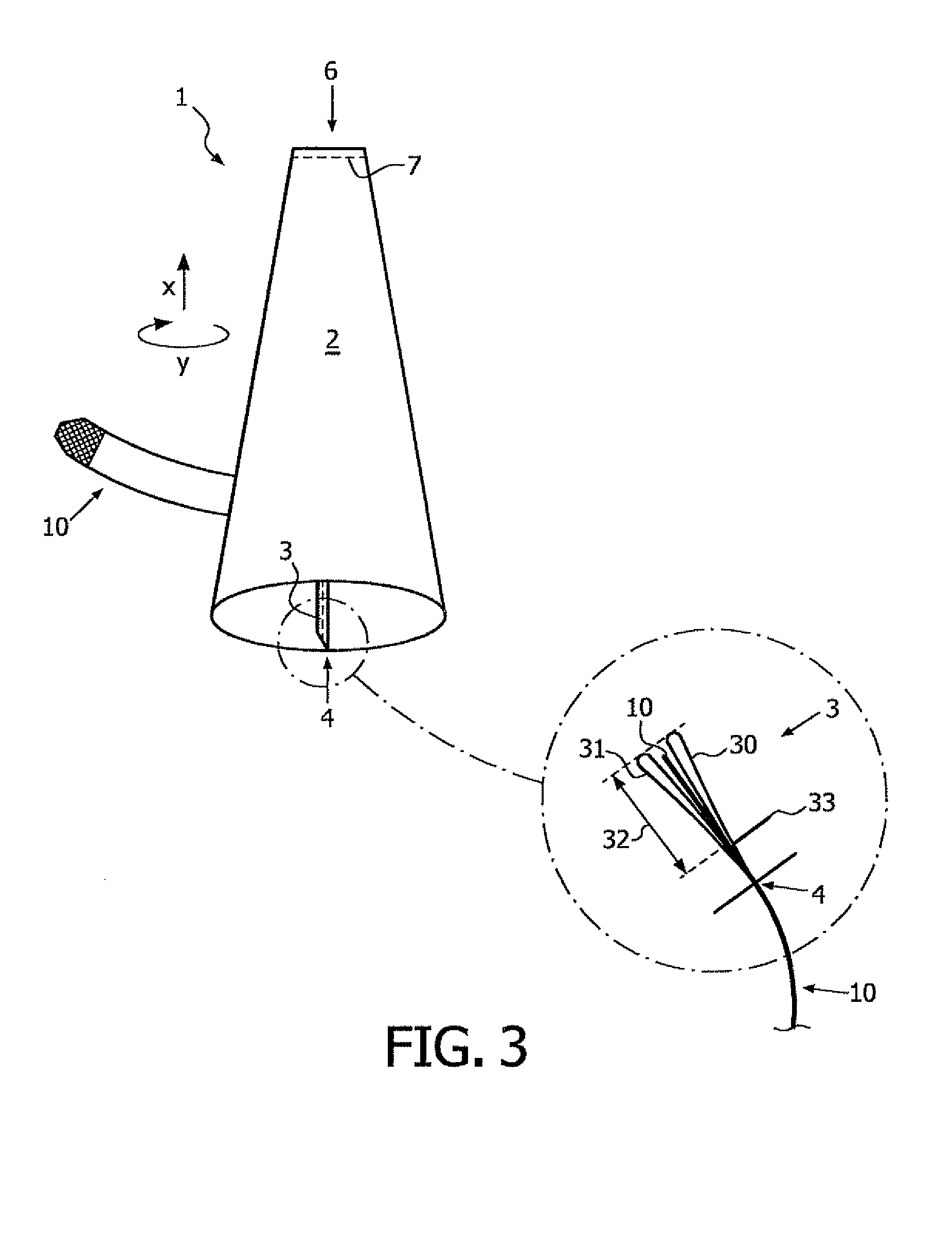

peripheral body of a smooth material, which in use can be slid round a leg provided with an elastic stocking, wherein the peripheral body is provided on its side remote from the leg with fixation means with which the aid can be arranged at least temporarily round the leg. This achieves that pulling off an elastic stocking can take place without exerting considerable force. In order to enable an elastic stocking to be taken off, the foot is first placed into the opening of the aid and the aid arranged round the leg provided with the elastic stocking. The aid is subsequently fitted round the leg, or lower leg, using fixation means. The upper edges of the elastic stocking and the aid are then jointly grasped and folded back a small distance in the direction of the foot, such that the folded part of the peripheral body of the aid makes contact with a non-folded part of the same peripheral body. By now further unrolling the elastic stocking by hand in the direction of the foot, the parts of the peripheral body of the aid will slide over each other. Although both parts of the peripheral body will be held against each other under the pressure of the elastic stocking, the sliding can take place practically without friction, among other reasons due to the properties of the material from which the aid is manufactured. The part of the elastic stocking that is in contact with the leg, which contact could in principle cause quite a high

friction force, substantially remains stationary. The fixation means ensure among other things that the aid and the stocking do not slide prematurely from the foot during unrolling of the elastic stocking. During further combined unrolling of stocking and aid in the direction of the foot, the fixation means will at a given moment be reached. In order to enable complete unrolling of the stocking, the fixation by these fixation means has to be ended. This can be done by hand, but preferably takes place automatically. This latter preferred option will be further described below. After the elastic stocking has thus been removed from the leg, the aid is in inside-out position inside the elastic stocking. The aid can be removed easily from the stocking and restored to its original form for re-use by once again turning the aid inside-out.

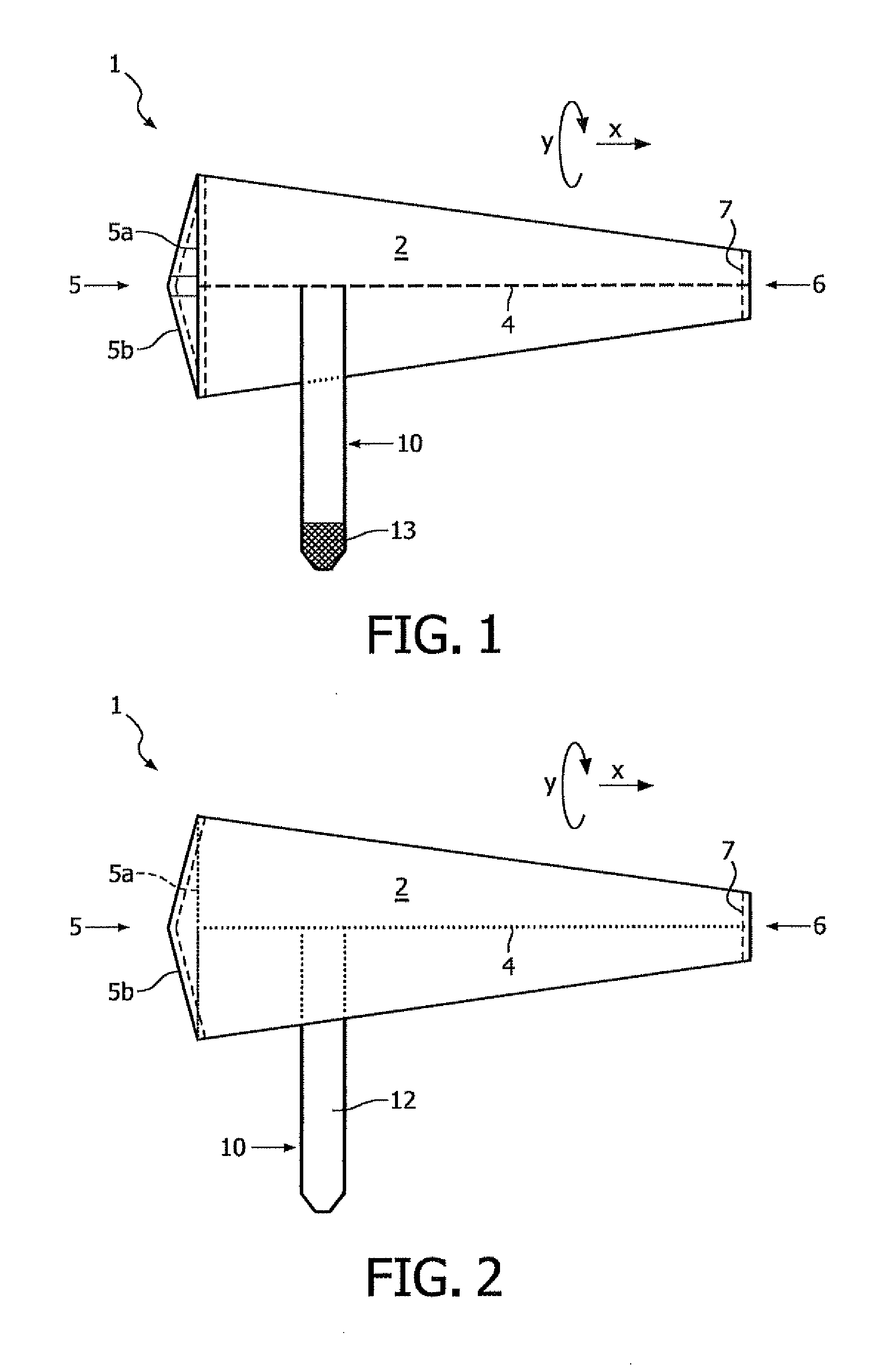

[0007]In a preferred embodiment the aid according to the invention is characterized in that the fixation means comprise an elastic band which can be arranged round the leg in peripheral direction and which is further provided with closing means, with which the band can be secured at least temporarily onto itself. After the aid has been arranged round the leg at the desired height, the free ends of the elastic band according to the invention is grasped and trained round the leg in peripheral direction and secured to itself using the closing means. Because the band is elastic, the band can be arranged with a certain tension round the leg. This ensures that, in any case at the height of the position of the band, the aid will be held relatively tightly against the leg. The aid can be held more loosely against the leg at other positions, if desired. The aid can be in principle be arranged at any desired height. Preferably however, the aid is arranged at a height extending to just below the level of the elastic stocking. Because the elastic stocking is thus left free on the upper side thereof, it can easily be grasped and folded back over only a small height. The fixation means can in principle also be arranged at any desired height. The fixation means are preferably arranged at the height of the lower leg. A further

advantage of the aid according to the invention is that during unrolling of the elastic stocking the fixation means are hidden under the stocking, and are thus not accessible to the user. This prevents the user performing undesirable actions with the fixation means during unrolling of the stocking.

[0009]It is advantageous if the elastic band is provided on one side with primary Velcro strip and on the other side with secondary Velcro strip, wherein the secondary Velcro strip still more preferably extends along a relatively small part of the free outer end of the band. Secondary Velcro tape has a rougher surface than primary Velcro tape and can therefore more easily cause damage to the elastic stocking. By limiting the surface area of the secondary Velcro tape according to the present preferred variant, the risk of damage is decreased.

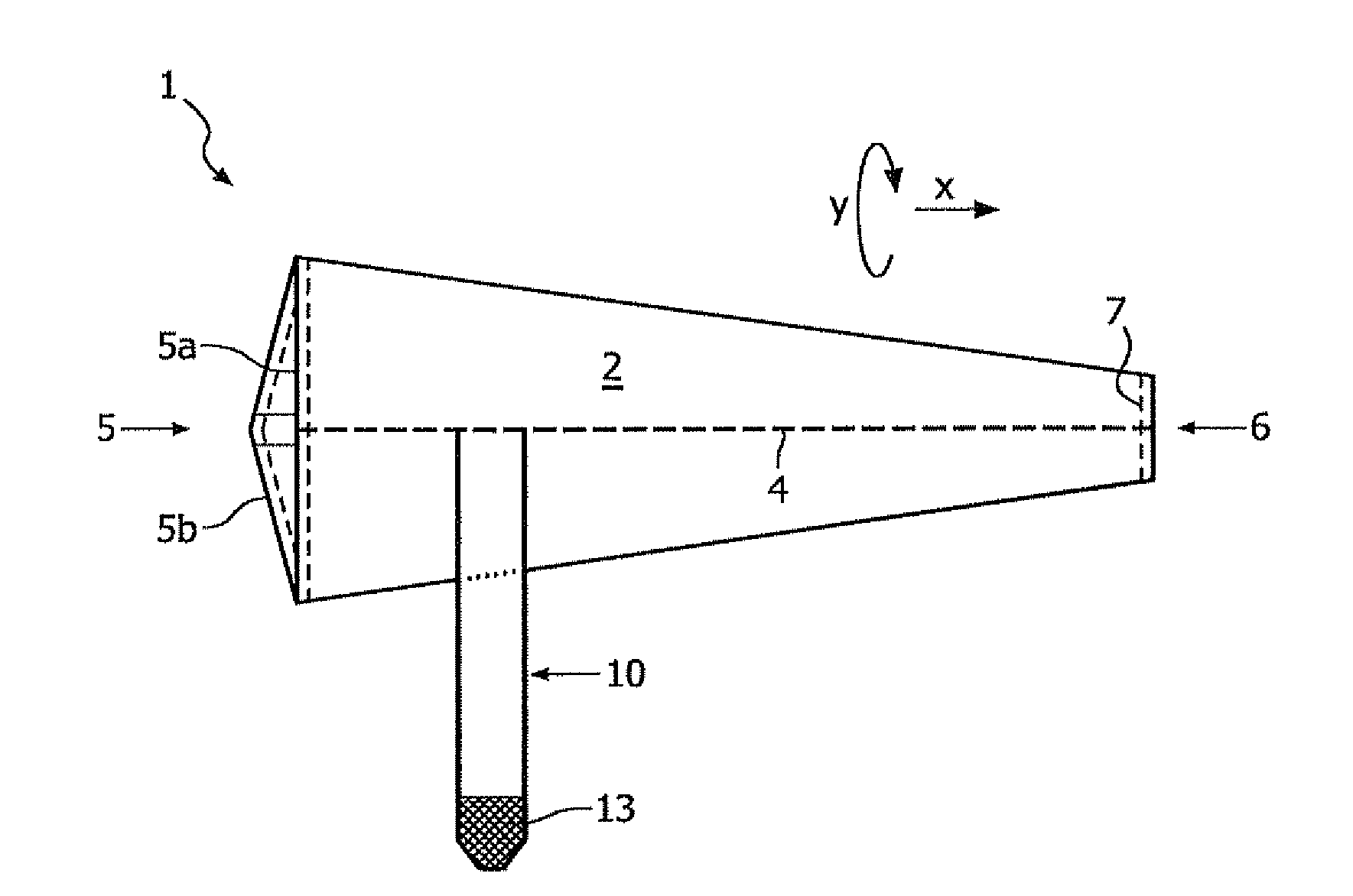

[0010]The aid can in principle be manufactured in any way. According to a preferred variant, the aid is characterized in that the peripheral body is formed by bringing together and at least partially connecting to each other two opposite

free edge portions of a flat sheet of the material, thereby forming a shared edge portion. This makes arranging of the aid easier and results in improved functionality thereof. How the fixation is performed does not matter here. It is thus possible to connect both

free edge portions by means of a ‘permanent’ connection, such as for instance a stitch connection and / or an

adhesive connection. Another option consists of connecting the two sheets to each other by means of a releasable connection, such as for instance with Velcro tape. If desired, both edge portions can then be connected to each other only when in use.

[0011]The shared edge portions preferably extend in longitudinal direction of the aid and the fixation means are attached to the shared edge portions. It is further advantageous if the connection is a stitched connection, which is formed by a felled seam. A further reduced friction between aid and contact surface can be achieved by arranging the connection in the form of a felled seam. It has moreover been found that the use of a felled seam prolongs the lifespan of the aid without this having adverse effects on the operation thereof.

[0014]The material from which the

textile structure is manufactured can also be selected within wide limits. Suitable materials comprise glass fibers,

carbon fibers, organic fibers such as for instance polyaramid fibers,

polyethylene fibers,

polyamide fibers,

polyester fibers and so on. A particularly suitable aid comprises a

textile structure manufactured from a plastic selected from the group of polyesters and / or polyamides. The

frictional resistance of the materials moving against each other during the “unrolling” can further be reduced by using a

thermoplastic plastic and / or low-friction plastic to which an anti-block agent such as for instance

hydrotalcite has been added. The above stated materials have a very low

coefficient of friction, are generally highly anti-

adhesive and moreover weather and

sunlight-resistant. The materials are further sufficiently strong to withstand, with negligible elongation, the tensile stresses occurring while pulling off elastic stockings.

Login to View More

Login to View More  Login to View More

Login to View More