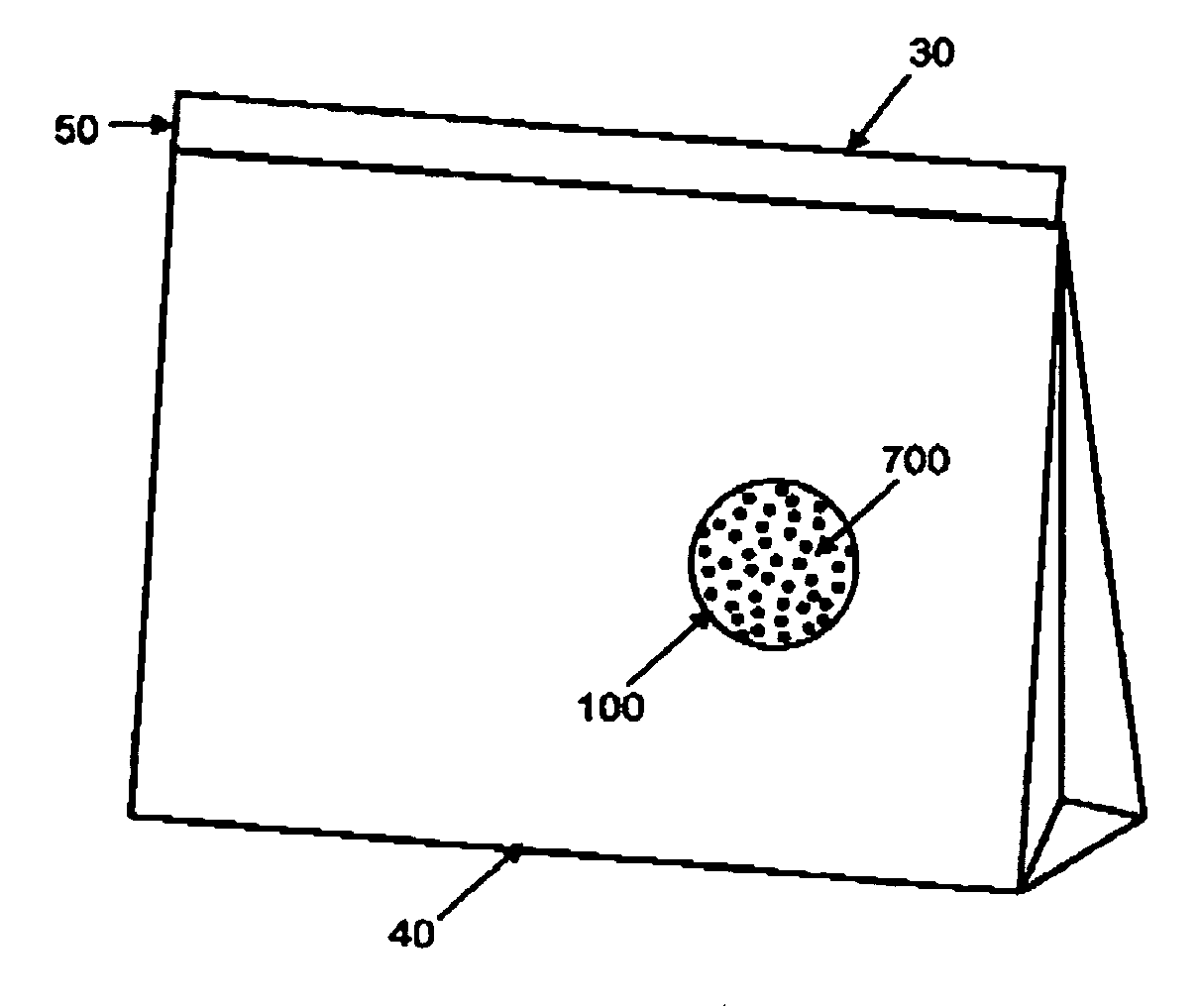

Package for granular compositions

a technology of granular compositions and packaging, applied in the direction of packaging goods, liquid materials, transportation and packaging, etc., can solve the problems of product leaking out of the bag, package to appear dirty and/or greasy and undesirable, and product sifting can occur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

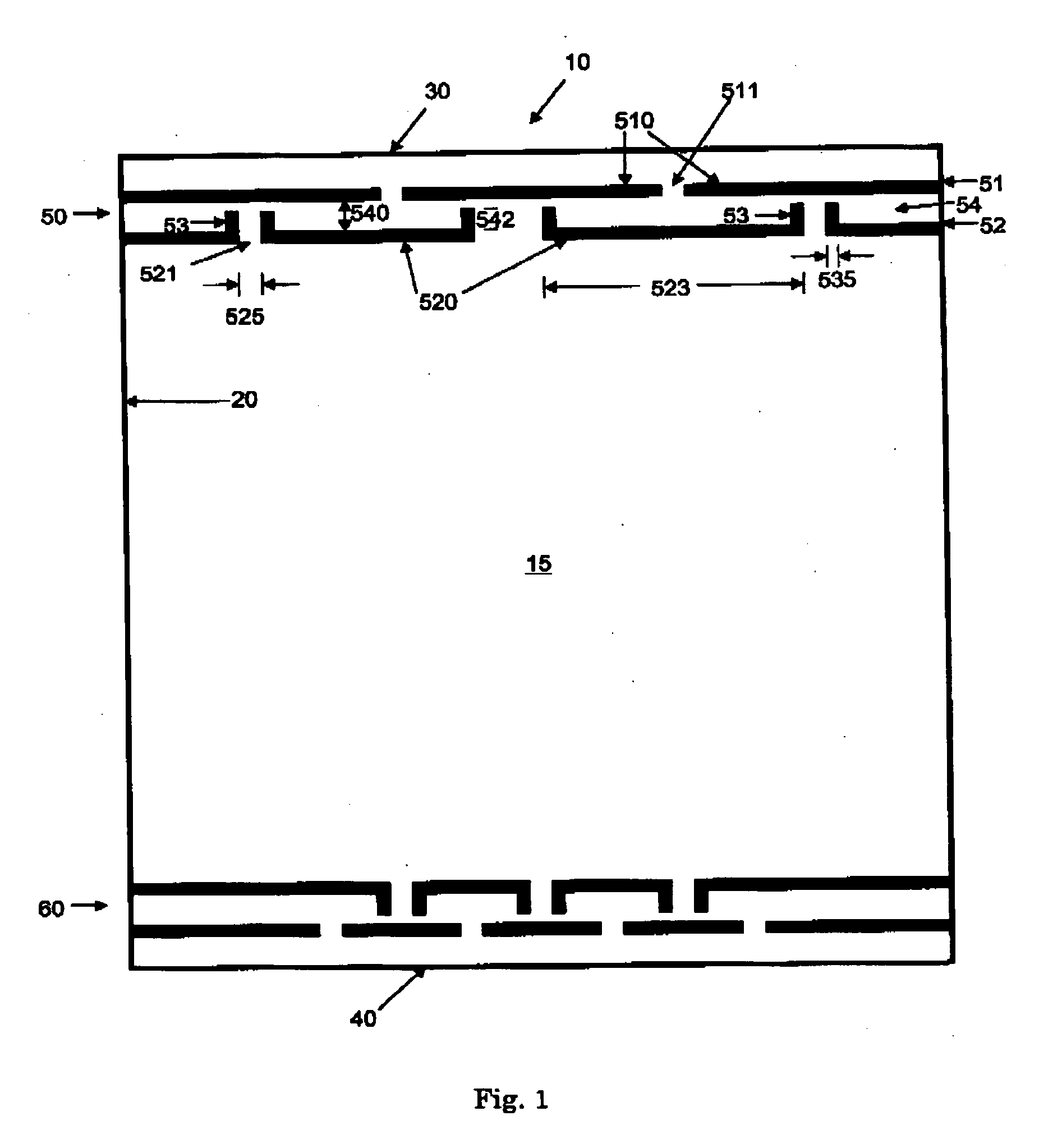

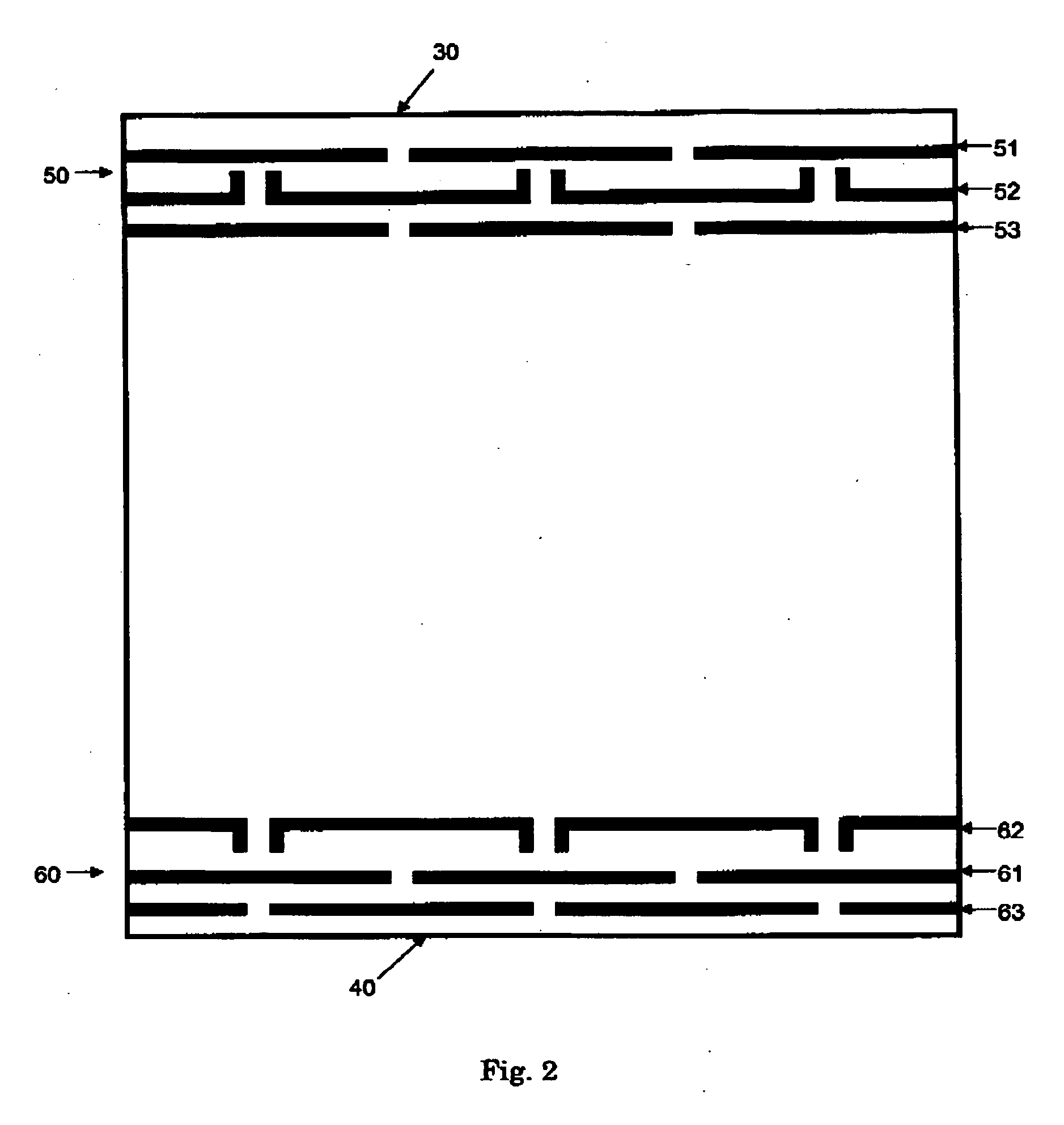

[0024]The present invention comprises a package for storing granular of powdered compositions capable of providing sufficient air venting capabilities meanwhile controlling product sifting occurrence. It has importantly been found that the packages in accordance with the present invention provides for sufficient air venting capabilities to allow any excess air to escape at a sufficient rate to allow for the package to sufficiently deflate after being filled with product. It has further been found that the package in accordance with the present invention controls the occurrence of undesired product sifting while achieving the sufficient air venting capabilities. Without intending to be bound by theory, it is believed that as air venting capabilities increase, product sifting occurrences also increase because the increase ability to vent air tends to allow increased product to escape. It has further been found that the present invention is capable of providing the sufficient air venti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com