Rubber Composition For Adhering Steel Cord

a technology of steel cords and compositions, applied in the direction of yarn, transportation and packaging, synthetic resin layered products, etc., can solve the problems of large decrease in adhesioness, layer failure, and performance recently required cannot be satisfied, so as to improve wet heat-resistant adhesioness, improve initial adhesioness, and improve heat-resistant adhesioness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

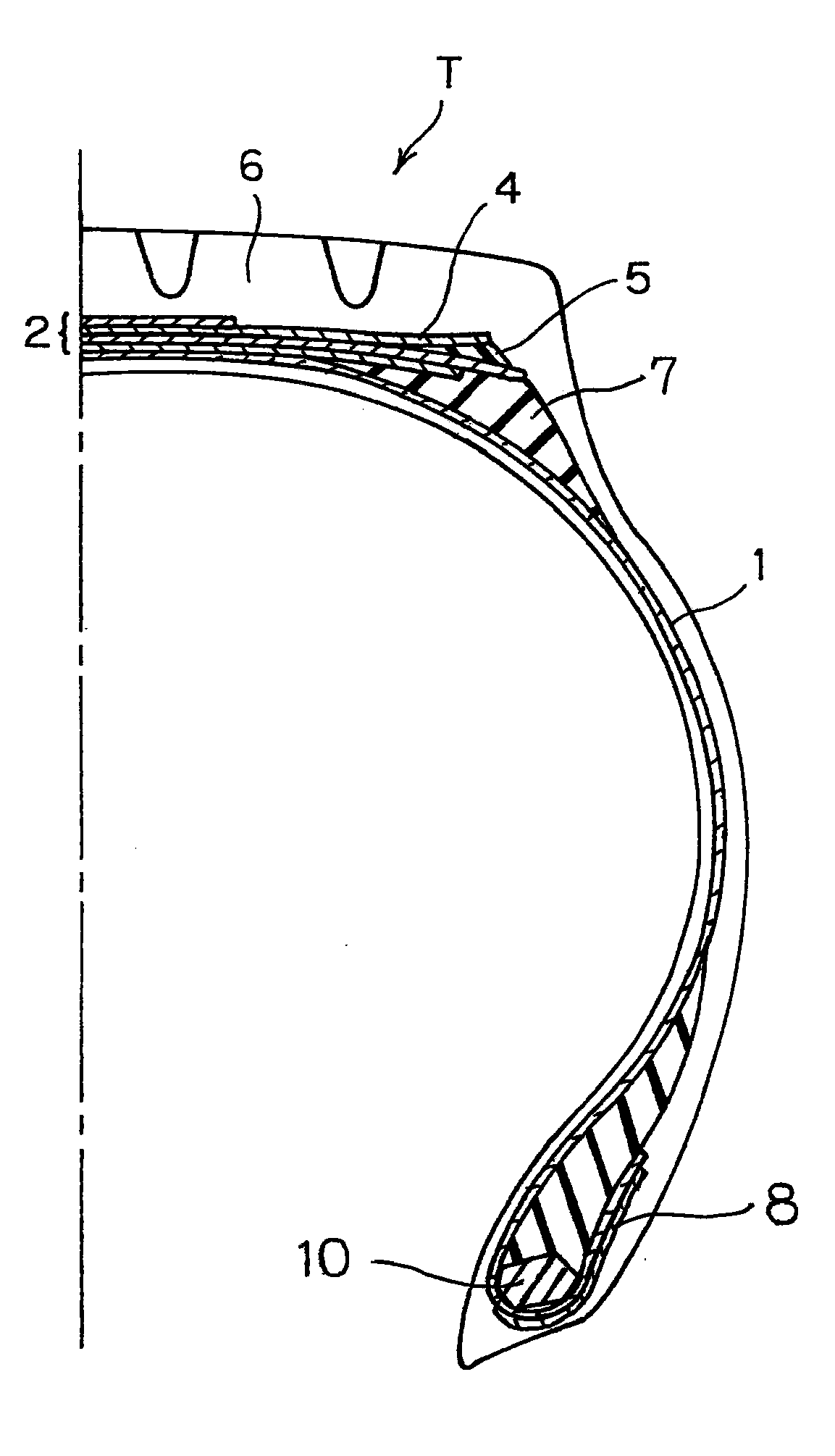

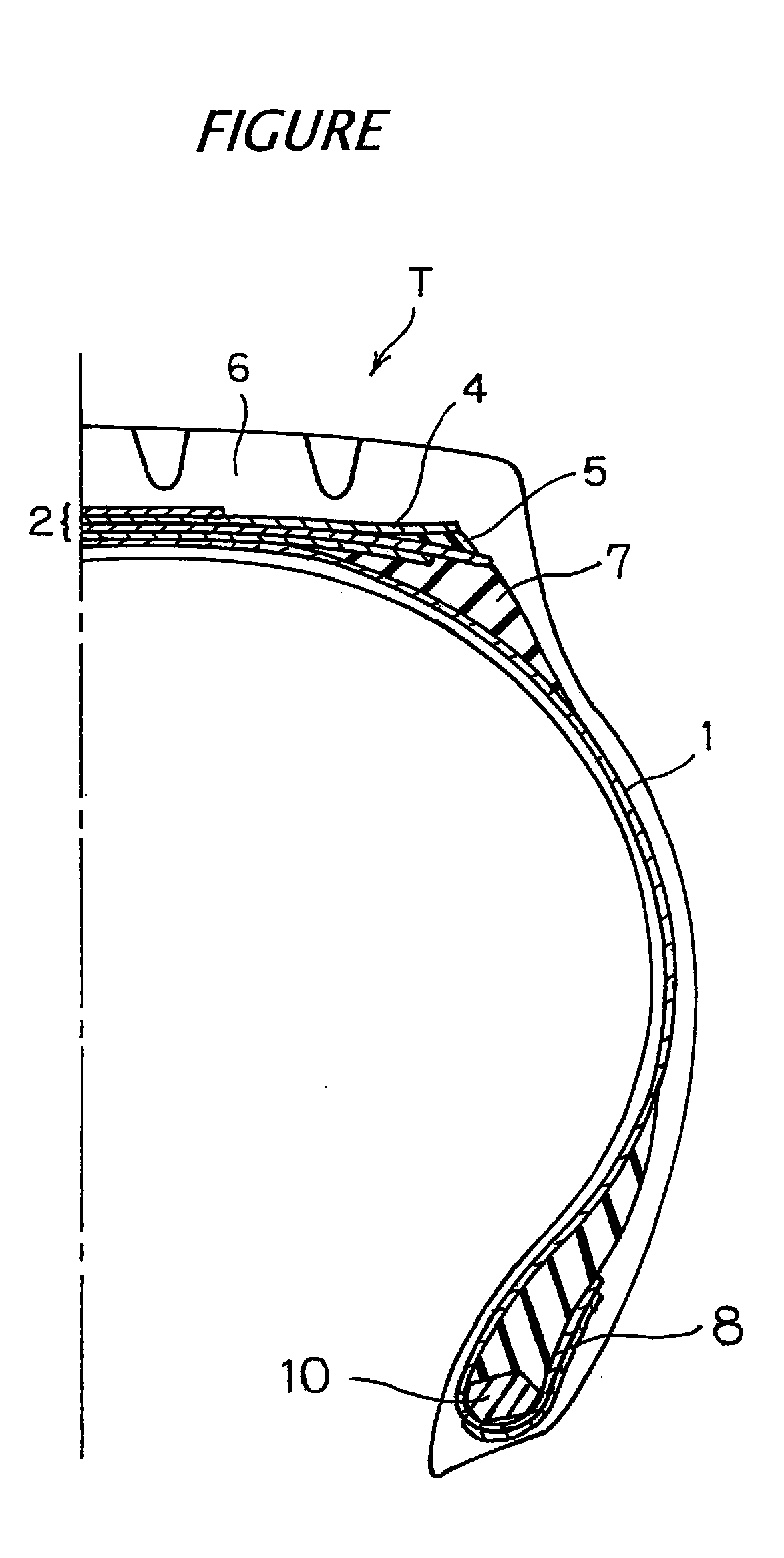

Image

Examples

examples

[0044]The present invention is specifically described below based on the Examples, but the invention is not construed as being limited thereto.

[0045]Carbon black, composite graphite particles and boron-containing organic acid cobalt shown below in the compounding amounts (parts by weight) shown in the Table 1, and the common formulation components (parts by weight) shown below were compounded with 100 parts by weight of a natural rubber (RSS#3, made in Thailand), and the resulting mixtures each were kneaded using a sealed Banbury mixer having a volume of 20 liters to prepare rubber compositions of Examples and Comparative Examples.

Carbon Black, Composite Graphite Particles, and Boron-Containing Organic Acid Cobalt

[0046]Carbon black HAF: SHOWBLACK N326, manufactured by Showa Cabot K.K.

[0047]Carbon black SAF: SEAST 9, manufactured by Tokai Carbon Co., Ltd.

[0048]Composite graphite particle BH110: BH110, manufactured by Nippon Steel Chemical Carbon Co., Ltd., carbide of boron (B4C):carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com