Stent and Method For Fabricating the Same

a technology of stent and stent body, which is applied in the field of stent, can solve the problems of repeated stenosis and high probability of restenosis, and achieve the effect of preventing restenosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

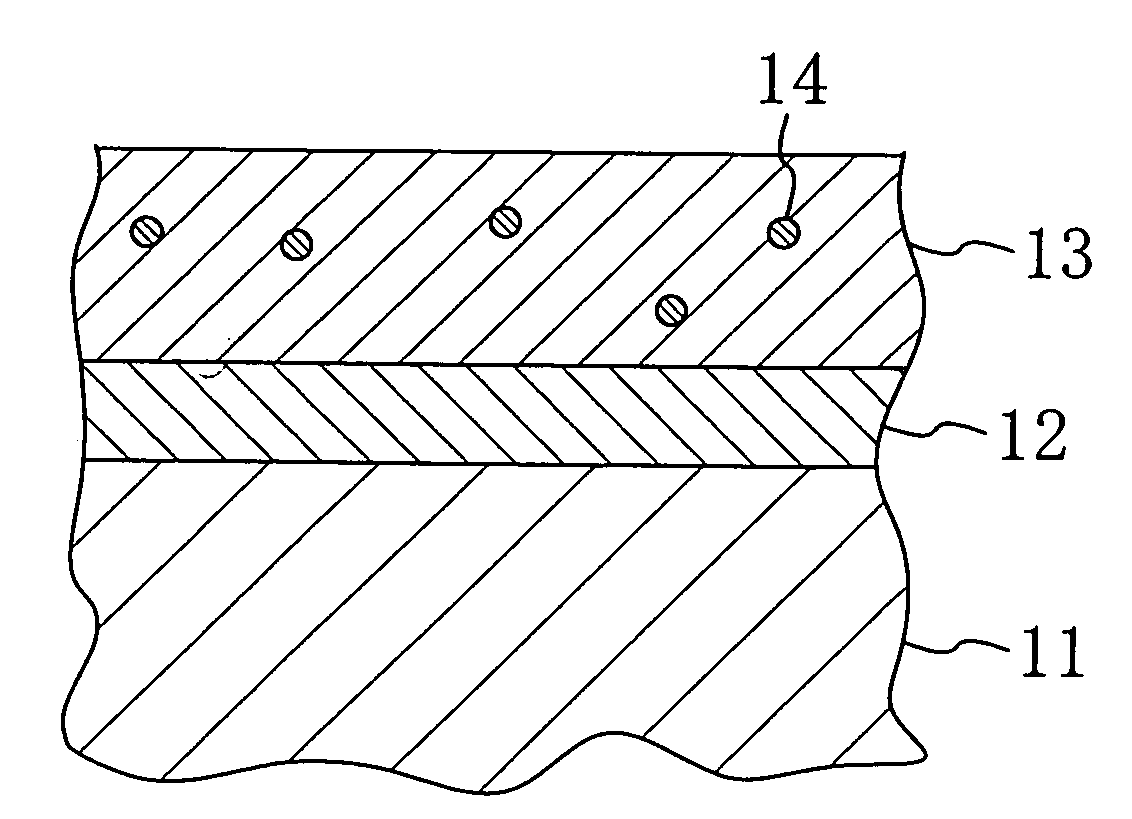

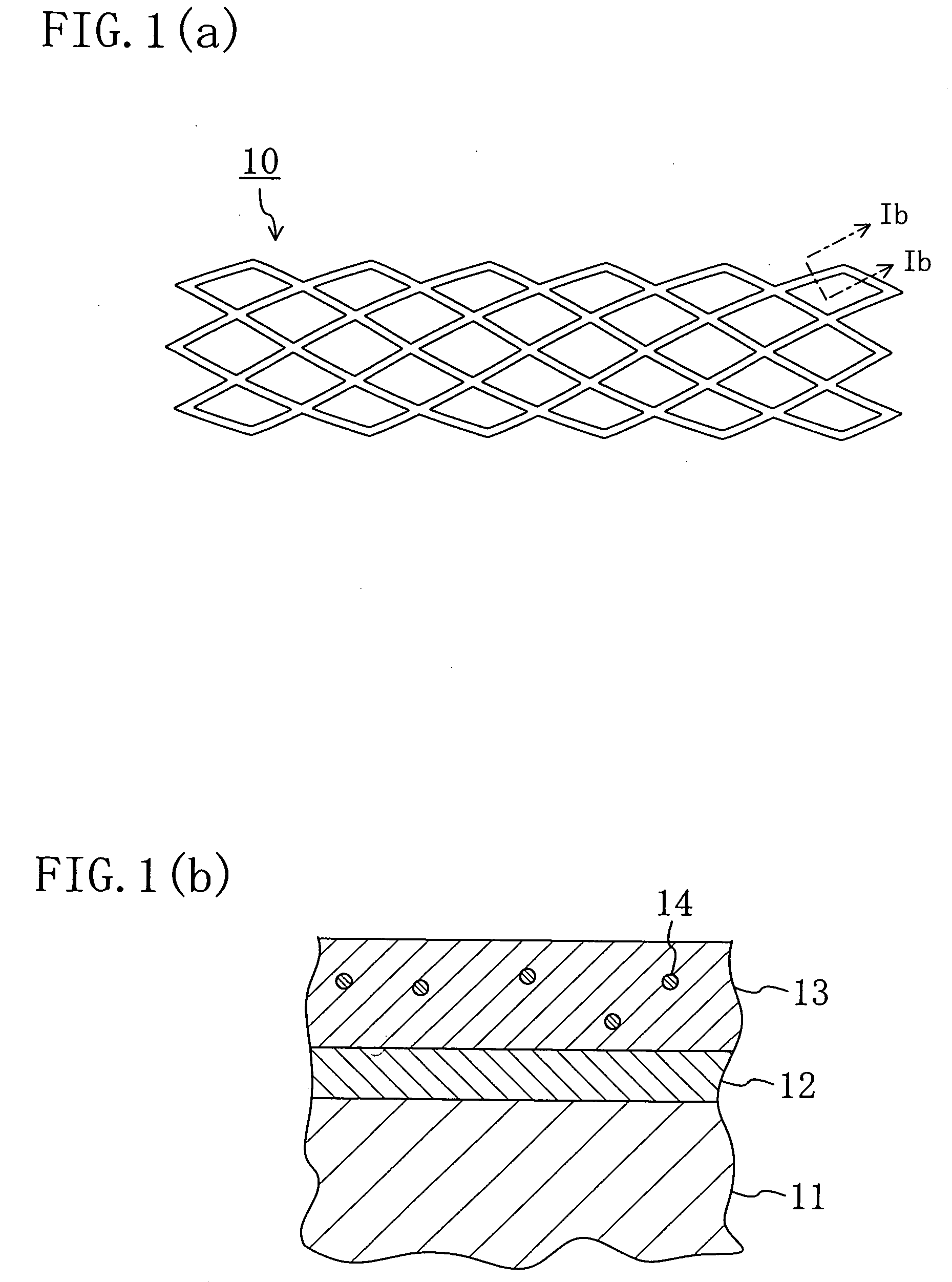

[0105]The stent of the present invention will now be described in detail by describing a specific example. In this example, a Co—Cr alloy stent having a length of 19 mm, a diameter of 1.5 mm and a cell thickness of 75 μm was used as the stent body 11.

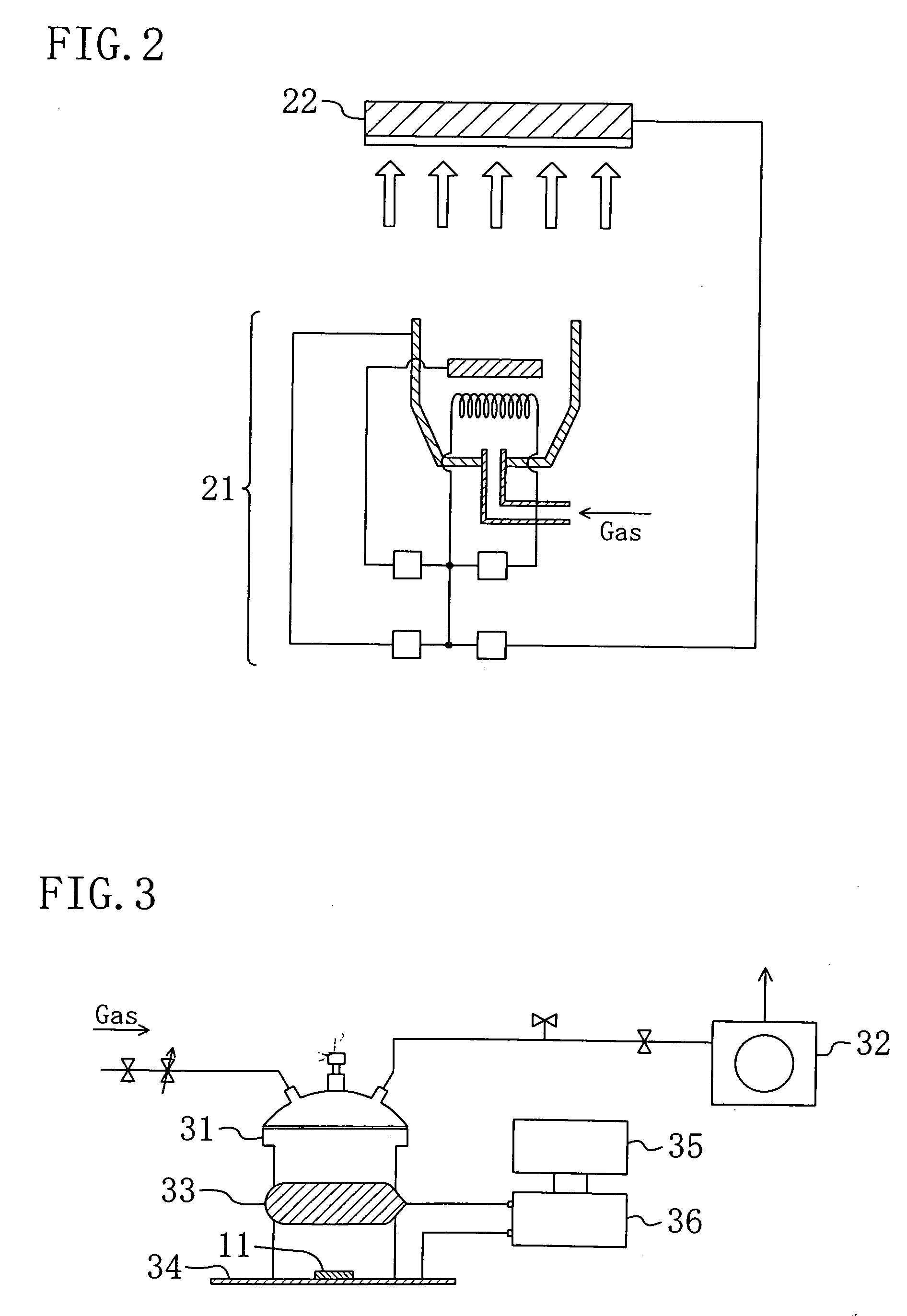

[0106]FIG. 2 schematically shows an ionization evaporation system used in this example, and this is a general ionization evaporation system in which a DLC film is solidified and deposited on a target 22 by colliding, against the target 22 biased to a negative voltage, plasma generated by introducing Ar and benzene (C6H6) gases corresponding to ion sources into a DC arc discharge plasma generator 21 provided within a vacuum chamber.

[0107]A stent body 11 was set within the chamber of the ionization evaporation system of FIG. 2, and bombardment cleaning, in which Ar ions are produced by discharging after introducing an argon gas (Ar) into the chamber so as to attain a pressure of 10−1 Pa through 10−3 Pa (10−3 Torr through 10−5 Torr) and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com