Method and apparatus for improving the performance of suction powered pool cleaning systems

a technology of pool cleaning and suction power, which is applied in the direction of swimming pools, chemistry apparatus and processes, water/sludge/sewage treatment, etc., can solve the problems of increasing the likelihood of cavitation, increasing the magnitude of negative pressure, and insufficient water flow from the cleaner alone to satisfy the pump flow requirements. , to achieve the effect of reducing preventing cavitation, and increasing the capacity of pump flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

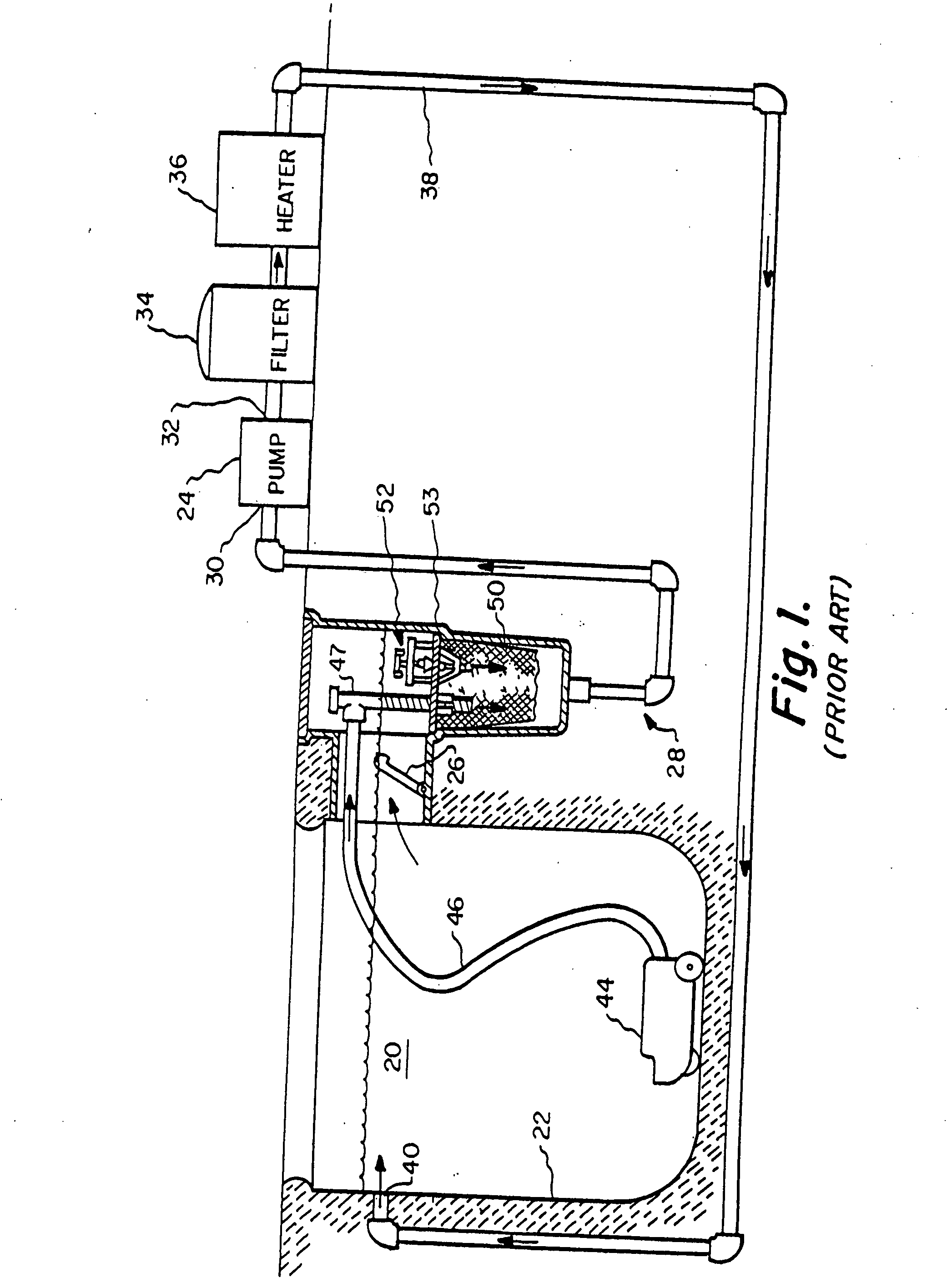

[0020]Attention is initially directed to FIG. 1 which diagrammatically depicts an exemplary conventional system for cleaning the water in pool 20 (i.e., filtering mode) as well as cleaning the surface of wall 22 (including bottom and side portions) containing the pool (i.e., cleaning mode). Water cleaning, i.e., filtering, is accomplished primarily by causing pump 24 to pull pool water 20 through skimmer and or drain 26 (“skimmer / drain”) through suction side plumbing 28 to the pump suction inlet 30. The pump pressure outlet 32 returns the water to the pool via a filter 34, and optionally a heater 36 and / or chlorinater via pressure side plumbing 38 to one or more return outlets 40.

[0021]Wall cleaning is primarily achieved by operating an automatic traveling pool cleaner 44 which is coupled via a flexible suction hose 46 and plumbing 28 to the pump suction inlet 30. The suction, i.e., negative pressure, provided by the pump 24 to the cleaner 44, powers the cleaner primarily to (1) pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com