Non-destructive testing and imaging

a technology of non-destructive testing and imaging, applied in the direction of vehicle tyre testing, structural/machine measurement, instruments, etc., can solve the problems of high-sensitivity film output, high cost, and special viewing devices, and the cost of individual tire testing and film based shearographic tire testing machines are typically very high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

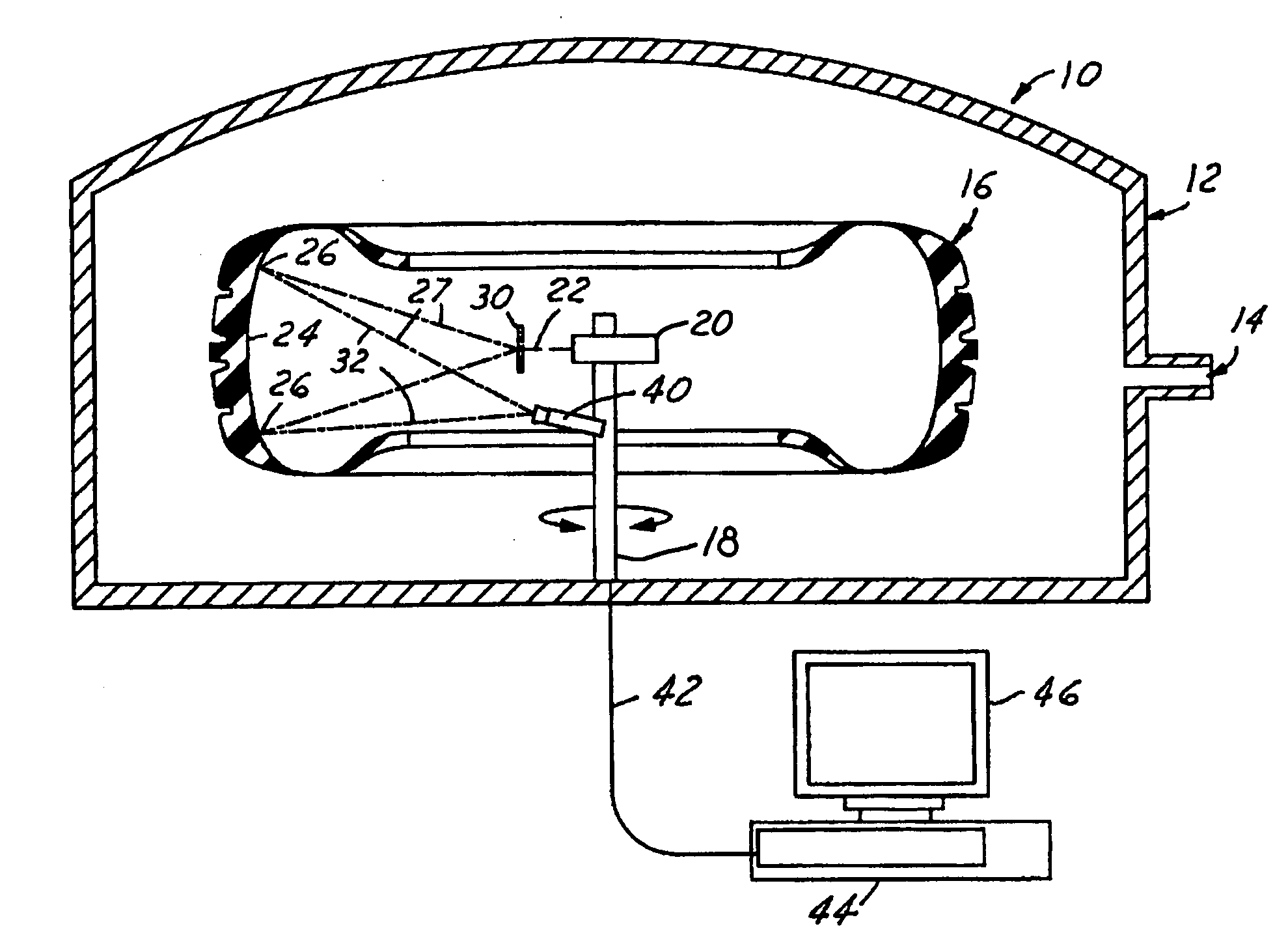

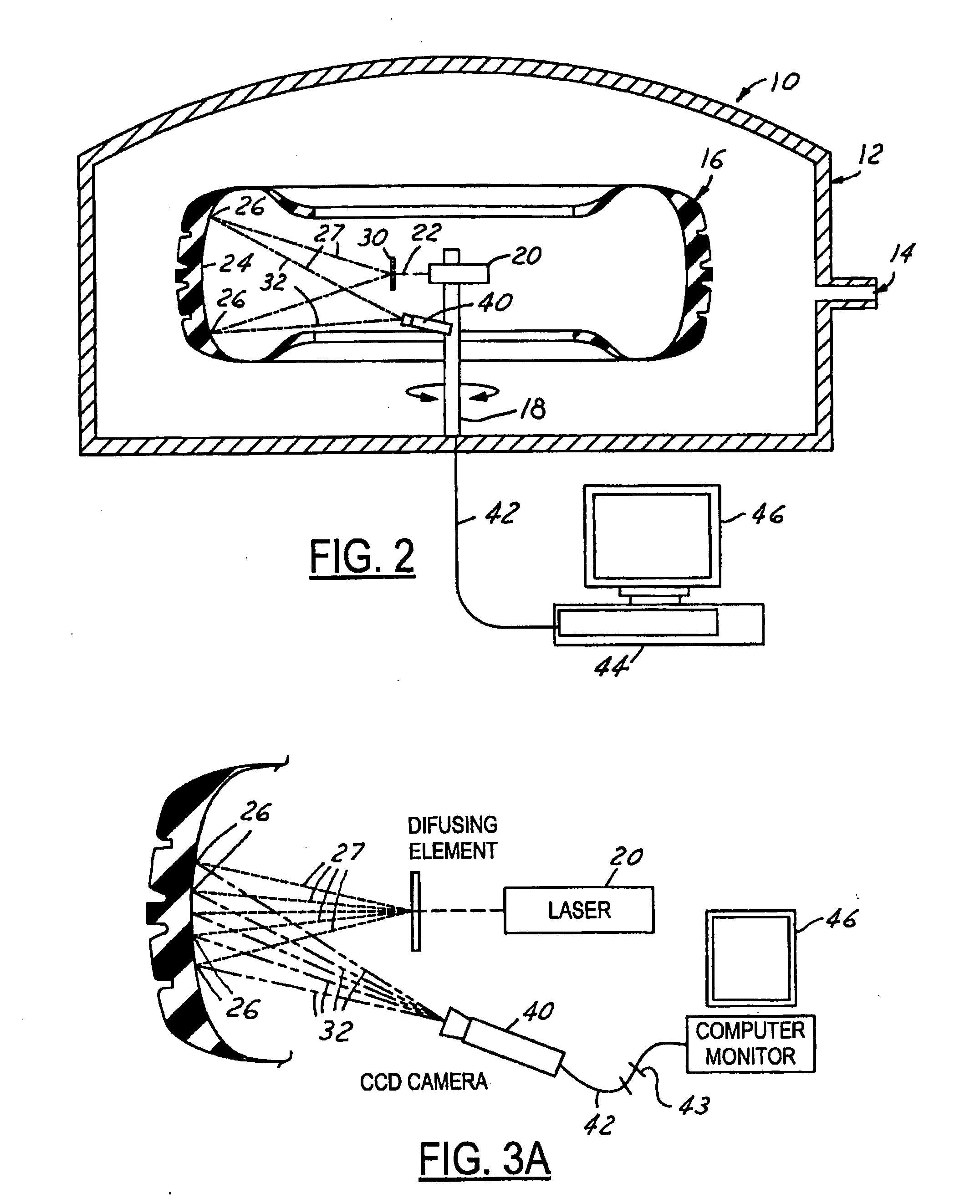

Method used

Image

Examples

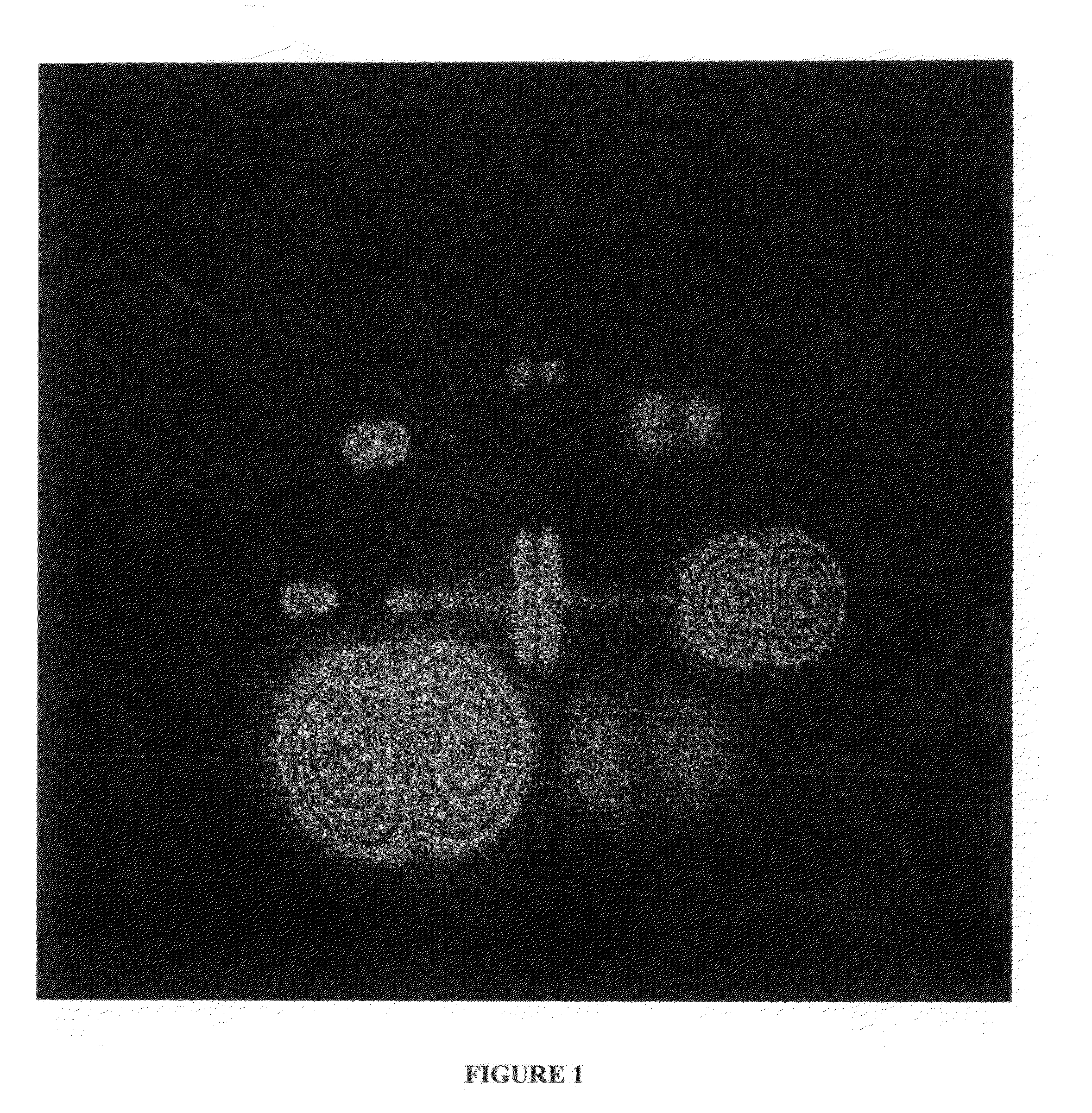

Embodiment Construction

Definitions

[0054]Anomaly is defined as a defect in a tire which can generally be characterized as air trapped in a cured tire as a result of variations in the thickness of the tire components; porosity and voids in the tire, a separation, an undercure of the tire, trapped air and bubbles; low interply adhesion, poor cord adhesion, bare wires, broken cords, and machine building errors.

[0055]Bitmap is a data file or structure which corresponds bit for bit with an image displayed on a screen, preferably in the same format as it would be stored in the display's video memory or alternatively as a device independent bitmap. A bitmap is characterized by the width and height of the image in pixels and the number of bits per pixel which determines the number of shades of grey or colors it can represent.

[0056]Coherent light is a light having a single wavelength, frequency and phase. It is also radiant electromagnetic energy of the same, or almost the same wavelength, and with definite phase r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com