Liquid cooled heat dissipator

a heat dissipator and liquid cooled technology, which is applied in the direction of corrosion prevention, stationary conduit assemblies, coatings, etc., can solve the problems of not having high heat dissipation capability, not being improved, and not having the overall heat dissipation efficiency of liquid cooled heat dissipators as good as expected. , to achieve the effect of increasing the heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

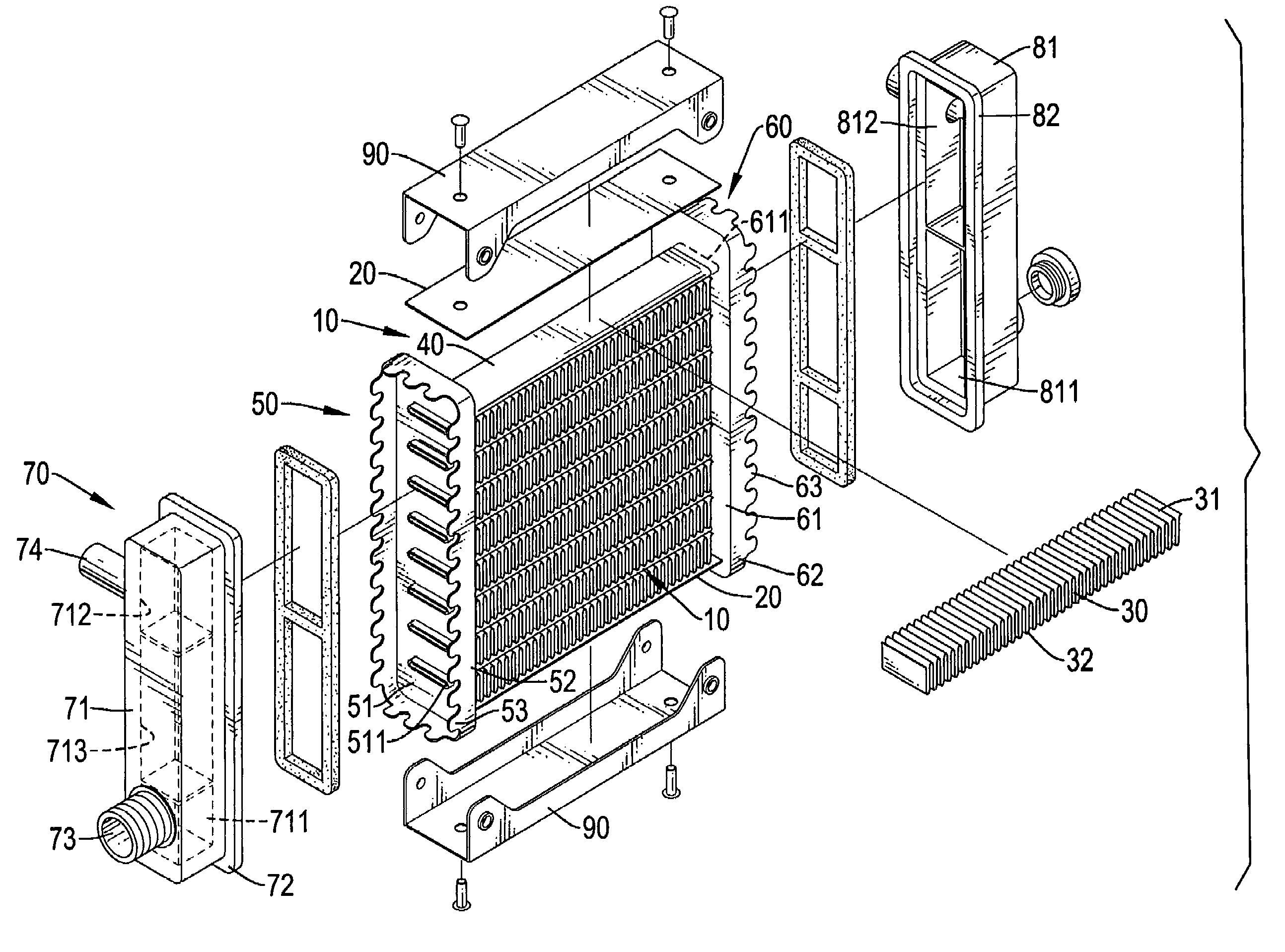

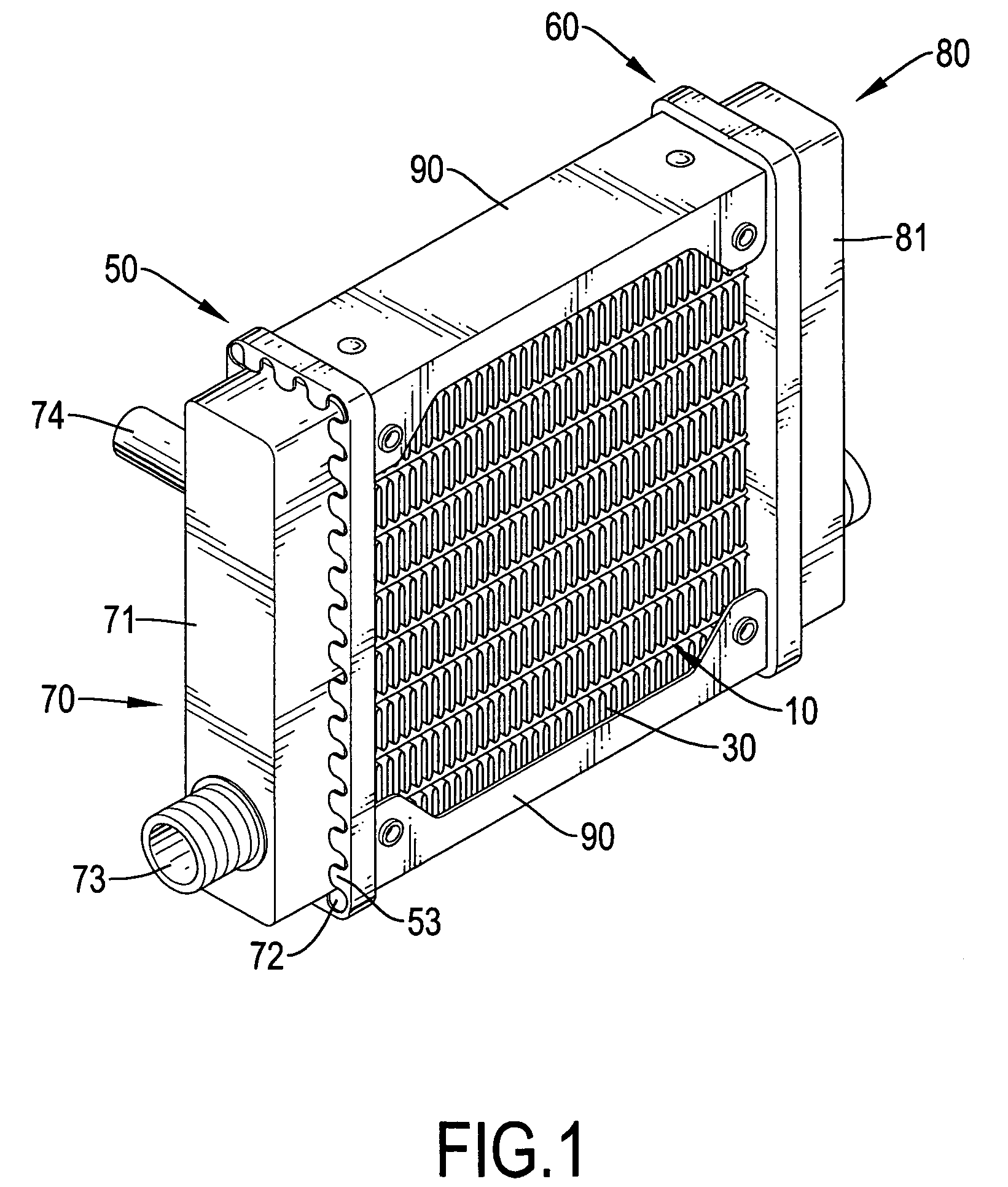

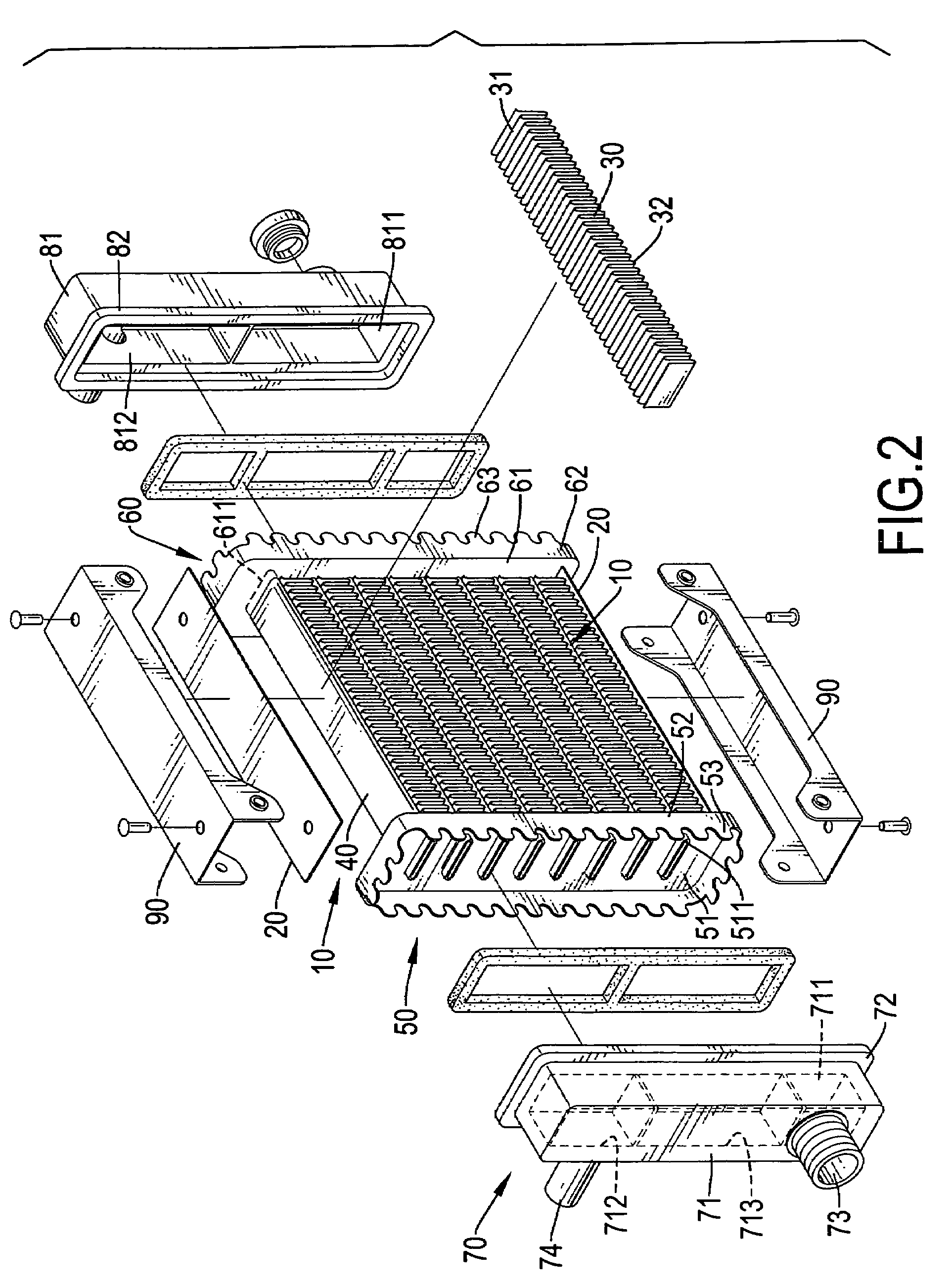

[0021]With reference to FIGS. 1, 2, 3 and 4, it is noted that the liquid cooled heat dissipator in accordance with the present invention includes eight water channels (10) superposed on top of each other, two securing plates (20) respectively mounted on a top face of a top most water channel (10) and a bottom face of a bottom most water channel (10), multiple rows of heat dissipating fins (30) respectively and securely received in a corresponding one of the water channels (10), a layer of tin alloy welding layer (40) provided on two opposed inner side faces of each water channel (10) and between the securing plate (20) and the top most water channel (10) and between the securing plate (20) and the bottom most water channel (10), a first water tank mounting seat (50) formed on a side of the combined water channels (10), a second water tank mounting seat (60) formed on the other side of the combined water channels (10) to be opposite to the first water tank mounting seat (50), a first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat | aaaaa | aaaaa |

| transparent | aaaaa | aaaaa |

| heat dissipating efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com