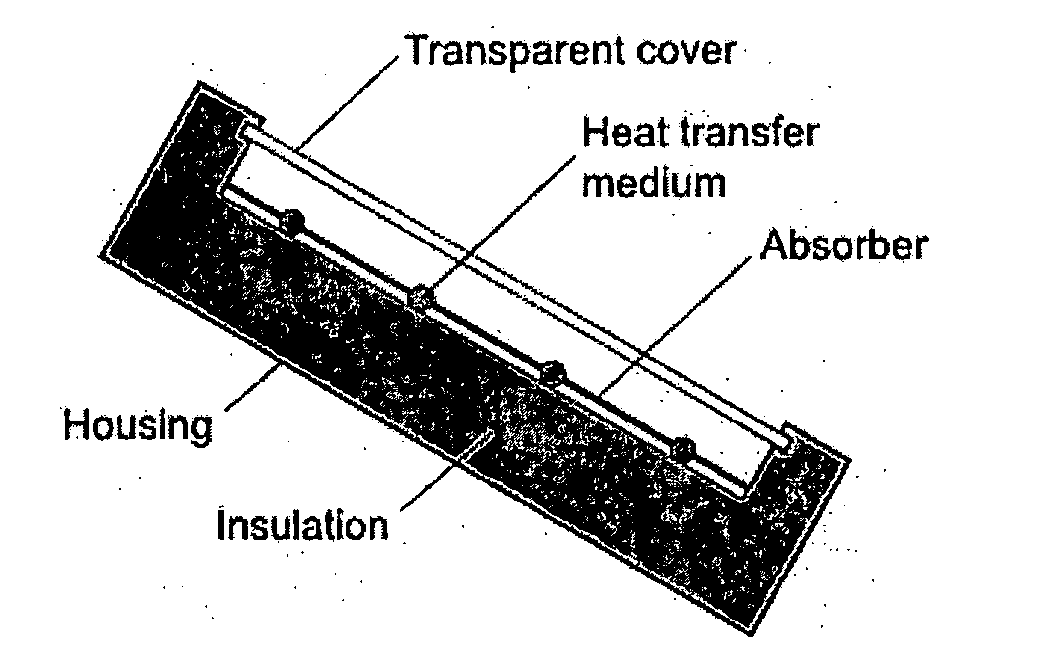

Solar collector

a solar collector and collector technology, applied in the field of solar collectors, can solve the problems of tracking collectors, reducing collector efficiency, and generally more expensive for the same performance characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

OF MMVF BINDER

[0048] In a first embodiment of the present invention, the formaldehyde-free polymeric binder system comprises the water-soluble reaction product of an alkanolamine with a carboxylic anhydride obtainable by reacting at least one alkanolamine with at least one carboxylic anhydride and, optionally, treating the reaction product with a base.

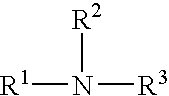

[0049] Preferred examples of alkanolamines for use in the preparation of this binder system include alkanolamines having at least two hydroxy groups such as, for instance, alkanolamines represented by the formula

wherein R1 is hydrogen, a C1-10 alkyl group or a C1-10 hydroxyalkyl group; and R2 and R3 independently are C1-10 hydroxyalkyl groups.

[0050] Preferably, R2 and R3 independently are C2-5 hydroxyalkyl groups, and R1 is hydrogen, a C1-5 alkyl group or a C2-5 hydroxyalkyl group. Particularly preferred hydroxyalkyl groups include β-hydroxyalkyl groups.

[0051] Specific and non-limiting examples of suitable alkanolamines include d...

second embodiment

OF MMVF BINDER

[0063] In a second aspect of the present invention, the formaldehyde-free polymeric binder system comprises an aqueous binder composition comprising:

[0064] (a) a polyacid component having acid groups, or anhydride or salt derivatives thereof; and

[0065] (b) a polyhydroxy component having hydroxyl groups;

[0066] wherein the pH of the binder composition is greater than about 7 and is preferably within the range of from about 7 to about 10.

[0067] In an exemplary embodiment, the composition includes a polyacid component and a polyhydroxy component where the ratio of the number of molar equivalents of acid groups, or anhydride or salt derivatives thereof, present on the polyacid component to the number of molar equivalents of hydroxyl groups present on the polyhydroxy component is in the range of from about 0.6:1 to about 1.2:1.

[0068] In another exemplary embodiment, the composition includes a polyacid component that is a dicarboxylic acid, including, but not limited to,...

third embodiment

OF MMVF BINDER

[0077] In a third aspect of the present invention, the formaldehyde-free polymeric binder system comprises a binder composition comprising a polycarboxy polymer (especially a polyacrylic acid polymer), a polyhydroxy crosslinking agent, and a surfactant selected from cationic surfactants, amphoteric surfactants, nonionic surfactants, and mixtures thereof.

[0078] The binder composition is prepared by polymerization of monomers (preferably acrylic acid) emulsified in water using conventional emulsion polymerization procedures. Suitable surfactants are used for emulsification of the monomers, including cationic, amphoteric or nonionic surfactants, and mixtures thereof, with nonionic surfactants being preferred.

[0079] The binder composition comprises an organic polymer or oligomer containing a plurality of pendant carboxy groups which may be a homopolymer or copolymer prepared from unsaturated carboxylic acids including acrylic acid, methacrylic acid, crotonic acid, isocro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com