Color electro-optic displays, and processes for the production thereof

a technology of electrooptic displays and color, applied in the direction of electrographic processes, originals for photomechanical treatment, instruments, etc., can solve the problems of inadequate service life of these displays, unable to meet the needs of use, and gas-based electrophoretic media are susceptible to the same types of problems, so as to enhance the adhesion of ink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

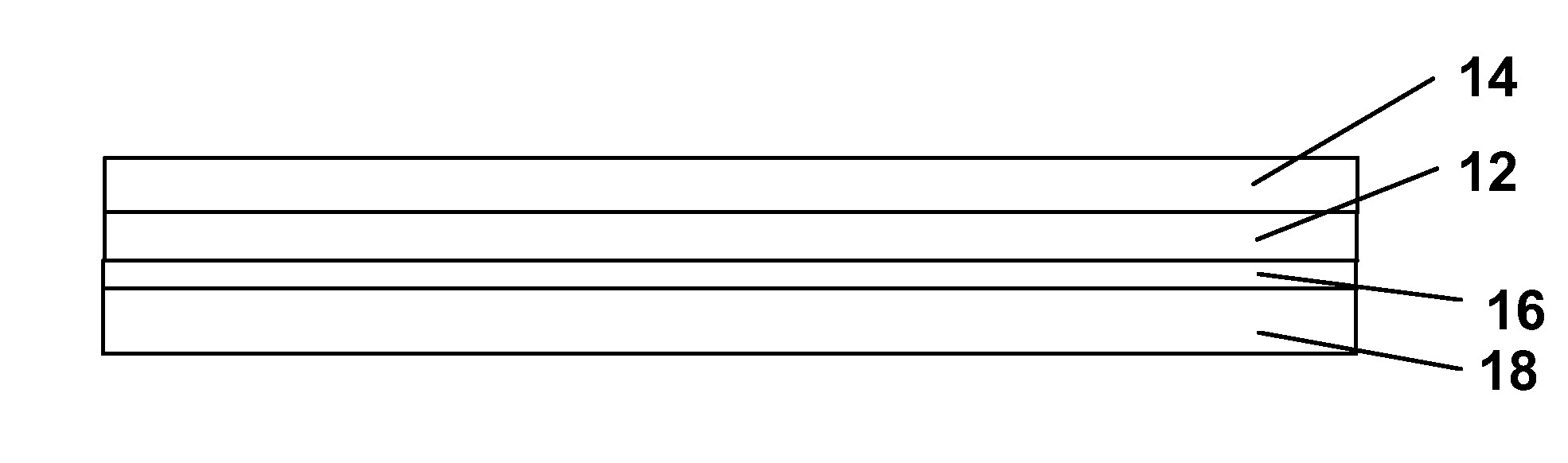

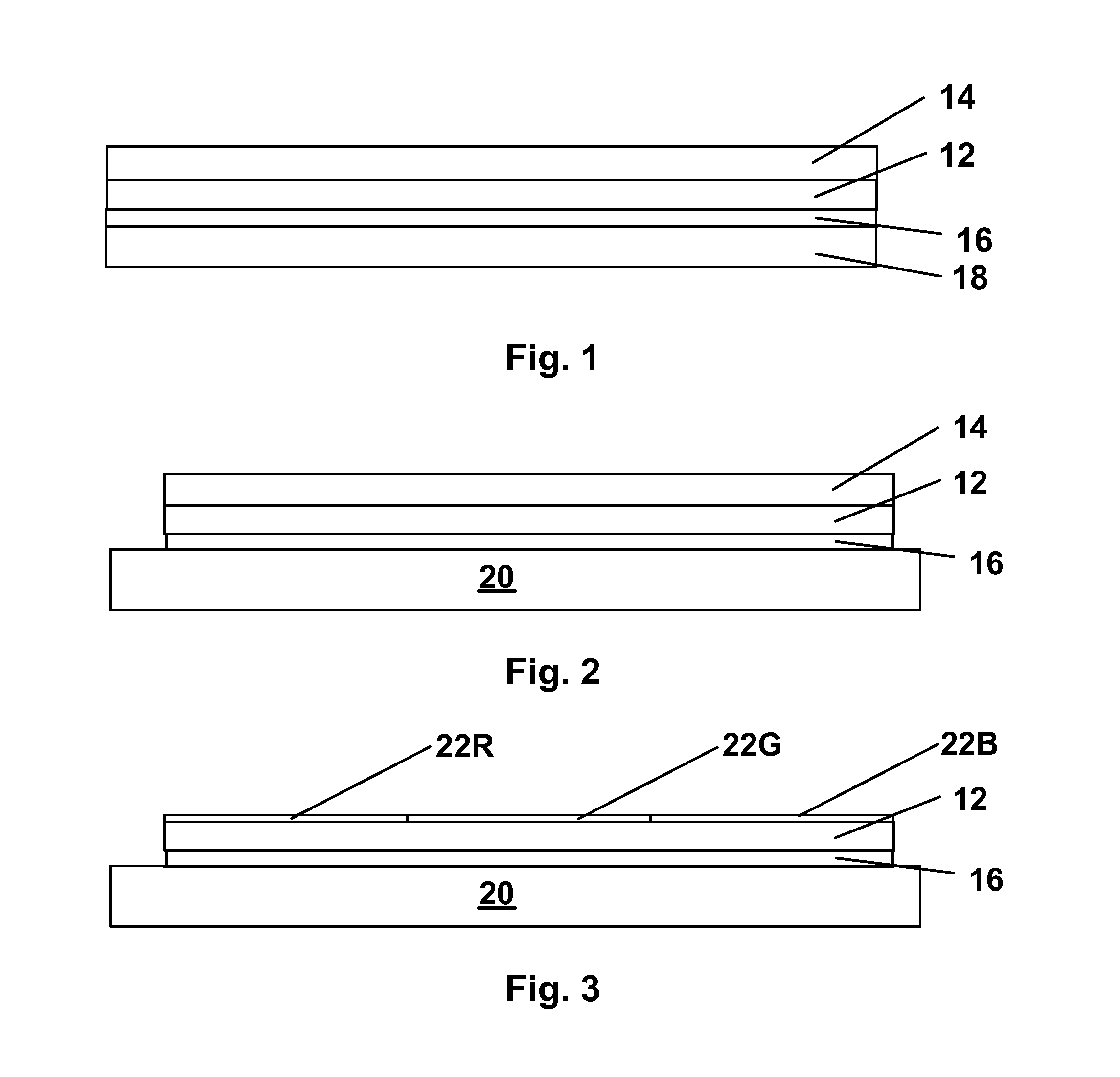

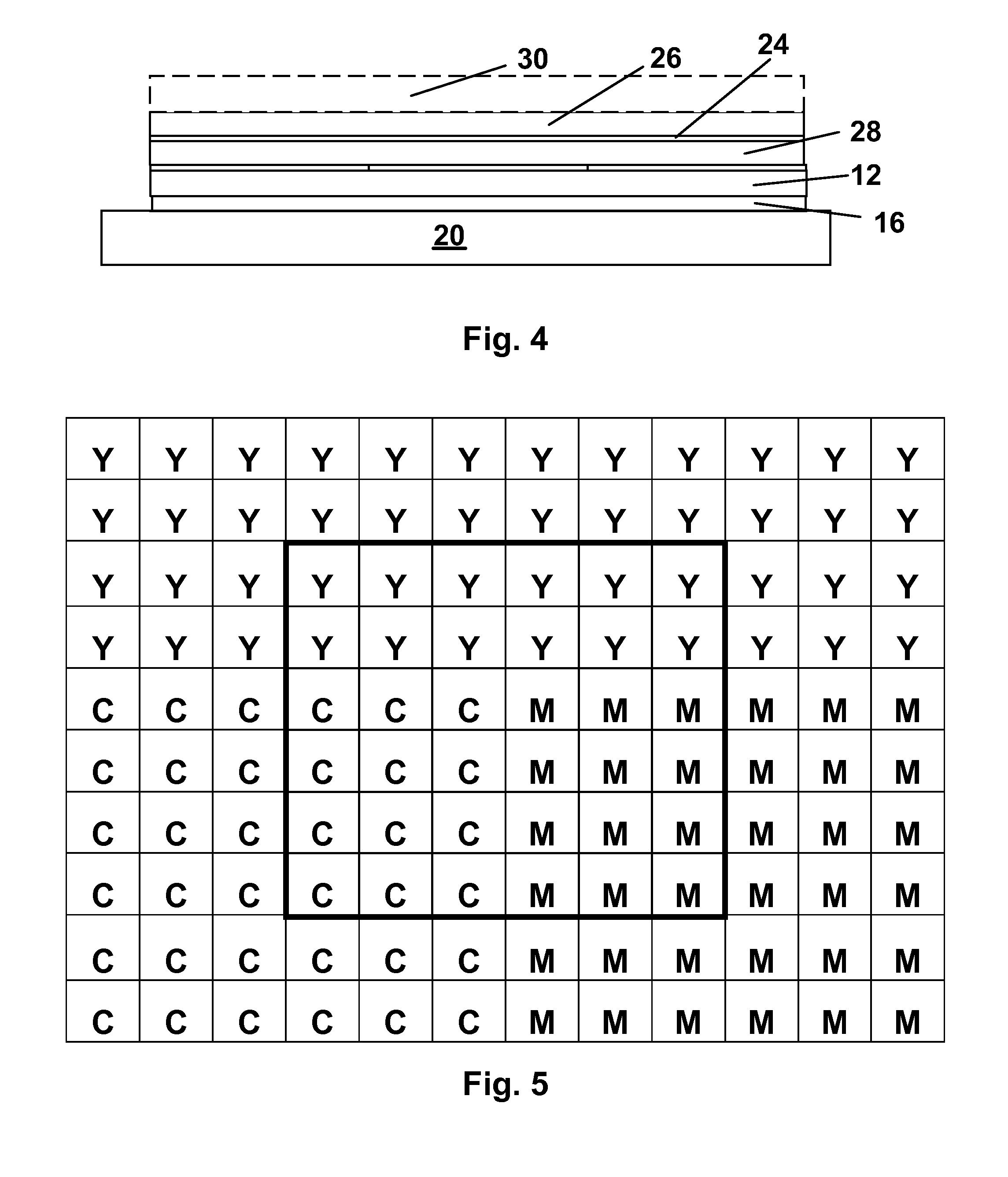

Image

Examples

example 1

[0104] This Example illustrates an adhesive layer printing process of the present invention using Construction Method C described above.

[0105] An encapsulated electrophoretic medium was prepared comprising gelatin / acacia capsules having an internal phase comprising polymer-coated titania white particles and polymer-coated copper chromite black particles in a hydrocarbon fluid. The capsules were formed into a slurry using an aqueous polyurethane binder substantially as described in Example 4 of the aforementioned U.S. Pat. No. 7,002,728. The resultant capsule slurry was slot coated on to a loose release sheet and dried to form a loose release sheet / capsule layer sub-assembly. Separately, a custom polyurethane adhesive was coated on to a tight release sheet, and then laminated to the loose release sheet / capsules layer sub-assembly, with the adhesive layer contacting the capsule layer. Separately, a polyacrylate adhesive was coated on to a loose release sheet. The loose release sheet ...

example 2

[0110] This Example illustrates a printed protective layer process of the present invention using Construction Method A above.

[0111] An encapsulated electrophoretic display was prepared by coating capsules similar to those described in Example 1 above on the ITO-coated surface of a PET / ITO film and drying, separately coating a custom polyurethane adhesive on to a release sheet, and laminating the adhesive / release sheet sub-assembly to the PET / ITO / capsule layer sub-assembly, with the adhesive contacting the capsule layer to form a front plane laminate. This front plane laminate was cut to size, the release sheet removed and the remaining layers laminated to a thin film transistor active matrix backplane to form a monochrome display. All the preceding steps were carried out substantially as described in the aforementioned U.S. Pat. No. 6,982,178.

[0112] The display thus prepared was ink jet printed using the same printer and inks as in Example 1 above. Printing was effected using the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electrical conductor | aaaaa | aaaaa |

| Electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com