Rigid-flexible printed circuit board and method of manufacturing the same

a printed circuit board, rigid technology, applied in the direction of cross-talk/noise/interference reduction, lithographic masks, etching metal masks, etc., can solve the problems of high cost of processing, high cost of applying and removing resists, high manufacturing cost, etc., to eliminate the cost of previously processing, easy to perform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

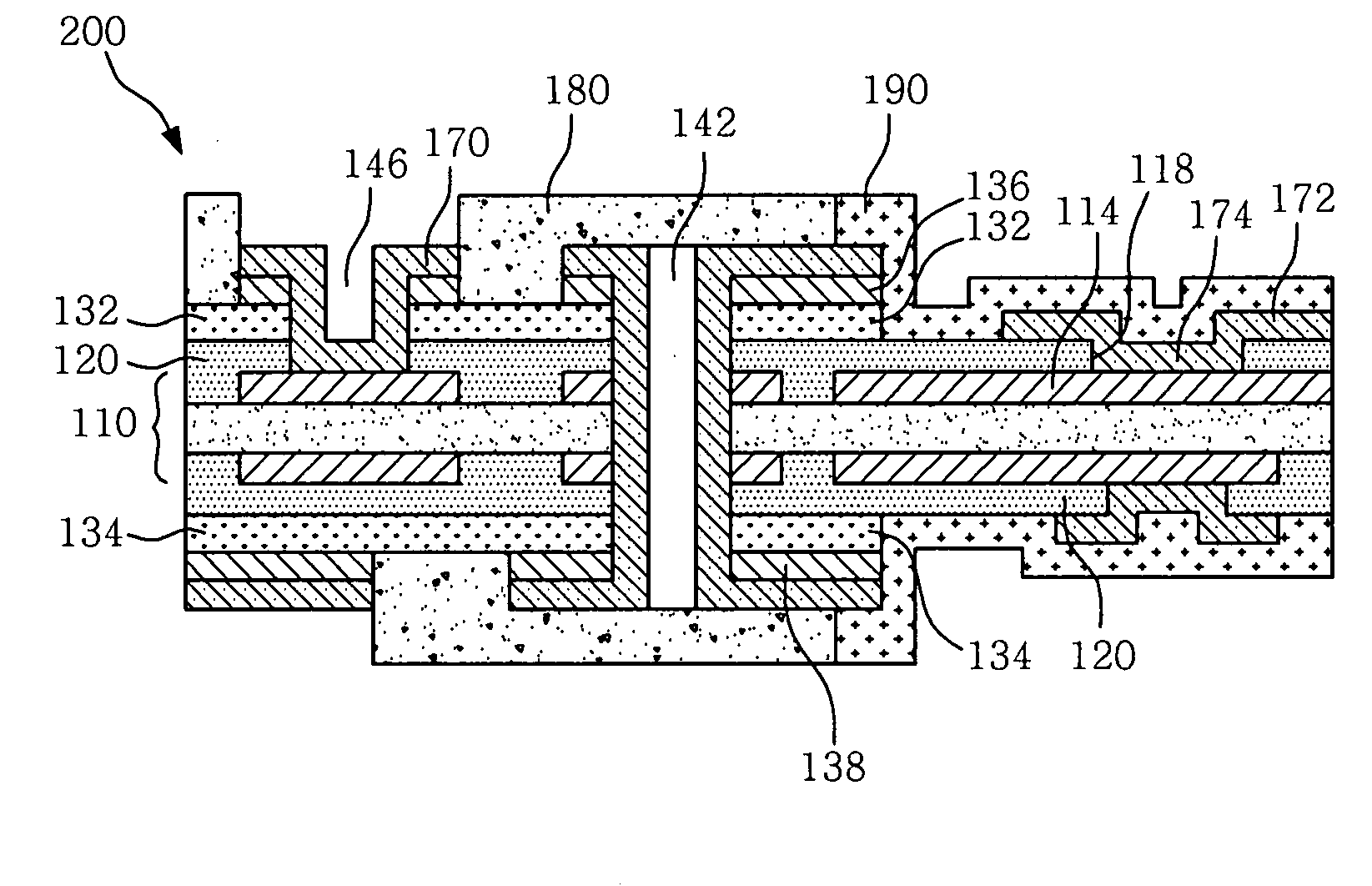

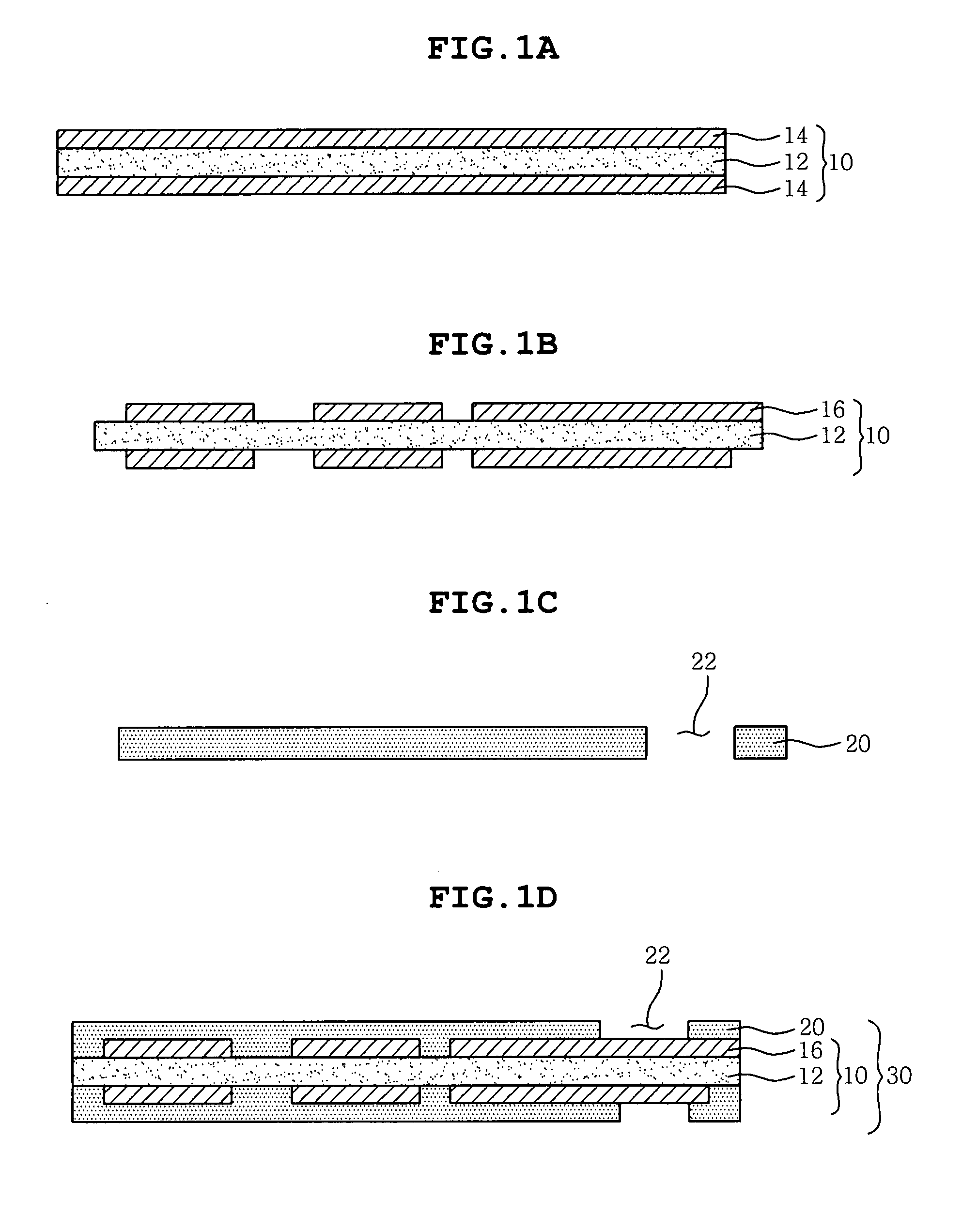

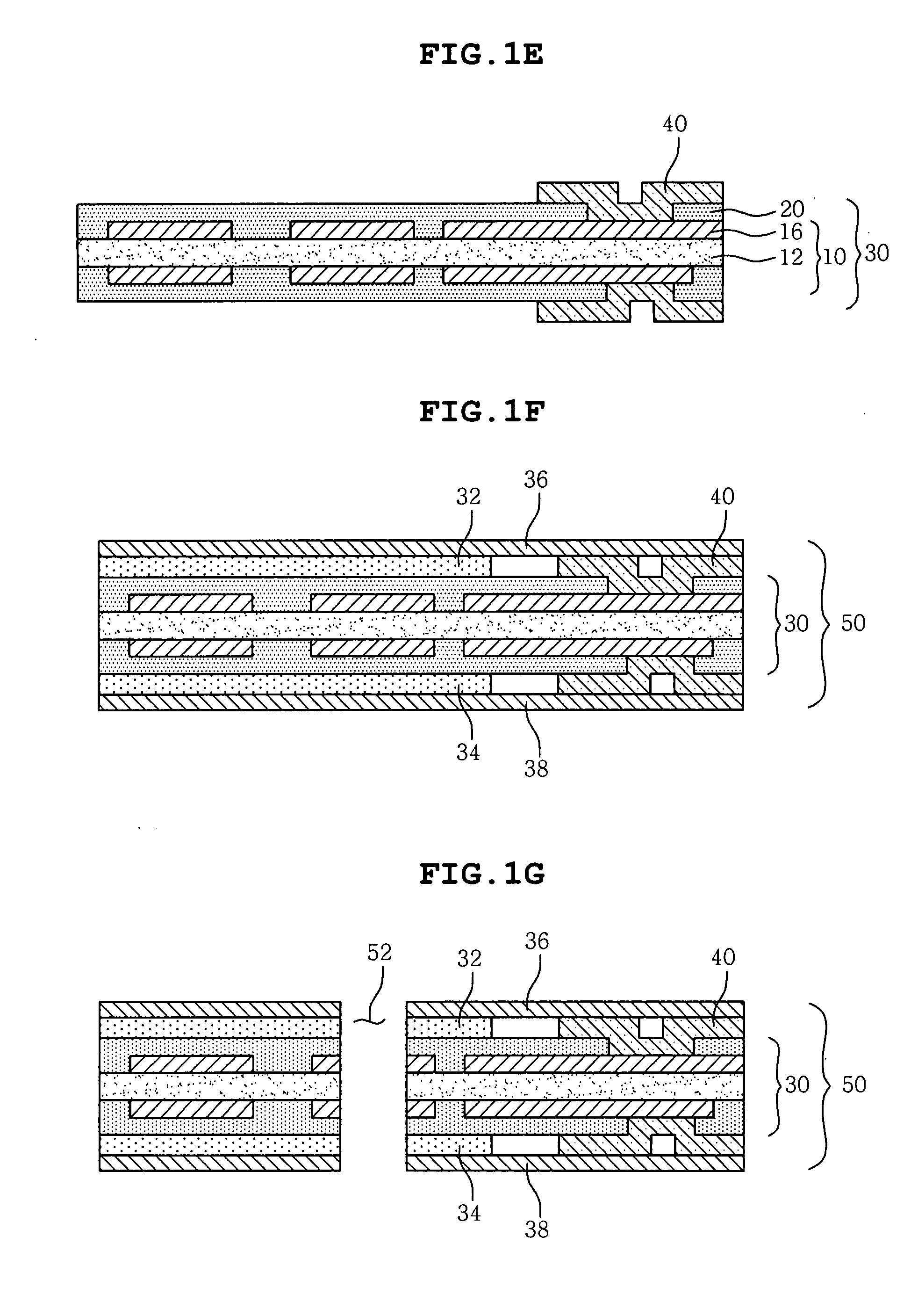

[0052]FIG. 3 is a flow chart schematically showing a method of manufacturing a rigid-flexible printed circuit board according to the present invention.

[0053]The method of manufacturing a rigid-flexible printed circuit board according to the first embodiment of the present invention is performed through the following steps.

[0054]First, a base substrate, in which coverlays are formed over two sides of a double-sided FCCL on both sides of which inner circuit patterns are formed, is provided (S110). Insulation layers and copper foil layers are layered on the portions of coverlays which are to be a rigid region of the double-sided FCCL (S120). A via hole is formed in the rigid region using a CO2 laser, and simultaneously first windows are formed in the coverlays of the flexible region (S130).

[0055]An entire plating layer is formed over the entire area, and outer circuit patterns including a region around the first window are formed from the plating layer (S140). Then, solder resists are ...

second embodiment

[0071]FIG. 5 is a flow chart schematically showing a method of manufacturing a rigid-flexible printed circuit board according to the present invention.

[0072]The method of manufacturing a rigid-flexible printed circuit board according to the second embodiment of the present invention is performed through the following steps.

[0073]First, a base substrate, in which coverlays are respectively formed on two sides of a double-sided FCCL on both sides of which inner circuit patterns and first windows are respectively formed, is provided (S210). Insulation layers and copper foil layers are layered on the portions of coverlays which are to be the rigid region of the double-sided FCCL (S220). A via hole is formed in the rigid region using a CO2 laser and, simultaneously, another via hole is formed to correspond to the first window in the flexible region (S230).

[0074]An entire plating layer is formed over the entire area, and outer circuit patterns including a region around the first window ar...

third embodiment

[0094]FIG. 7 is a flow chart schematically showing a method of manufacturing a rigid-flexible printed circuit board according to the present invention.

[0095]The method of manufacturing a rigid-flexible printed circuit board according to the third embodiment of the present invention is performed through the following steps.

[0096]First, a base substrate, in which coverlays are respectively formed on two sides of a double sided FCCL, on both sides of which inner circuit patterns and first window are formed, is provided (S310). Insulation layers and copper foil layers are respectively layered on the portions of coverlays which are to be a rigid region of the base substrate (S320). A via hole is formed in the rigid region using an ultraviolet laser, and simultaneously another via hole is formed in the flexible region (S330).

[0097]An entire plating layer is formed over the entire area, and outer circuit patterns including a region around the via holes are formed from the plating layer (S3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexible | aaaaa | aaaaa |

| diameters | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com