Sanitary Thin Paper and Process for Producing the Same

a technology of thin paper and sanitary paper, which is applied in the field of sanitary thin paper, can solve the problems of difficult to find suitable lubricant and unfavorable touch comfort, and achieve the effects of enhancing bulkiness, and reducing friction between fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0080] Examples of the invention are described below.

[0081] Samples for a tissue paper and a toilet paper were evaluated while comparing between the types of additives added. The results are shown in Table 1. The additives employed were included in Table 1.

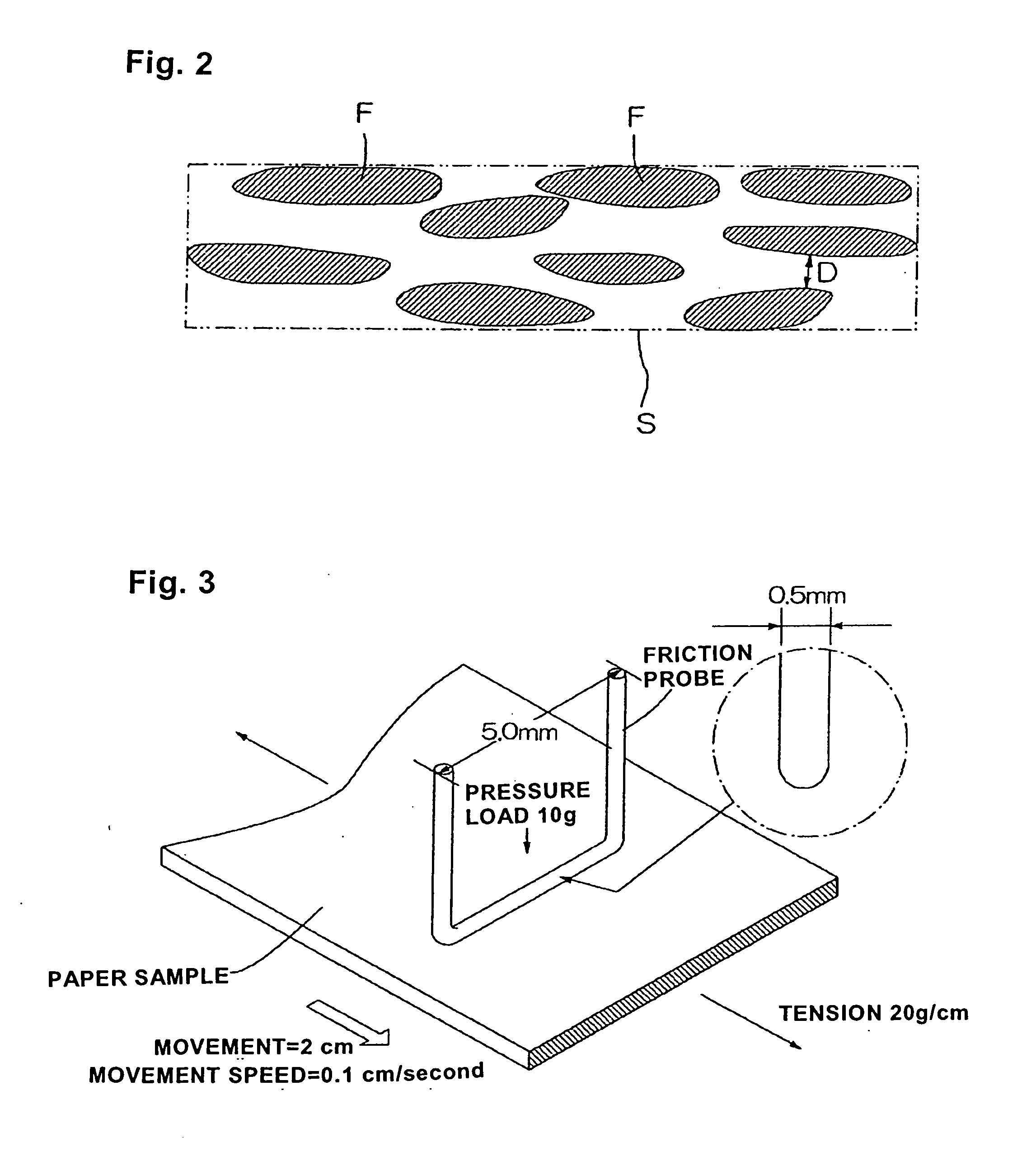

[0082] The evaluation was made by measuring an MIU value related to the friction coefficient using a KES test machine manufactured by KATO TECH CO., LTD. A smaller value reflects a smoother texture.

[0083] Also under an electron microscope observation, the fiber fluffiness on the surface of the paper was observed, since only MIU values are insufficient for the evaluation.

[Table 1]

[0084] Based on these results, an inventive product was evaluated in a sensory test to be excellent both in terms of “softness” and “smoothness”. A total fluff length of 0.1 mm or longer and a large total number of fluffs of 0.1 mm or longer, as observed here, reflect a higher smoothness. This is because of the presence of a large number of long fluff...

example 2

[0085] A commercially available tissue paper and an inventive tissue paper were compared in various profiles. Each was tested as a 2-ply (two sheets make a unit) sample. The results are shown in Table 2.

[0086] The softener employed here are listed below. The results are shown in Table 2.

[0087] The softener employed here are listed below. Softener A: Nonionic fatty acid ester (NIPPON PMC, SFS1001) Softener B: Cationic fatty acid ester (NIPPON PMC, SFS1002) Softener C: Cationic fatty acid ester (NIPPON PMC, SFS1004) Softener D: Cationic fatty acid amide (NOF, bulk agent J)

[0088] The sensory test was on the basis of 5-point evaluation. A % void area and a % fiber number were measured by stacking 6 samples whose top and bottom were covered with OHP sheets, which was cut by a sharp shaving blade at an angle of 90°, and the sectional view of a sample after cutting was taken as a ×1000 SEM photograph, which was then evaluated.

[Table 2]

[0089] Based on these results, an inventive produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com