Method and Apparatus for Electrically Connecting Two Substrates Using a Resilient Wire Bundle Captured in an Aperture of an Interposer by a Retention Member

a technology interposers, which is applied in the direction of coupling device connections, fixed connections, coupling device details, etc., can solve the problems of catastrophic damage to one or both of the electronic substrates being interconnected, loosening and falling out of the interposer, so as to improve the retention of resilient wire bundles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

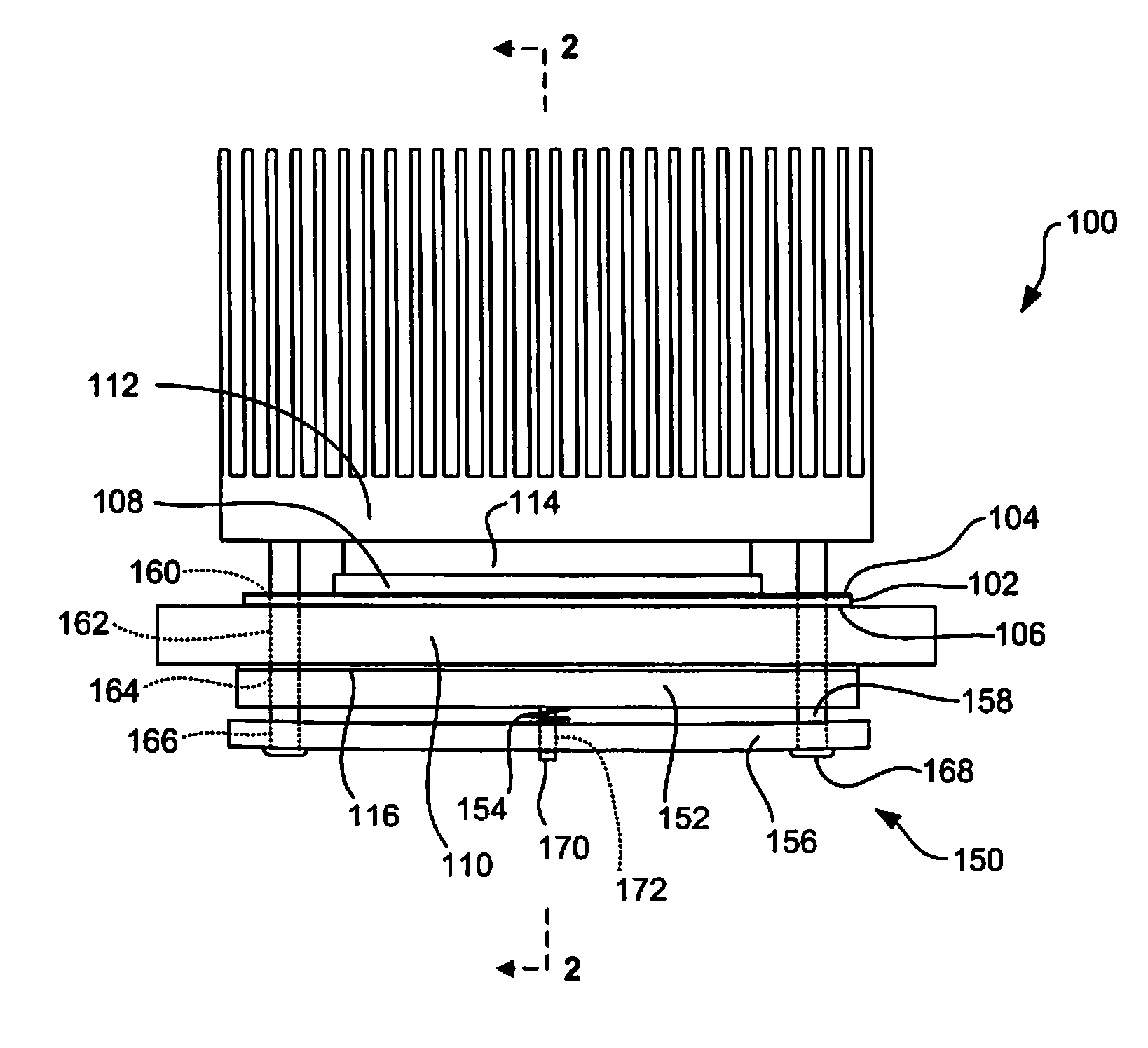

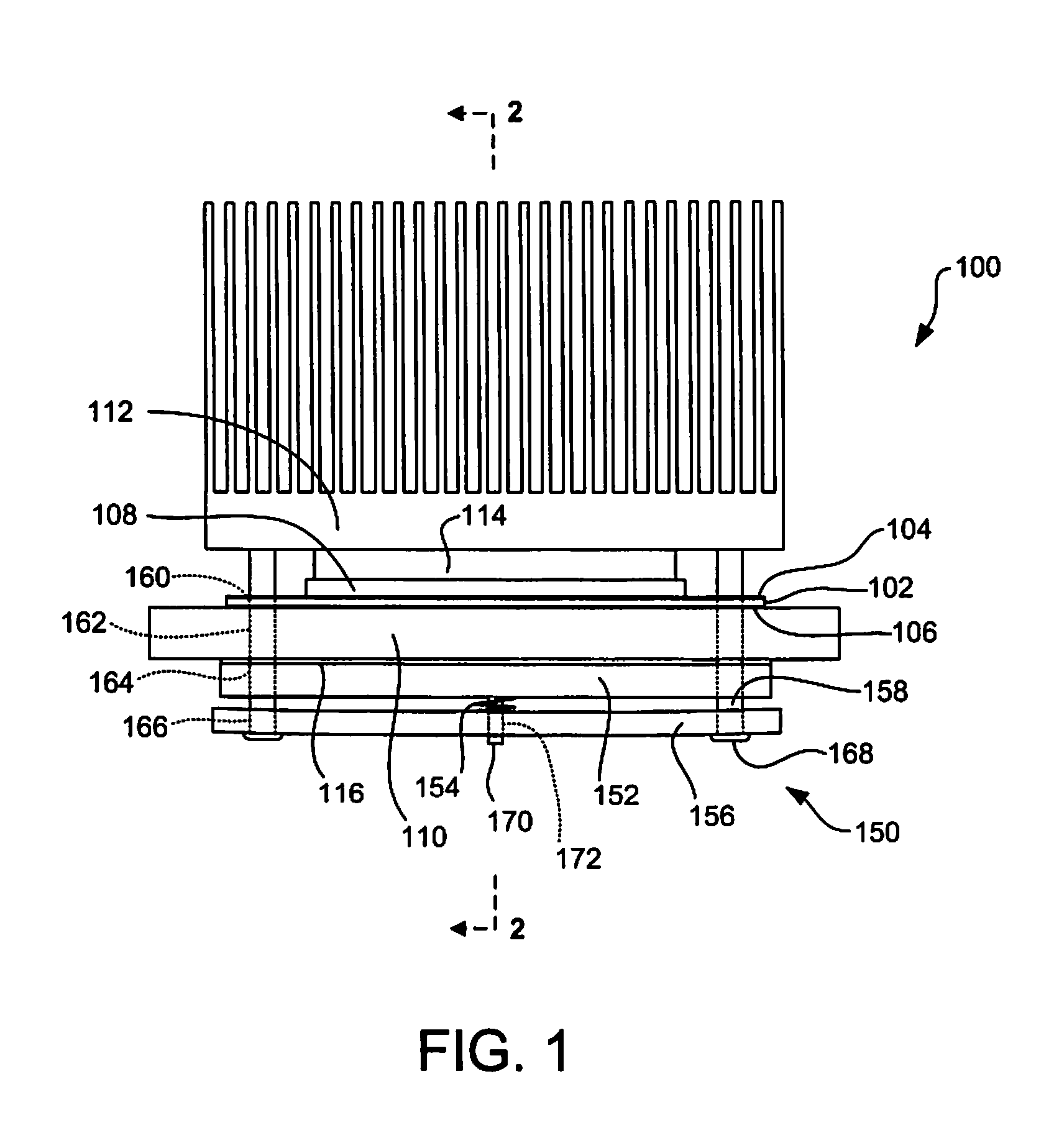

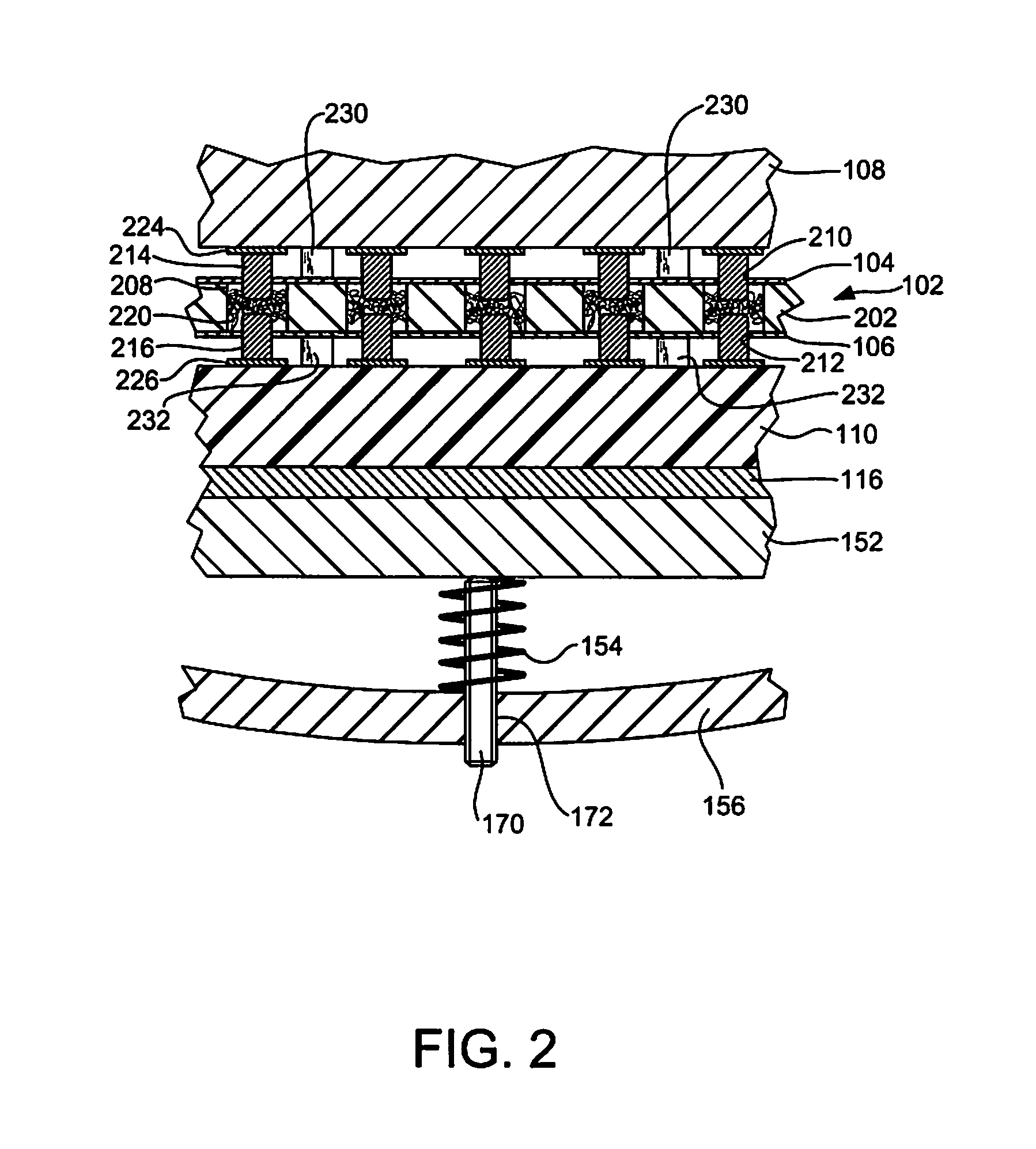

[0023] 1.0 Overview

[0024] In accordance with the preferred embodiments of the present invention, two subtrates are electrically connected using resilient wire bundles captured in apertures of an interposer by a retention member. The interposer comprises an electrically non-conductive carrier having two surfaces and apertures extending from surface to surface. A resilient wire bundle is disposed in each aperture. An electrically non-conductive retention member, such as a thin polyimide film, is associated with one or both surfaces of the carrier and has an orifice overlying each aperture. The width of each orifice is smaller than that of the underlying aperture to thereby enhance retention of the resilient wire bundle within the aperature. Pin contacts of one or both of the substrates make electrical contact with the resilient wire bundles by extending through the orifices of the retention member and partially through the apertures. In one embodiment of the present invention, the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com