Particulate trap regeneration system and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

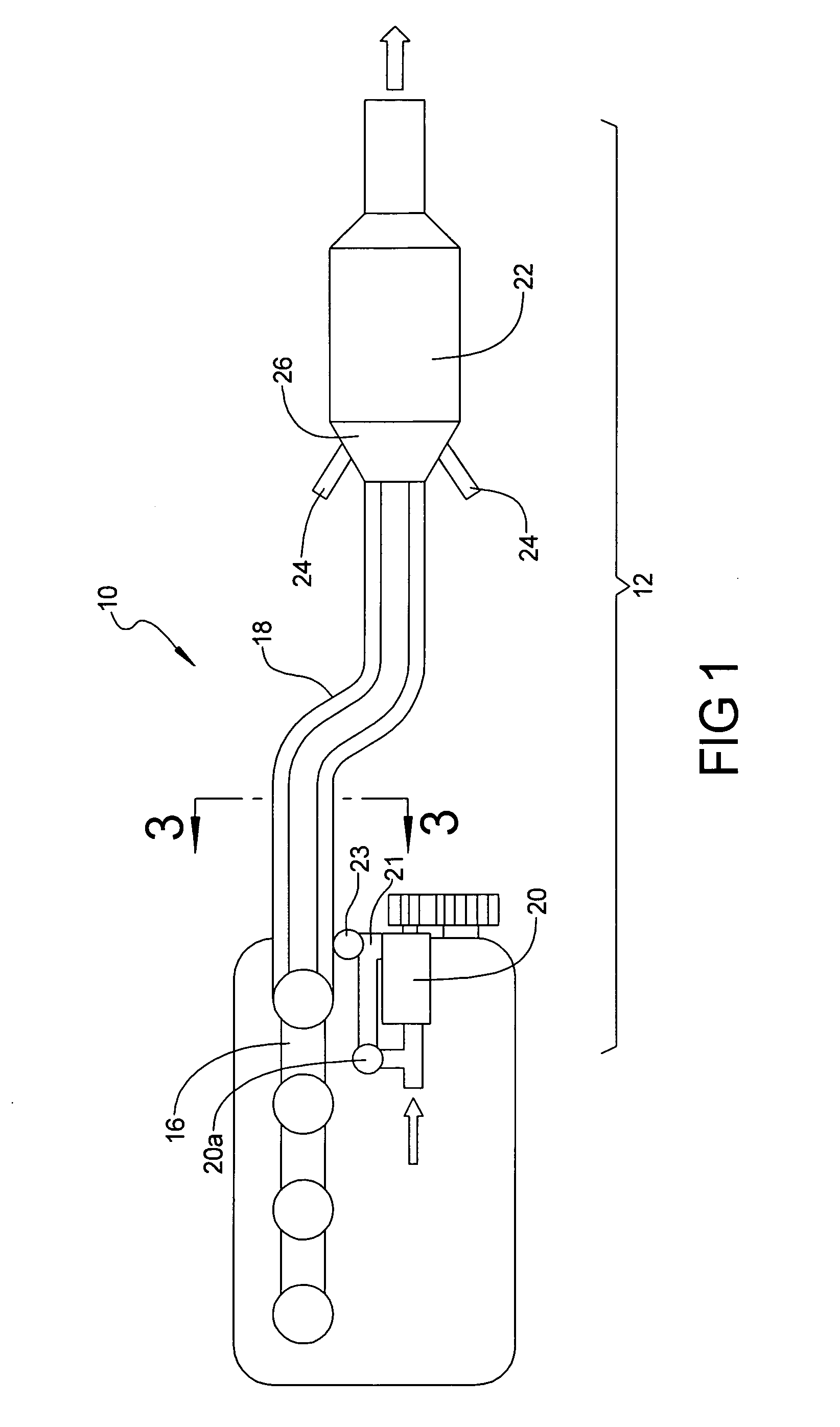

[0011]FIG. 1 shows an engine system 10 that incorporates a particulate trap regeneration system 12 according to one embodiment of the invention. The engine system 10 includes an engine 14 having an exhaust manifold 16 that sends exhaust through an exhaust pipe 18. In one embodiment, the exhaust pipe 18 has a double-walled 19a, 19b structure that keeps the outside of the exhaust pipe 18 relatively cool (FIG. 2). The double walled exhaust pipe 18 also provides a space 19c between the walls for air to flow through and be heated by heat radiating through the inner wall 19b from the exhaust. Note that other exhaust pipe configurations are possible without departing from the scope of the invention as long as there are two pipe channels that share at least one wall through which heat from the exhaust in one channel is captured by air traveling through the adjoining channel.

[0012] To further promote heat transfer, the exhaust pipe 18 may include a plurality of fins 19c that extend radially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com