Burning wick structure

a technology of burning wick and wick body, which is applied in the direction of burning wicks, combustion types, combustion processes, etc., can solve the problems of serious affecting the health of the human body, conventional structure is not safe to use, and prone to potential danger, so as to reduce the potential reduce the danger of burning wick. , the effect of improving the effect of insufficient burning of burning liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the Examiner further understand the present invention, the characteristics and the technical contents of the present invention will be explained with reference to the detailed description and the accompanying drawings. However, it should be understood that the drawings are illustrative but not used to limit the scope of the present invention.

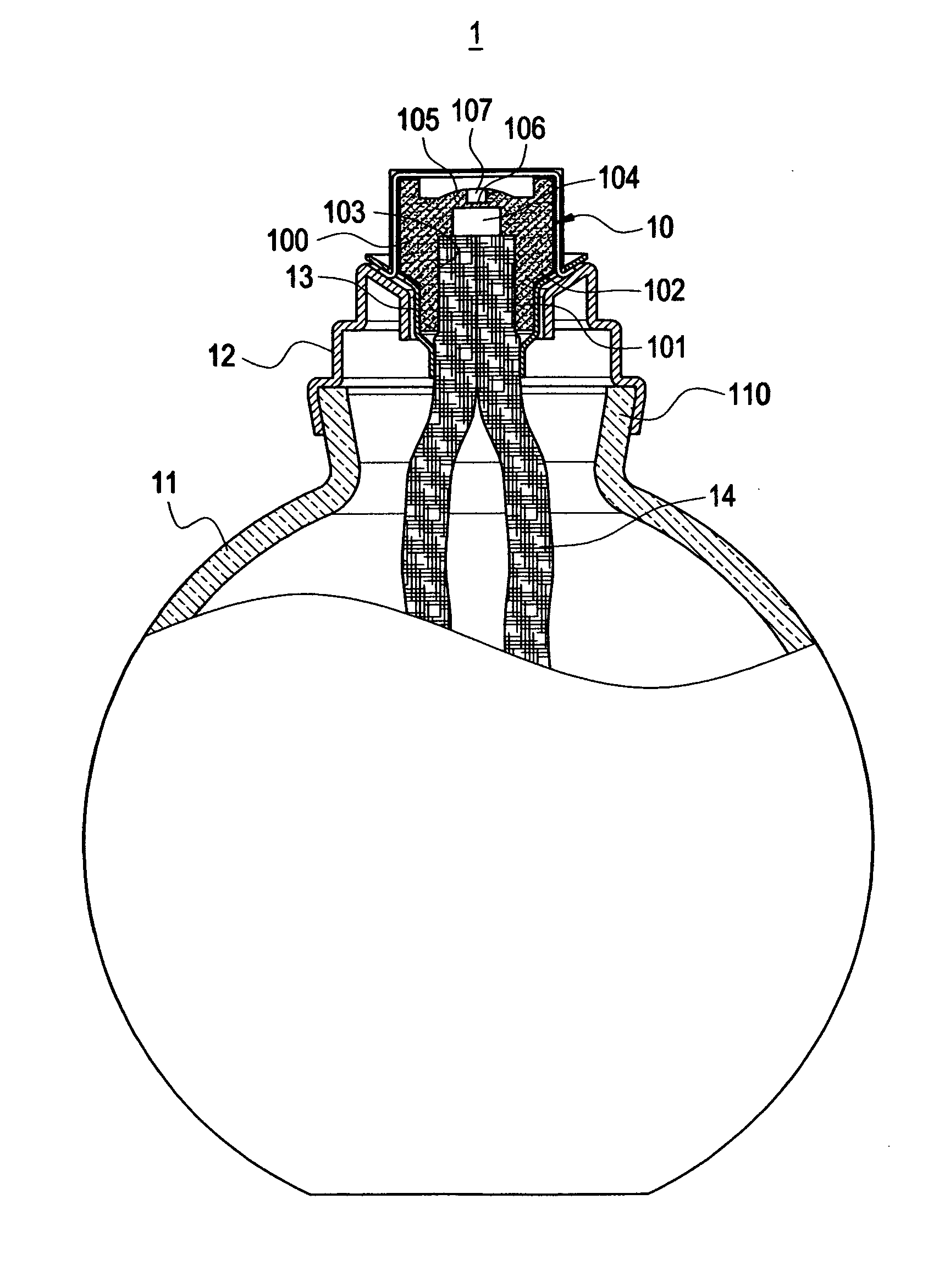

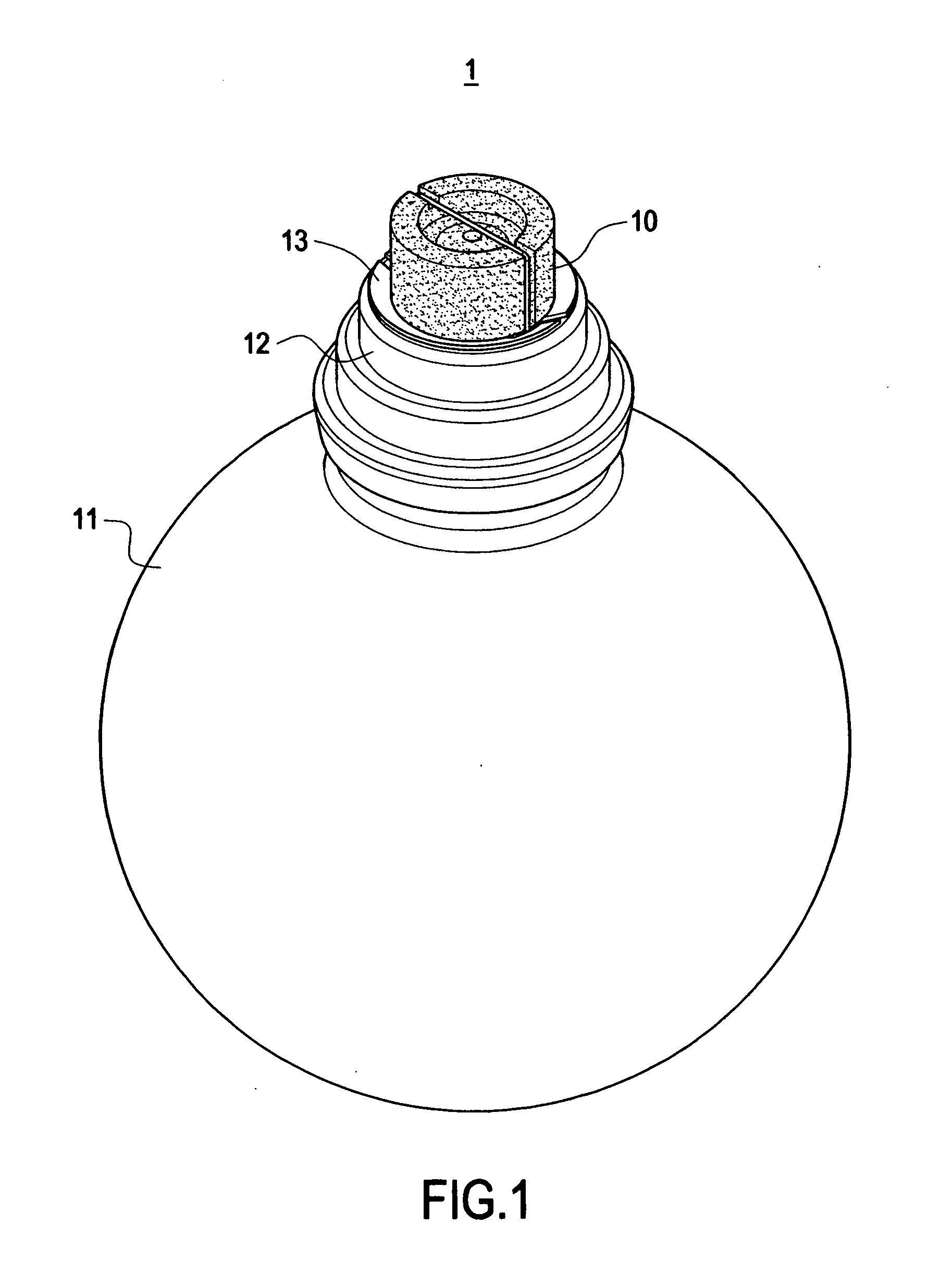

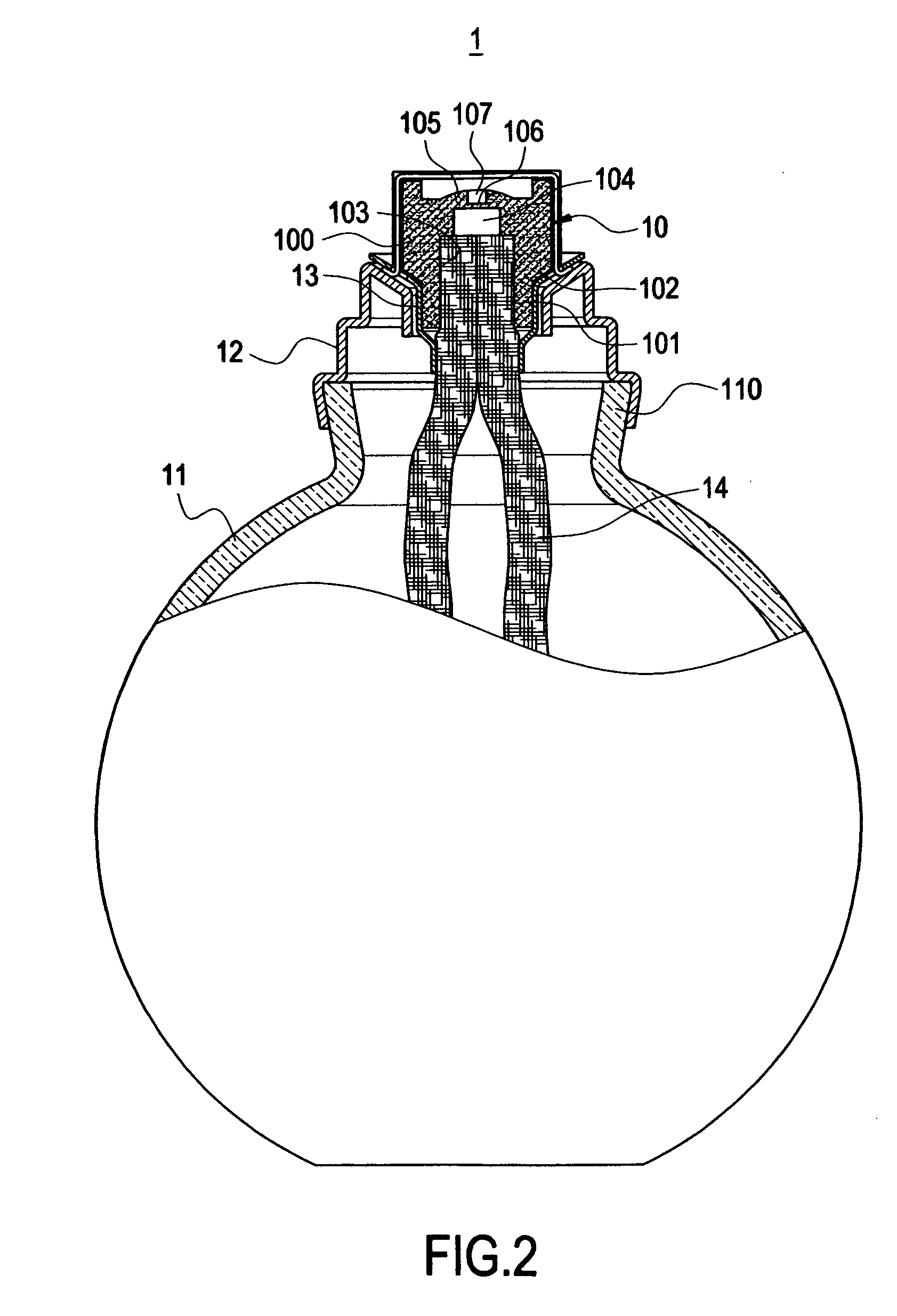

[0017]FIG. 1 is a perspective view showing the external appearance of the burning device of the present invention, and FIG. 2 is a partial cross-sectional view of the burning device of the present invention. The present invention provides an improved structure of burning wick. The burning wick 10 is used for being arranged on a burning device 1 (such as an essential oil lamp). The burning device 1 mainly includes a hollow bottle body 11, a mouth cap 12 provided on a mouth 110 of the bottle body 11, a heat-resistant ring 13 provided on the top portion of the mouth cap 12, and the burning wick 10. The burning wick 10 is su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com