Animal-resistant resilient trash container and lid mechanism

a technology of latching mechanism and trash container, which is applied in the directions of refuse gathering, transportation and packaging, packaging, etc., can solve the problems of unfavorable attractivity of automated collection and emptying of bins, and food waste which can unfavorably attract pests and potentially dangerous animals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

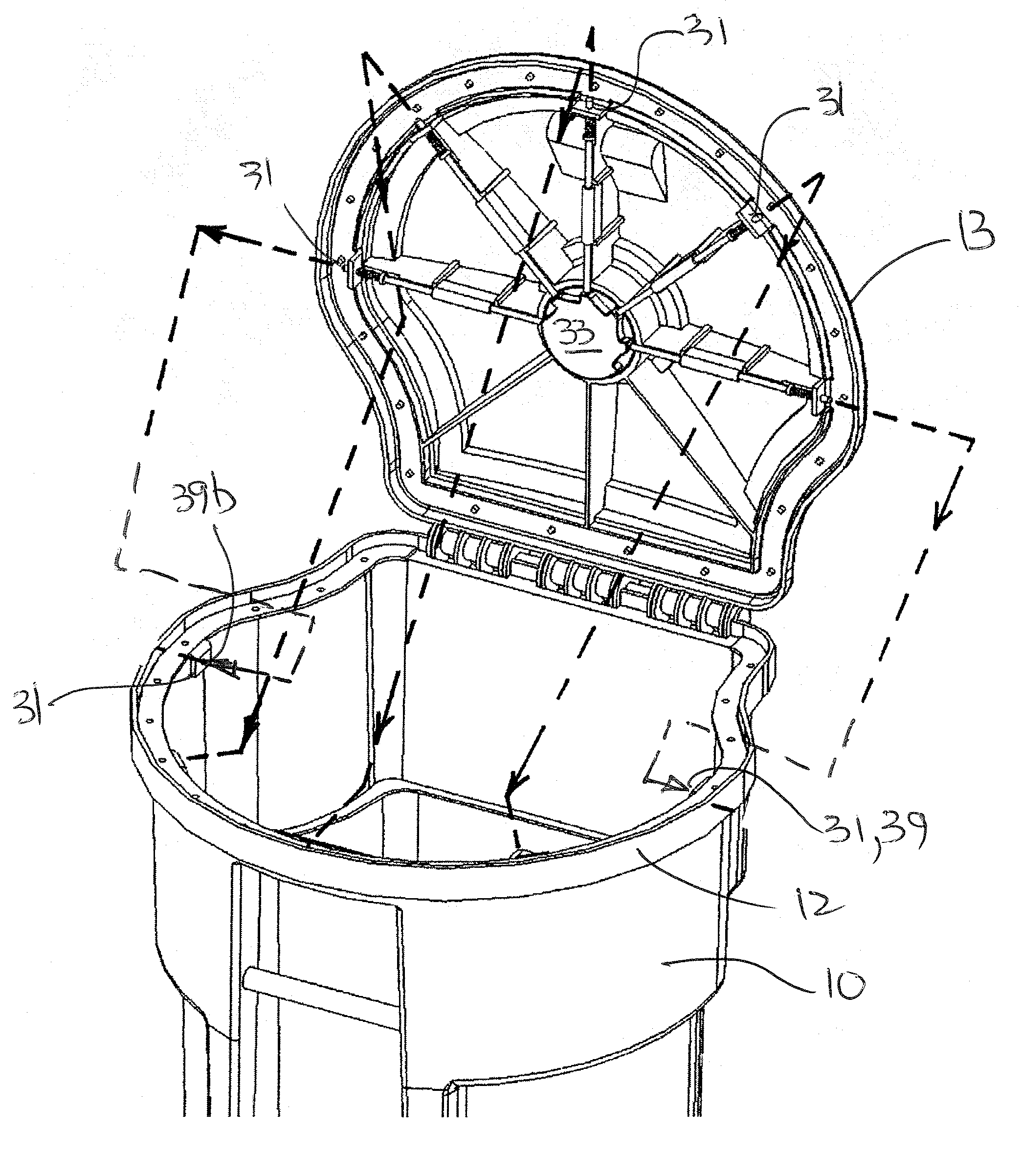

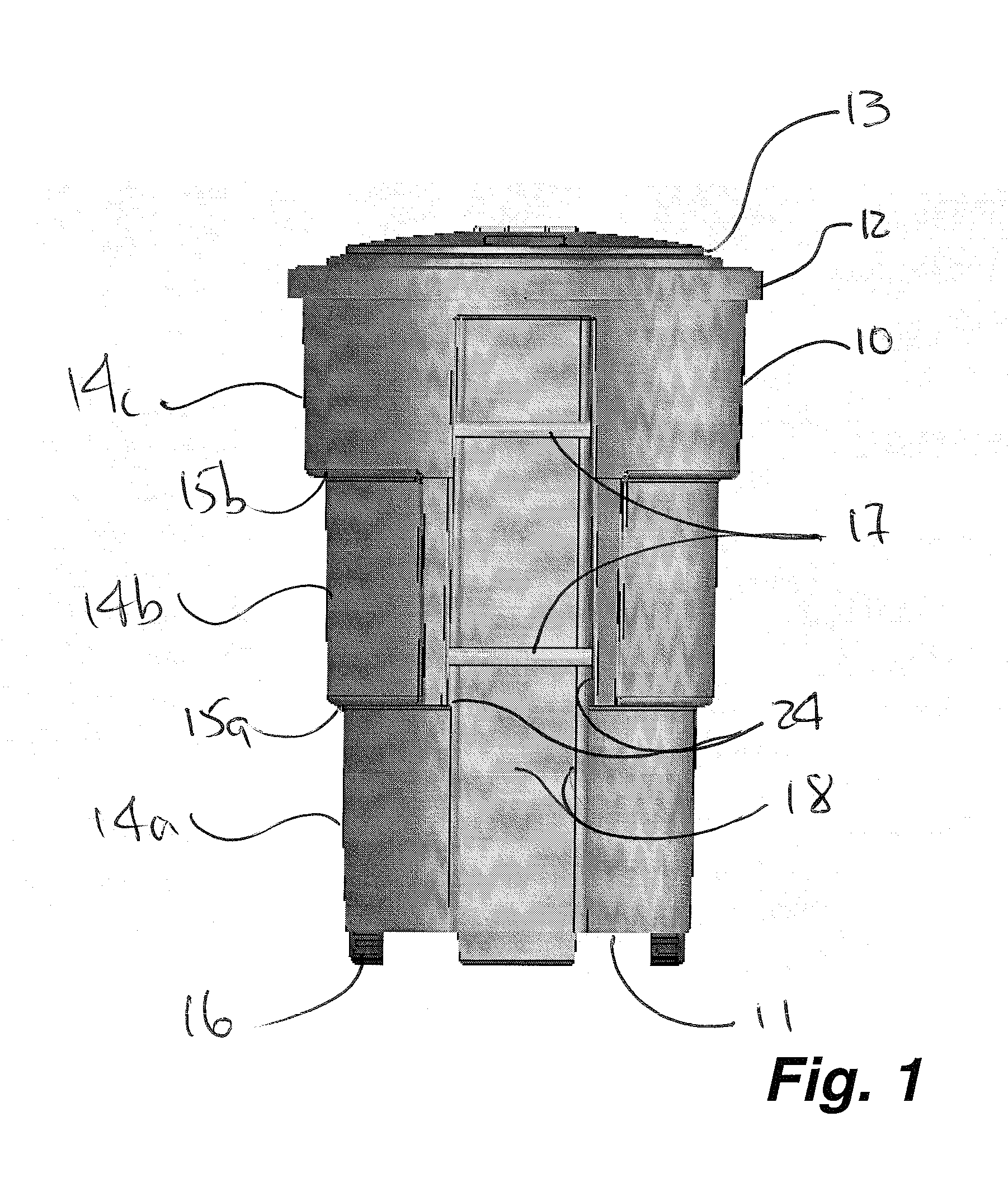

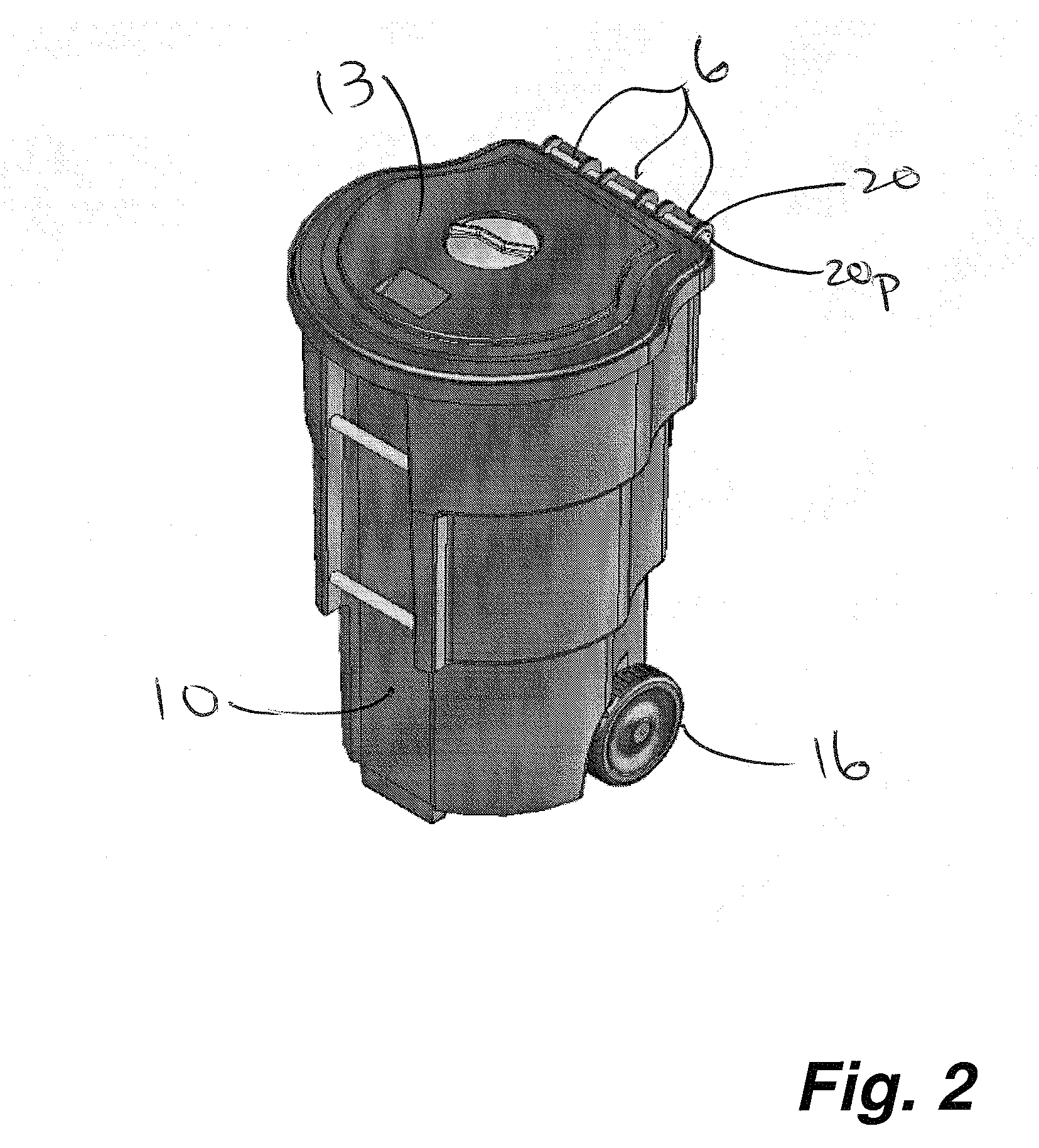

[0035] With reference to FIGS. 1-6, an animal-resistant trash container or bin 10 is a generally cylindrical vessel having a closed bottom 11 and an open top edge 12 fit with a lid 13 which can be manipulated between an open position (FIGS. 4, 5 and 6) to access the bin and a closed position (FIGS. 1, 2 and 3) to close the top edge 12 and restrict access to the bin 10. The lid 13 and top edge 12 are constructed to resist deformation under normal deformation forces. The bin 10 need not be generally cylindrical however the shape may be dictated by methods of manufacture, economics or aesthetics.

[0036] With reference to FIG. 1, the bin 10 is preferably formed of resilient materials such as plastic including high density polyethylene (HDPE) and has a stepped structure for providing rigidity, such as three cylindrical and stacked sections 14a, 14b, 14c as shown connected continuously though annular portions 15a, 15b. With reference also to FIG. 2, typically the bin 10 is also fit with w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com