Method and apparatus for processing fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] An exemplary embodiment of the present invention resides in its use for the processing of a fluid by means of silver ion disinfection for the disinfection of a flowing fluid in conjunction with making use of the benefit of the plating out properties of silver ions to the surface of a fluid carrier comprising, for example, a body in the form of a chamber for fluid flow.

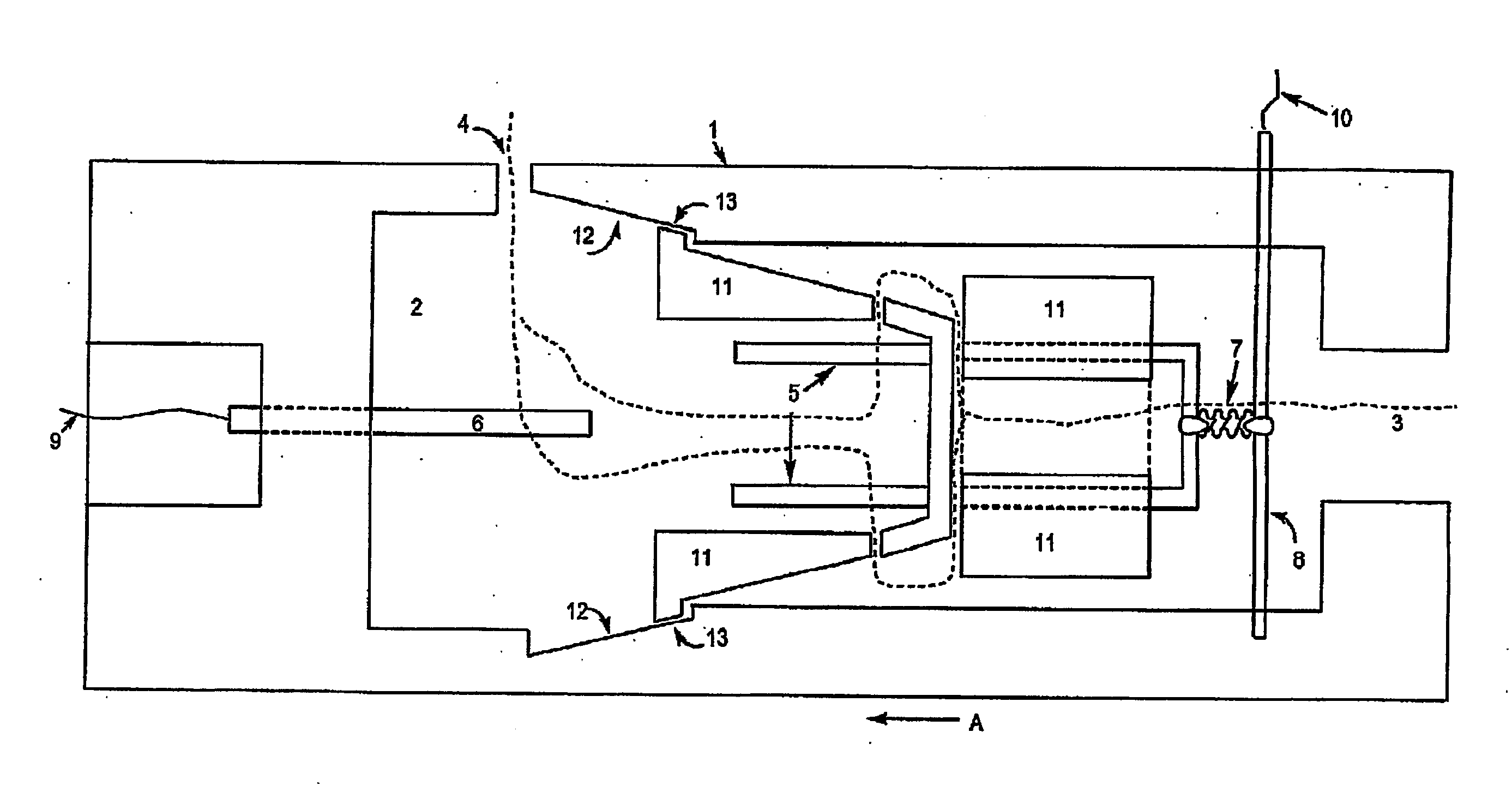

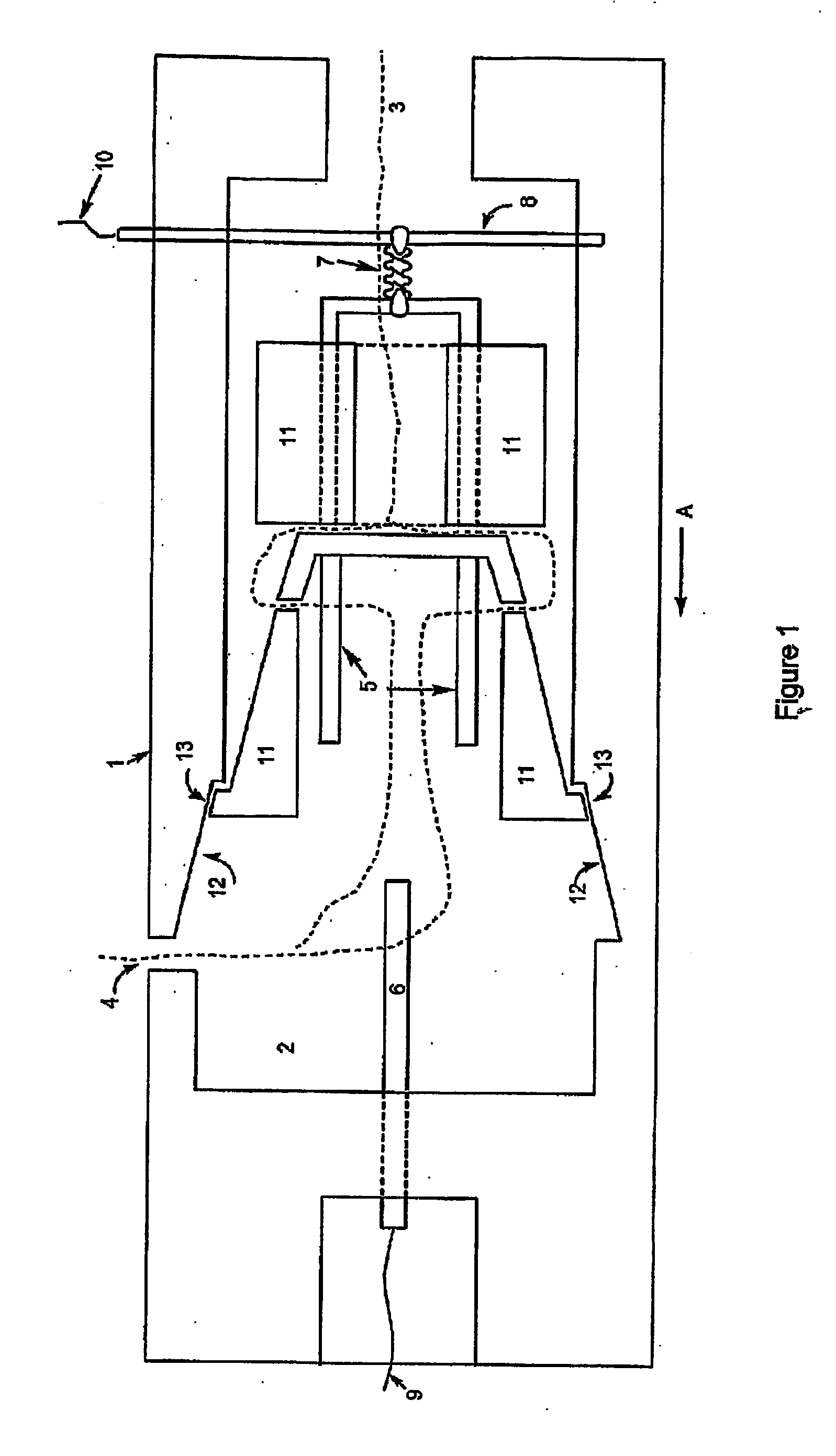

[0035] Referring to FIG. 1, a fluid processing unit is shown generally as 1. The fluid processing unit 1 may be an ion disinfection apparatus or equally, a fluid flow determination apparatus and is defined by a body having a chamber 2 formed with a spaced inlet 3 and an outlet 4 respectively at opposite ends of the chamber 2. The outlet 4, or possibly more than one outlet, may be situated so as to breach the wall of chamber 2 whereby the fluid may be caused to flow from inlet 3 to outlet 4. Within the unit 1 shown in FIG. 1, the first electrode arrangement comprises a single silver electrode 6 and the second el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flow rate | aaaaa | aaaaa |

| Current | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com