Die casting in investment mold

a technology of investment casting and mold cavity, which is applied in the field of investment casting of metals and alloys, can solve the problems of low casting yield, low cost and low yield of investment casting of complex shaped components of such titanium based materials, and difficult filling of thin wall mold cavity regions having a thickness of less than 0.050-0.060 inch,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

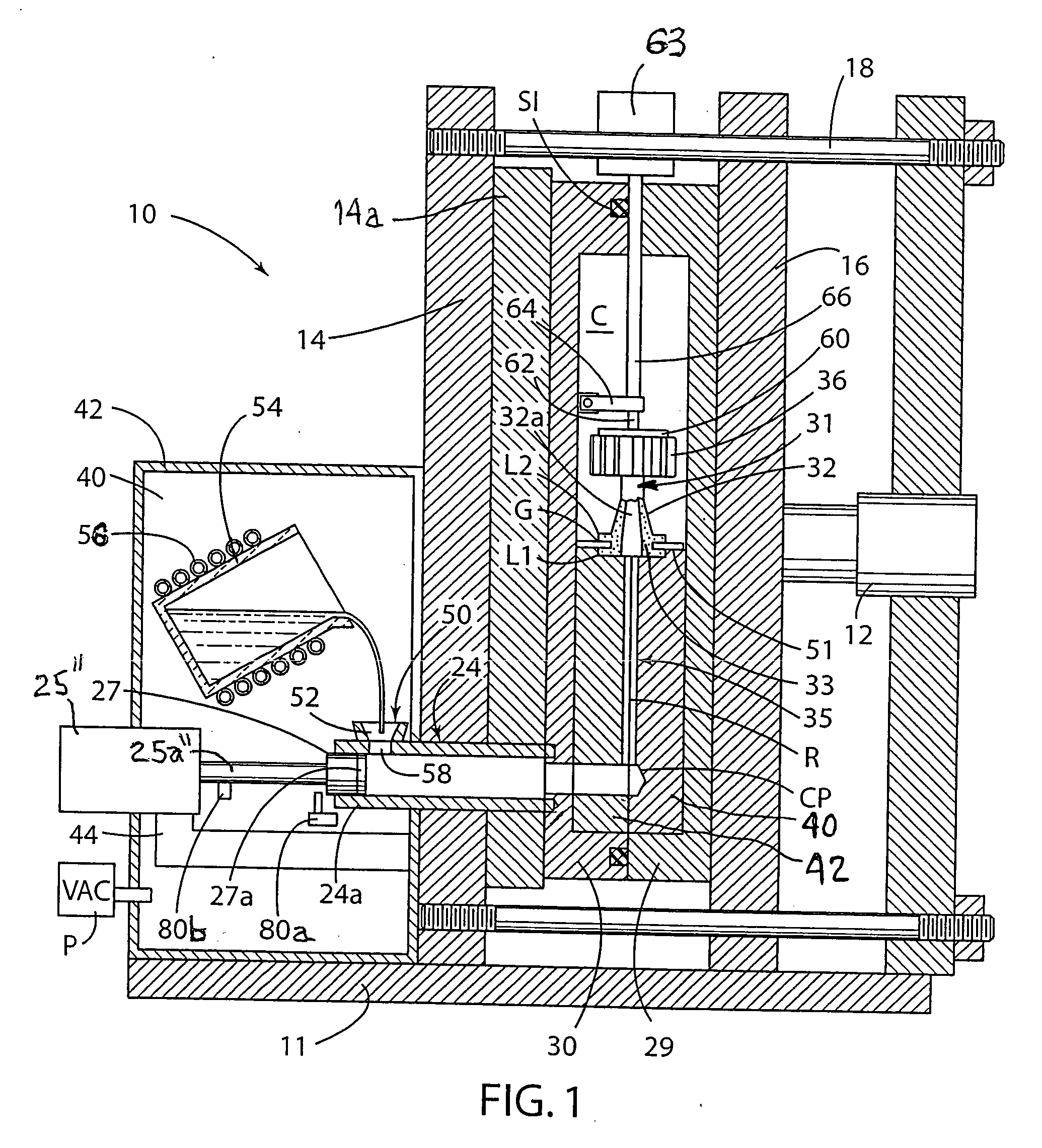

[0078] Turbocharger wheels have been successfully die cast of titanium and titanium aluminide (TiAl) alloys in conventional lost wax investment shell molds 31 by practice of the invention. In general, the turbocharger wheels were made using casting parameters in the following ranges: melt injection pressure settings: 400-1800 psi, melt injection velocities (plunger speed): 10-120 in / sec, melt superheat: 0 to 75 degrees F., mold preheat: room temperature to 600 degrees F., lost wax investment shell mold wall thickness: 0.20 to 1.0 inch, shot sleeve length and diameter: 17.38 inches and 2.80 inches; and limit switch 80a set to dump plunger fluid pressure when the plunger 27 is about 0.75 inch from its final injection position.

[0079] Although the mold 31 is illustrated above for making cast turbocharger wheels, the invention is not so limited and can practiced to make other components that include, but are not limited to, internal combustion engine valves, automotive or truck turbocha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com