Artificial stone anchoring system and method

a technology of anchoring system and artificial stone, which is applied in the field of artificial stone, can solve the problems of damage to cement and joints, stone to gravitate, and it is not possible to construct a wall outdoors using such cement and stones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

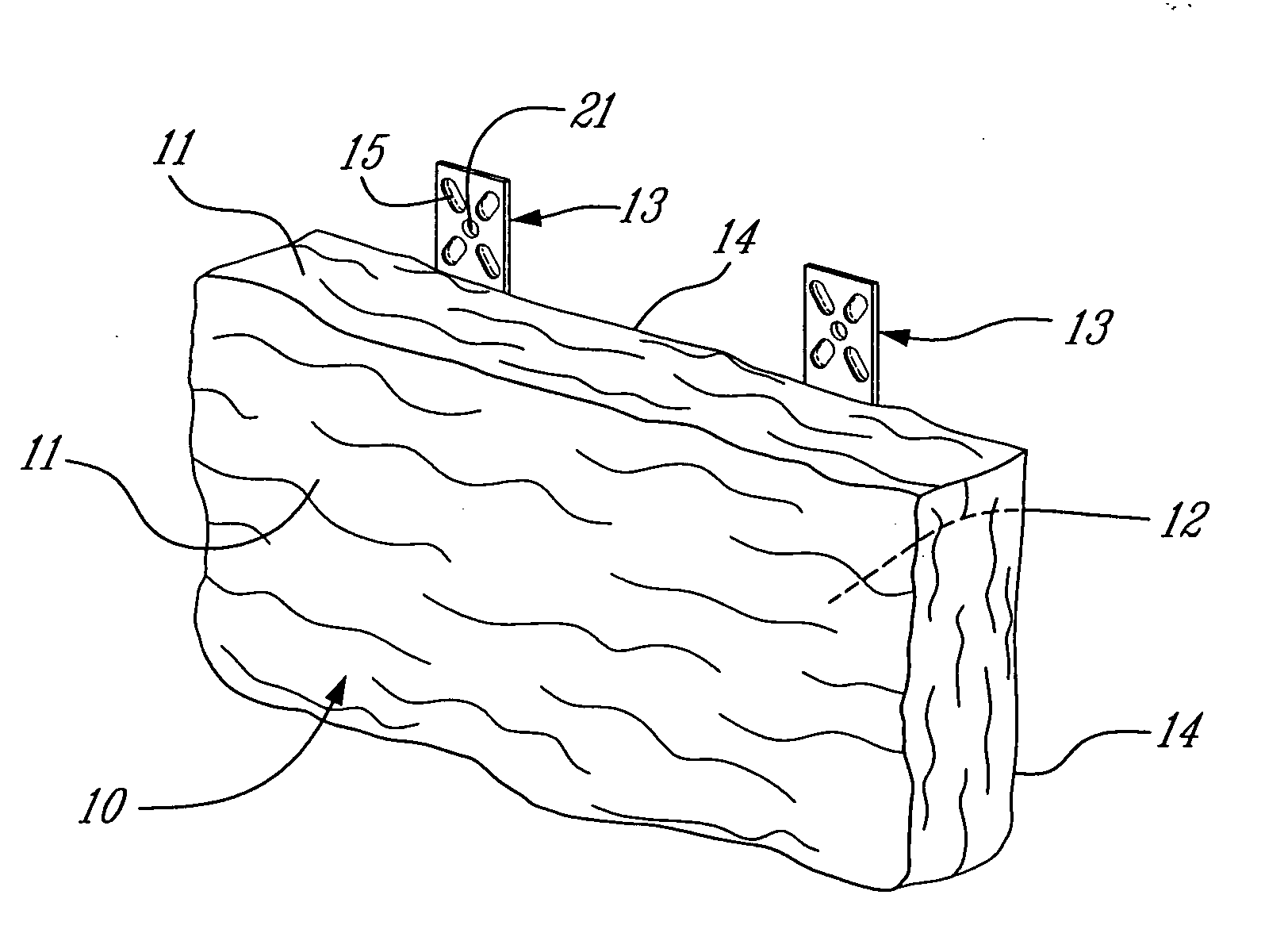

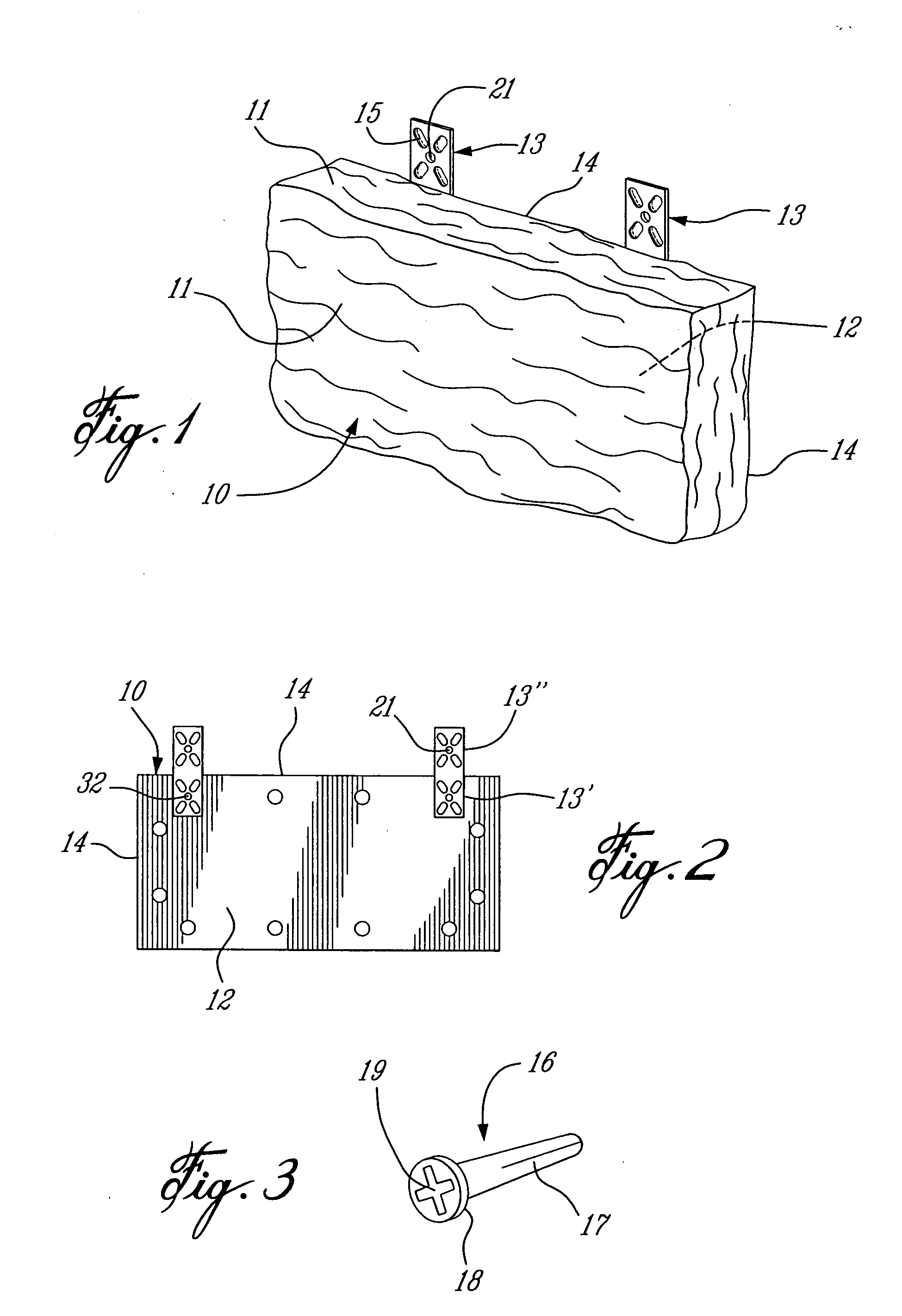

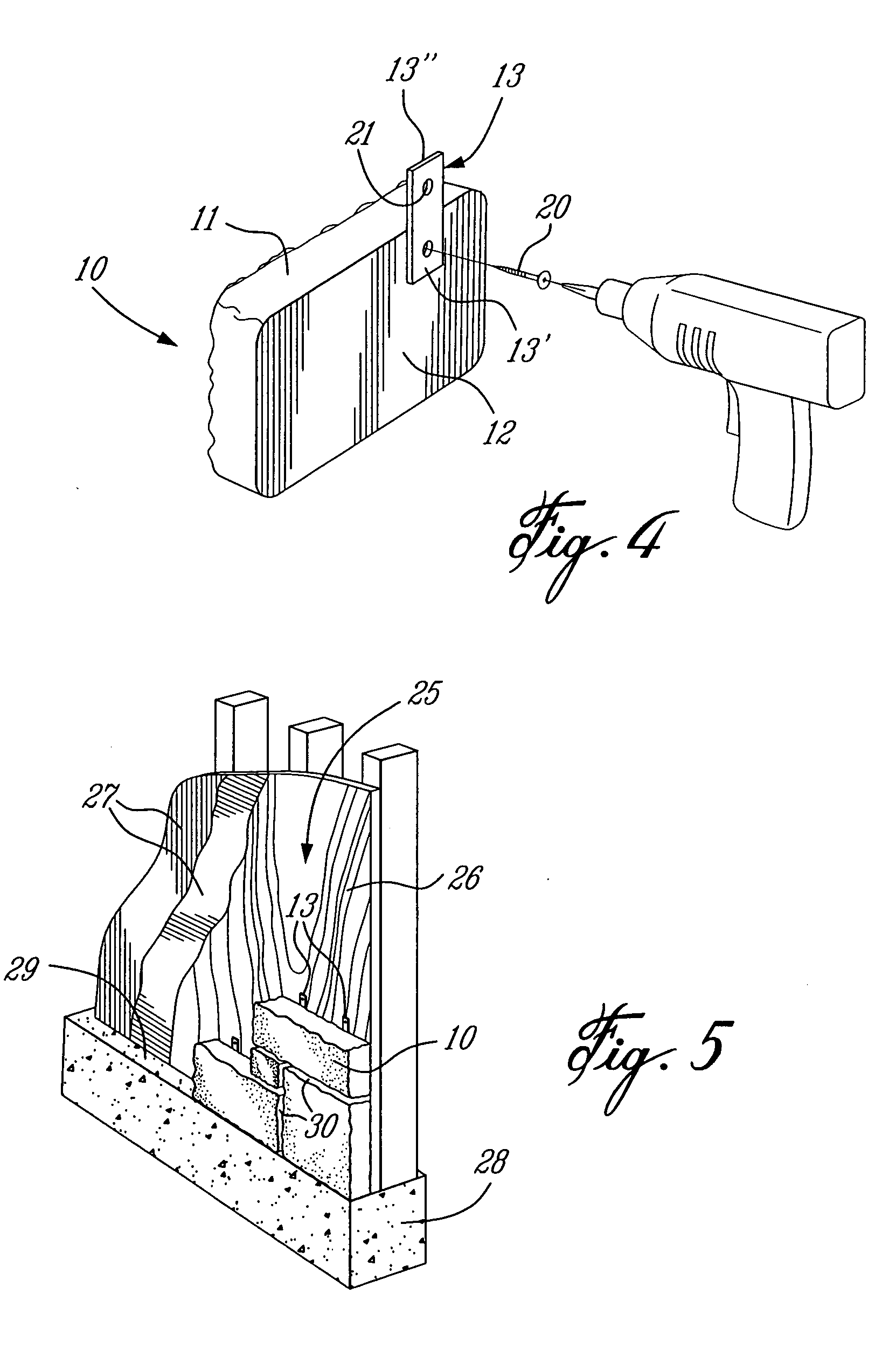

[0020] Referring now to the drawings and more particularly to FIGS. 1 to 3 there is shown an artificial stone 10 which comprises a stone body cast of a cement aggregate and having an outer visible surface area 11 extending in the front and sidewalls thereof which are shaped irregularly to resemble a real stone. The stone 10 is cast in a rubber mold formed from a real stone. A colored pigment is also incorporated in the aggregate or applied to the stone surface area 11 after casting. This stone body has a substantially flat rear surface 12 and one or more attachment brackets, herein two brackets 13, are secured to the rear flat surface 12 adjacent at least one edge 14 of the stone and project outwardly thereof.

[0021] The attachment bracket 13 is herein constituted by a flat metal strip capable of supporting the weight of the cast stone body. The bracket 13 is of rectangular outline and has a length sufficient to permit a lower section 13′ thereof to be secured on the rear surface 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com