Pure acrylic artificial stone as well as manufacturing method thereof

An acrylic and artificial stone technology, applied in the field of pure acrylic artificial stone and its manufacturing, can solve the problems of reducing appearance, feel, weather resistance, heat resistance, water resistance, etc., and achieve excellent thickening performance, excellent appearance and performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

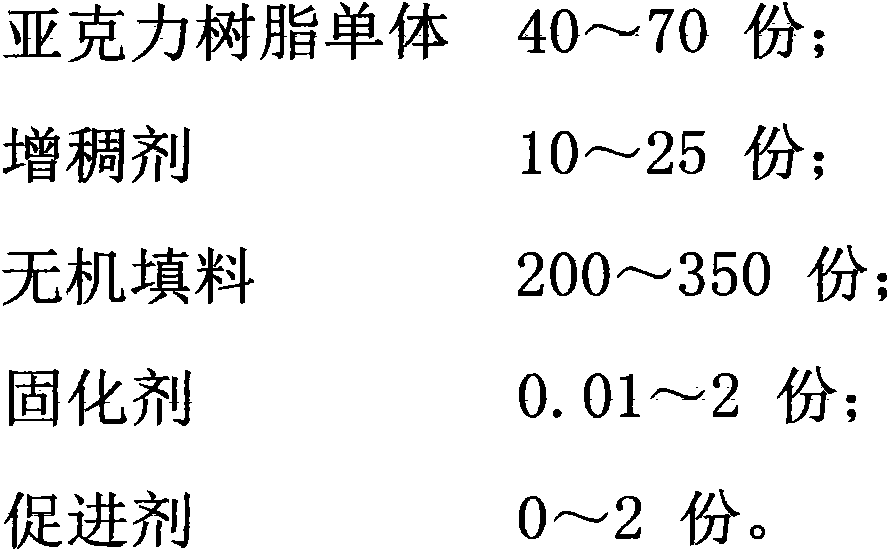

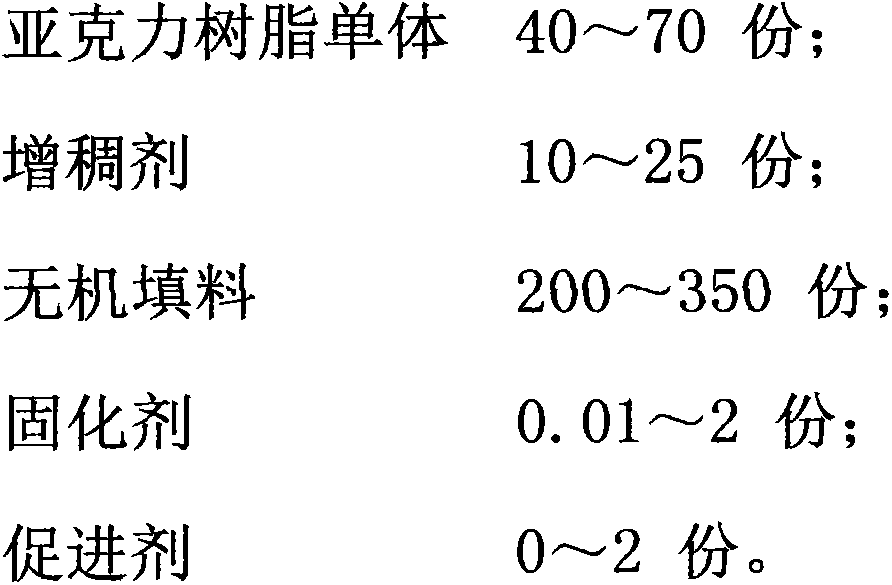

Method used

Image

Examples

Embodiment 1

[0029] Preparation of thickener:

[0030] Add 400 parts of polymethyl methacrylate (molecular weight: 100,000) and 12,000 parts of methyl methacrylate into a stirred tank equipped with a heating device and a cooling device, and heat to dissolve to prepare thickener a.

[0031] Preparation of acrylic artificial stone:

[0032] Add 30 parts of methyl methacrylate, 10 parts of isobornyl methacrylate, 15 parts of neopentyl glycol dimethacrylate into the kneader as the acrylic resin monomer mixture, 25 parts of the thickener a prepared above , 320 parts of inorganic filler aluminum hydroxide, 0.8 parts of curing agent TBPB, 0.1 part of curing agent t-butyl peroxide maleic anhydride, knead the above raw materials for 10 minutes to obtain an acrylic molding compound. The molding compound was placed in an oven at 60°C, and it was not sticky even immediately after kneading.

[0033] Then, the molding compound was filled into a 20CM flat mold, and cured for 10 minutes at a male mold t...

Embodiment 2

[0036] Preparation of thickener:

[0037] Add 400 parts of polymethyl methacrylate (molecular weight 300,000) and 12,000 parts of methyl methacrylate into a stirred tank equipped with a heating device and a cooling device, heat and dissolve to make thickener b.

[0038] Preparation of acrylic artificial stone:

[0039] Add 20 parts of methyl methacrylate, 20 parts of isobornyl methacrylate, 30 parts of neopentyl glycol dimethacrylate into the kneader as the acrylic resin monomer mixture, 15 parts of the thickener b prepared above , 320 parts of inorganic filler aluminum hydroxide, 0.9 parts of curing agent TBPB, 0.1 part of curing agent t-butyl peroxide maleic anhydride, knead the above raw materials for 10 minutes to obtain an acrylic molding compound. The molding compound was placed in an oven at 60°C, and it was not sticky even immediately after kneading.

[0040] Then, the molding compound was filled into a 20CM flat mold, and cured for 10 minutes at a male mold temperat...

Embodiment 3

[0043] Preparation of thickener:

[0044] Add 400 parts of polymethyl methacrylate (molecular weight 300,000) and 12,000 parts of methyl methacrylate into a stirred tank equipped with a heating device and a cooling device, heat and dissolve to make thickener b.

[0045] Preparation of acrylic artificial stone:

[0046] Add 20 parts of methyl methacrylate, 20 parts of isobornyl methacrylate, 20 parts of neopentyl glycol dimethacrylate, 10 parts of 2,2,4_trimethyl_dimethacrylate into the kneader 1,3-pentanediol ester as acrylic resin monomer mixture, 15 parts of thickener b prepared above, 320 parts of inorganic filler aluminum hydroxide, 0.9 part of curing agent TBPB, 0.1 part of curing agent cis-butyl peroxide tert-butyl olefinic anhydride, 30 parts of inorganic filler and acrylic resin particles, kneading the above raw materials for 10 minutes to obtain an acrylic molding compound. The molding compound was placed in an oven at 60°C, and it was not sticky even immediately af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com