Food surface sanitation tunnel

a technology for sanitation tunnels and food surfaces, applied in the field of food surface sanitation tunnels, can solve the problems of increasing the number of people made ill each year, reducing the cost of applying, increasing competition between processors, etc., and achieves the effects of improving the efficiency of the formation of sanitizing plasma, and convenient assembly, transportation, and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

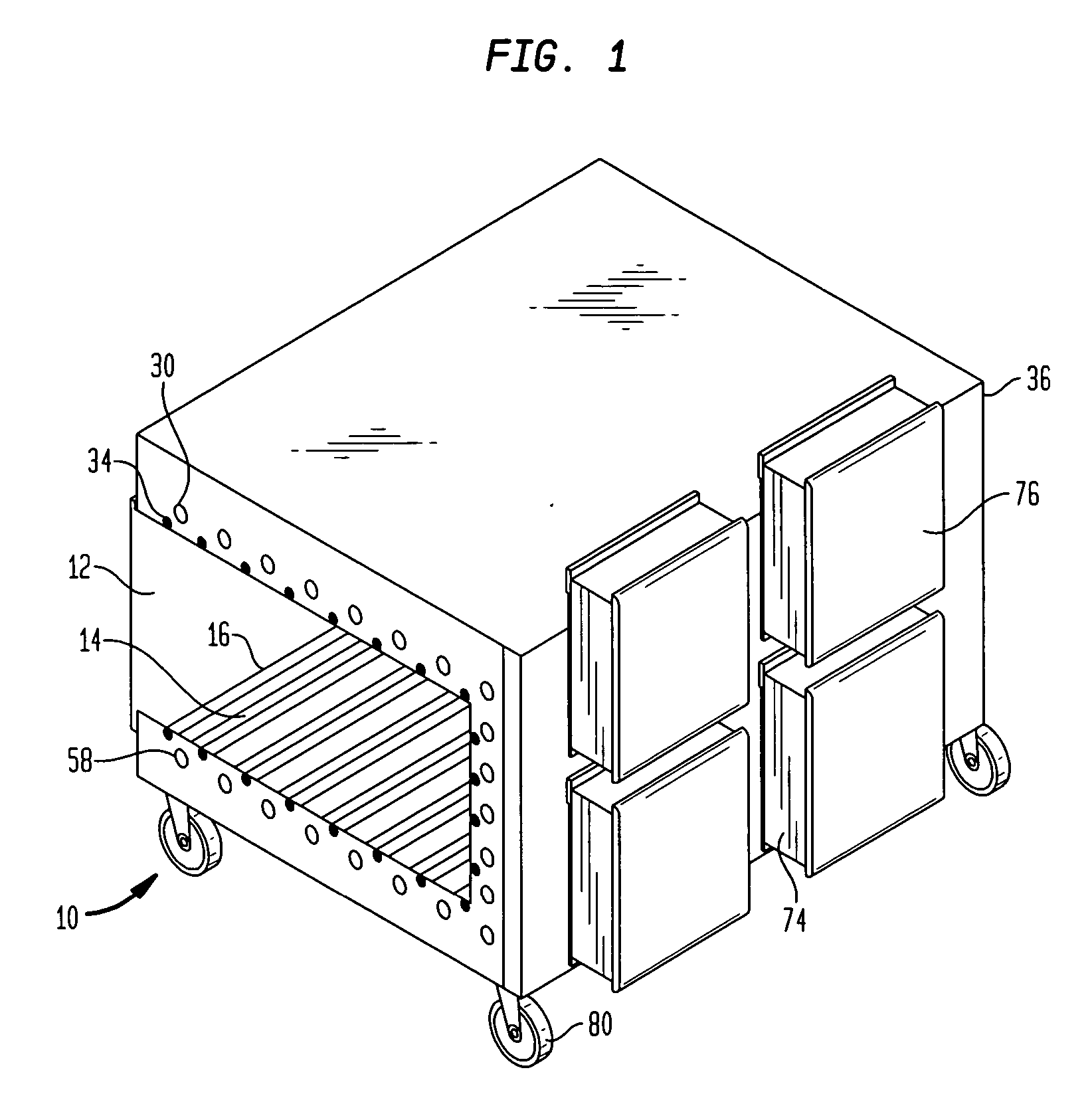

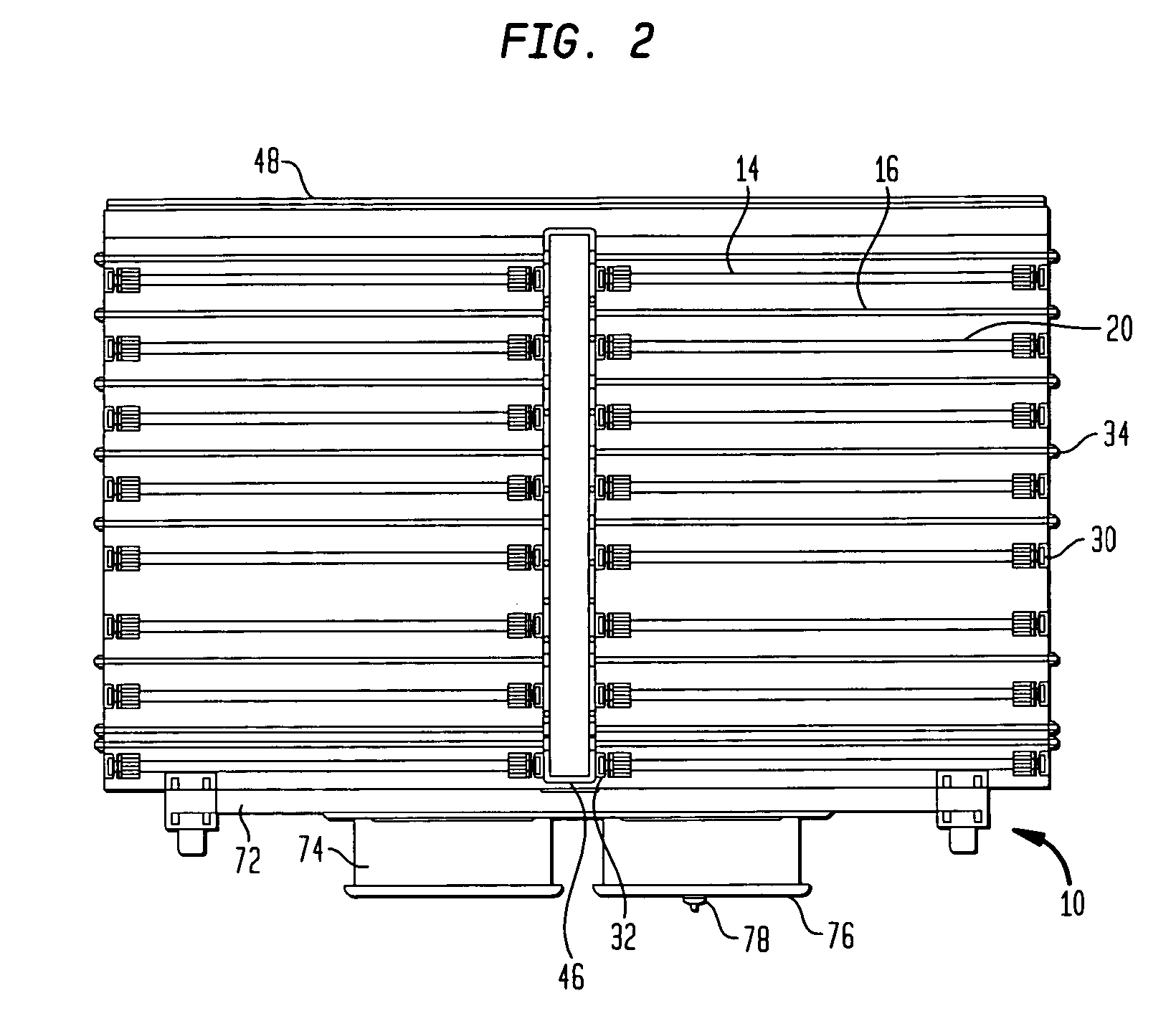

[0057] The present invention is a modular, adjustable, portable, easy to maintain food sanitation tunnel system, shown generally in FIGS. 1-4 at 10. The system includes an enclosing means of a predetermined geometry, such as a c-shaped tunnel 12 for simultaneously subjecting food on at least two sides to sanitizers including UV light, ozone, and a sanitizing plasma including hydroperoxides, superoxides and hydroxyl radicals. Attached to the inside surface of the tunnel 12 are one or more sanitizing radiation sources, such as UV light sources 14, and one or more target rods 16 that are located within the tunnel 12 in optical proximity to the UV light sources 14.

[0058] Preferably the tunnel 12 is made from a rigid, food safe material, such as stainless steel. The tunnel 12 is placed around the food to be sanitized, so that sanitizers touch the food on at least two sides. It is preferred that the food is passed through the tunnel 12 along a conveyor. Where sanitization of the food com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com