Flat plate heat transfer device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

experimental example

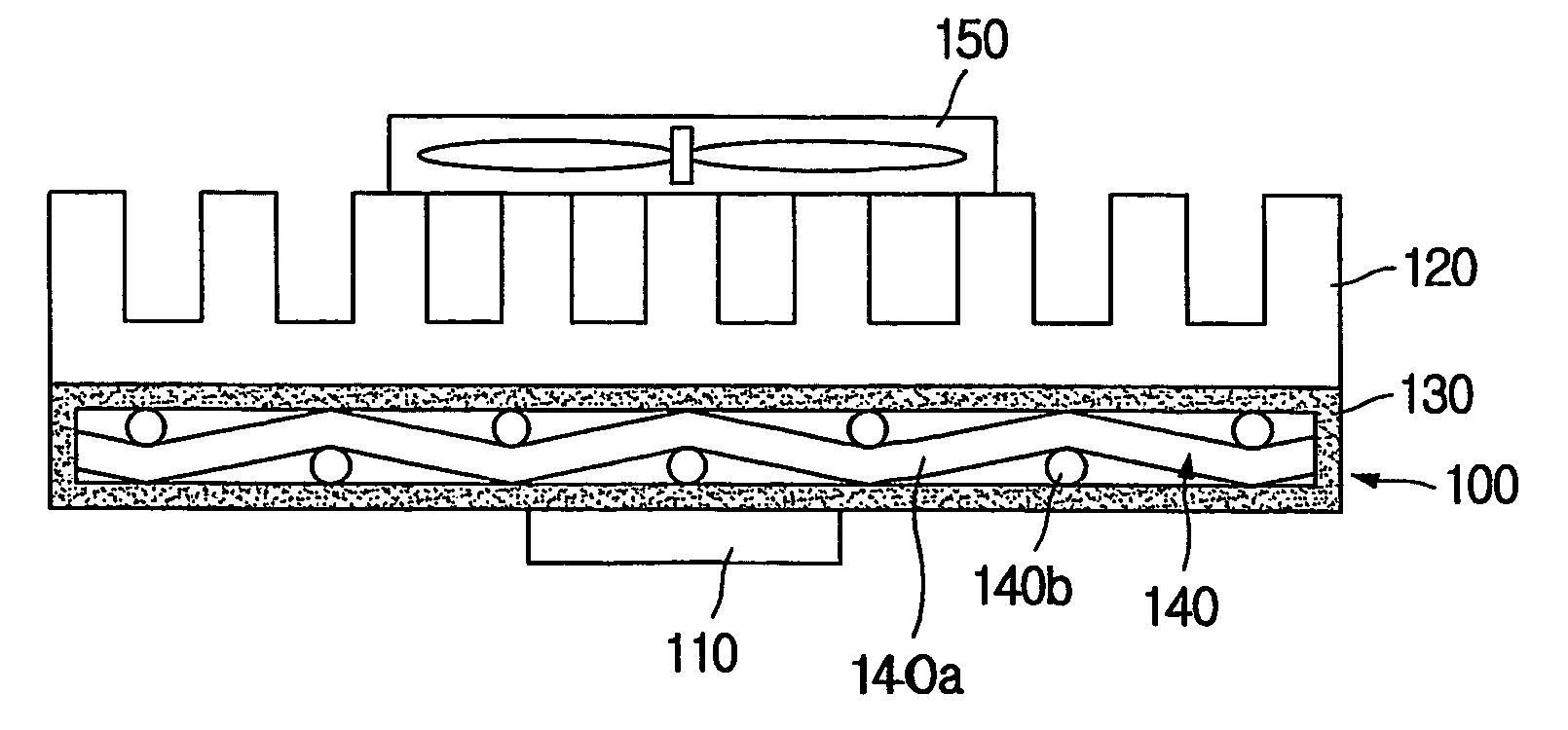

[0049] In order to evaluate the effects of the flat plate heat transfer device according to the present invention, inventors manufactured a flat plate heat transfer device with 40 mm, 70 mm and 0.65 mm in length, width and height. A flat case was composed by associating upper and lower cases separately as shown in FIG. 10, and they were made of a rolled copper foil with a thickness of 0.1 mm. A mesh included in the flat case was a copper screen mesh with a mesh number of 15, a diameter of the mesh wire of 0.20 mm, and a content of copper of 99% or above.

[0050] In order to make the flat plate heat transfer device to be used in this experiment, the screen mesh was positioned between the upper and lower cases so that each case is faced with the screen mesh as shown in FIG. 10, and then the upper and lower cases are sealed using denatured acrylic binary bond manufactured by DENKA in Japan (Trademark: HARDLOC) with a working fluid injection hole left.

[0051] And then, before a working f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com