Building materials from needle-punched fiber mats with granular heat-activated adhesives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

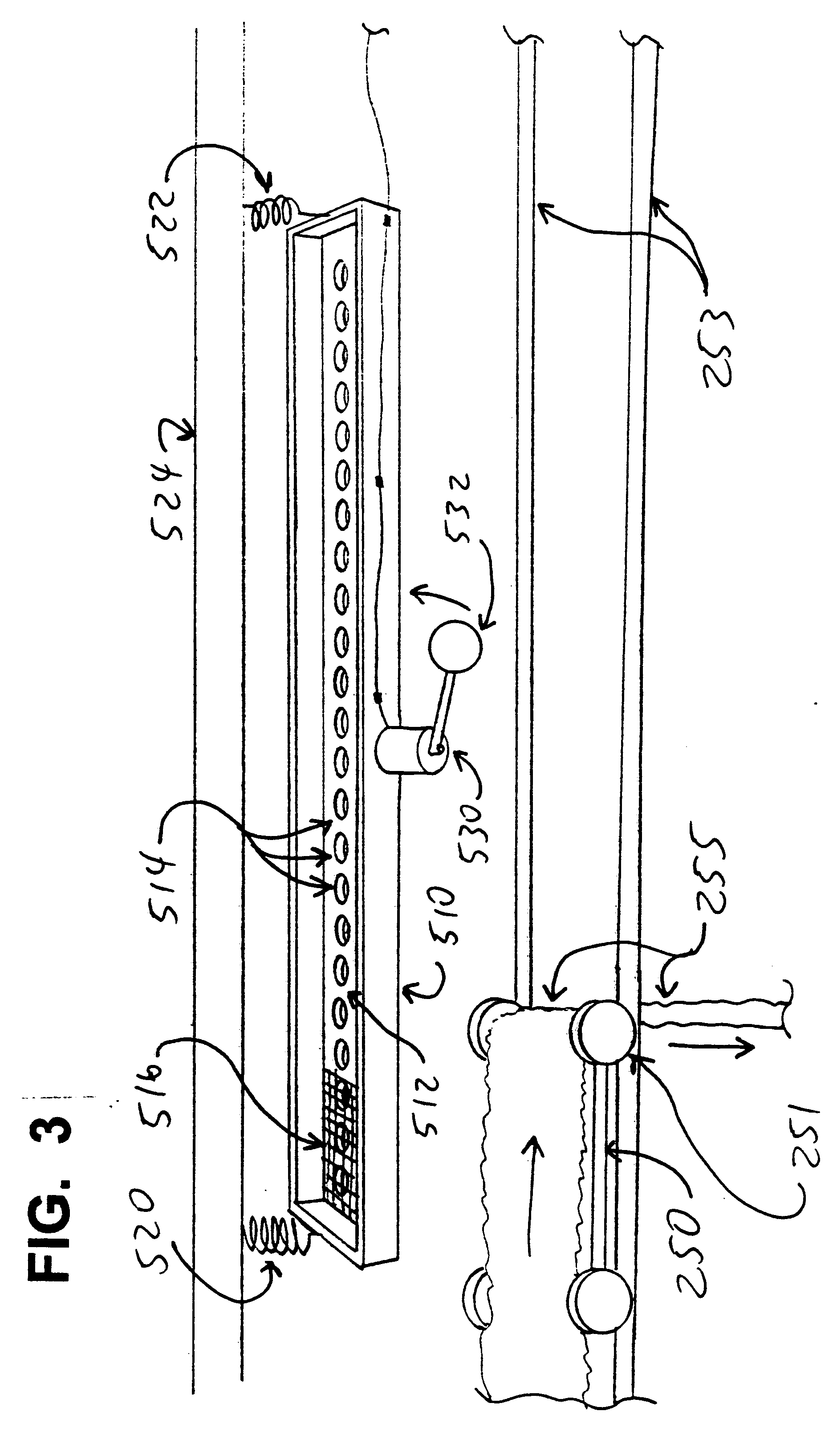

Embodiment Construction

[0034] As summarized above, this invention discloses methods and devices for embedding and distributing particulate adhesives within needle-punched fiber mats. This can allow the use of relatively inexpensive adhesives in the manufacture of various types of building materials (including sheets of wood-like material, comparable to plywood, as disclosed in published PCT application WO 01 / 76869, as well as various other types of building material (such as roofing shingles, embossed layers, laminated beams, etc.) that can be made from recycled carpets or other synthetic fibers.

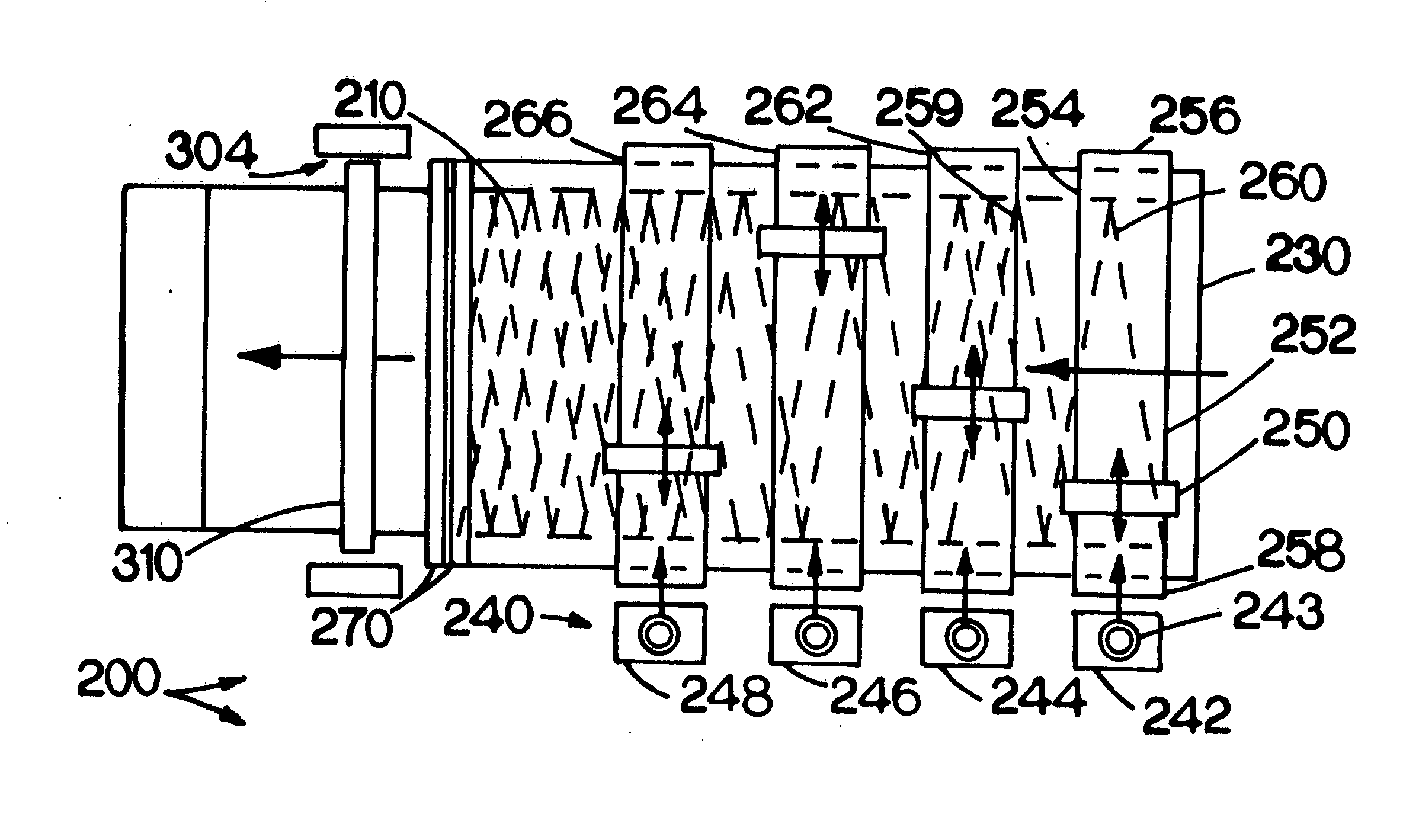

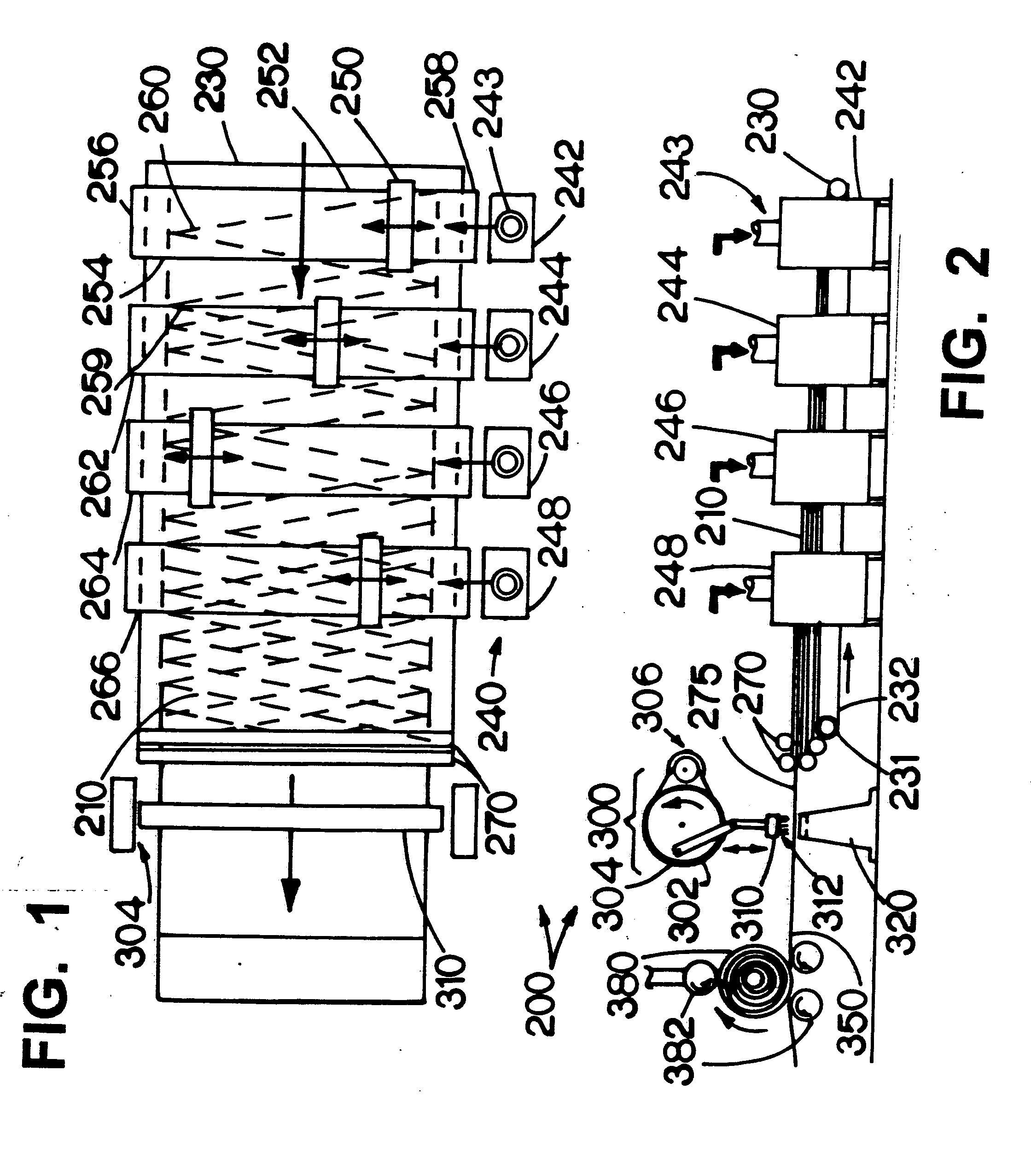

[0035] This manufacturing process uses the same types of cross-lapping and conveyor machines that are used to manufacture conventional needle-punched fiber mats, of the type that are widely used as carpet underlayers in commercial sites such as stores and restaurants. A conventional system of this type, which is prior art, is shown as system 200 in FIG. 1 (a top or plan view) and FIG. 2 (a side or elevation view)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com