Polyester Resins for High-Strength Articles

a polyester resin and high-strength technology, applied in the field of high-strength polyester resins, can solve the problems of insufficient dimensional stability of most high-clarity polyester bottles, inability to efficiently form preforms and bottles, and inability to meet the requirements of dimensional stability, etc., and achieve the effect of efficient formation of low-haze, high-clarity articles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

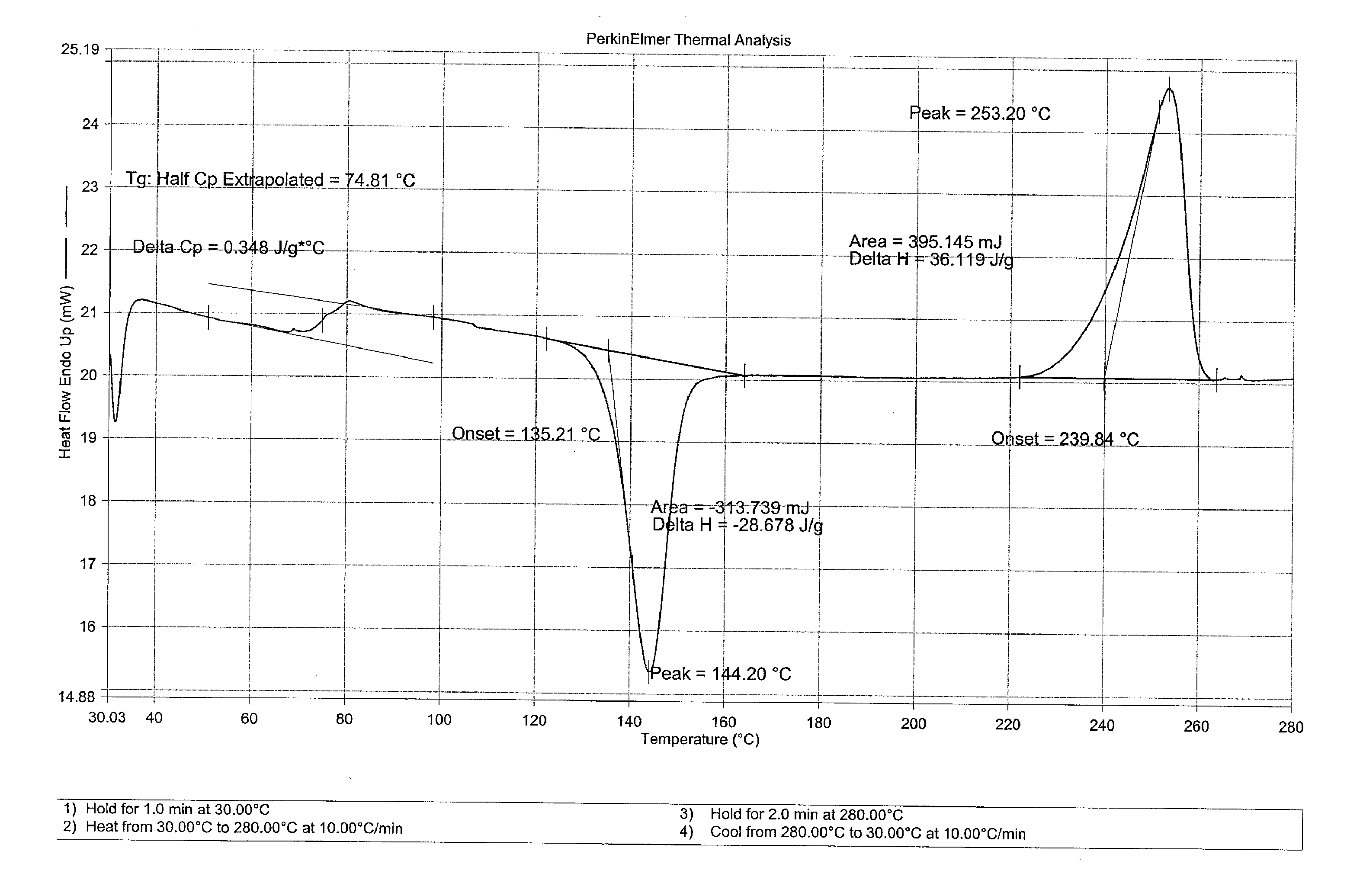

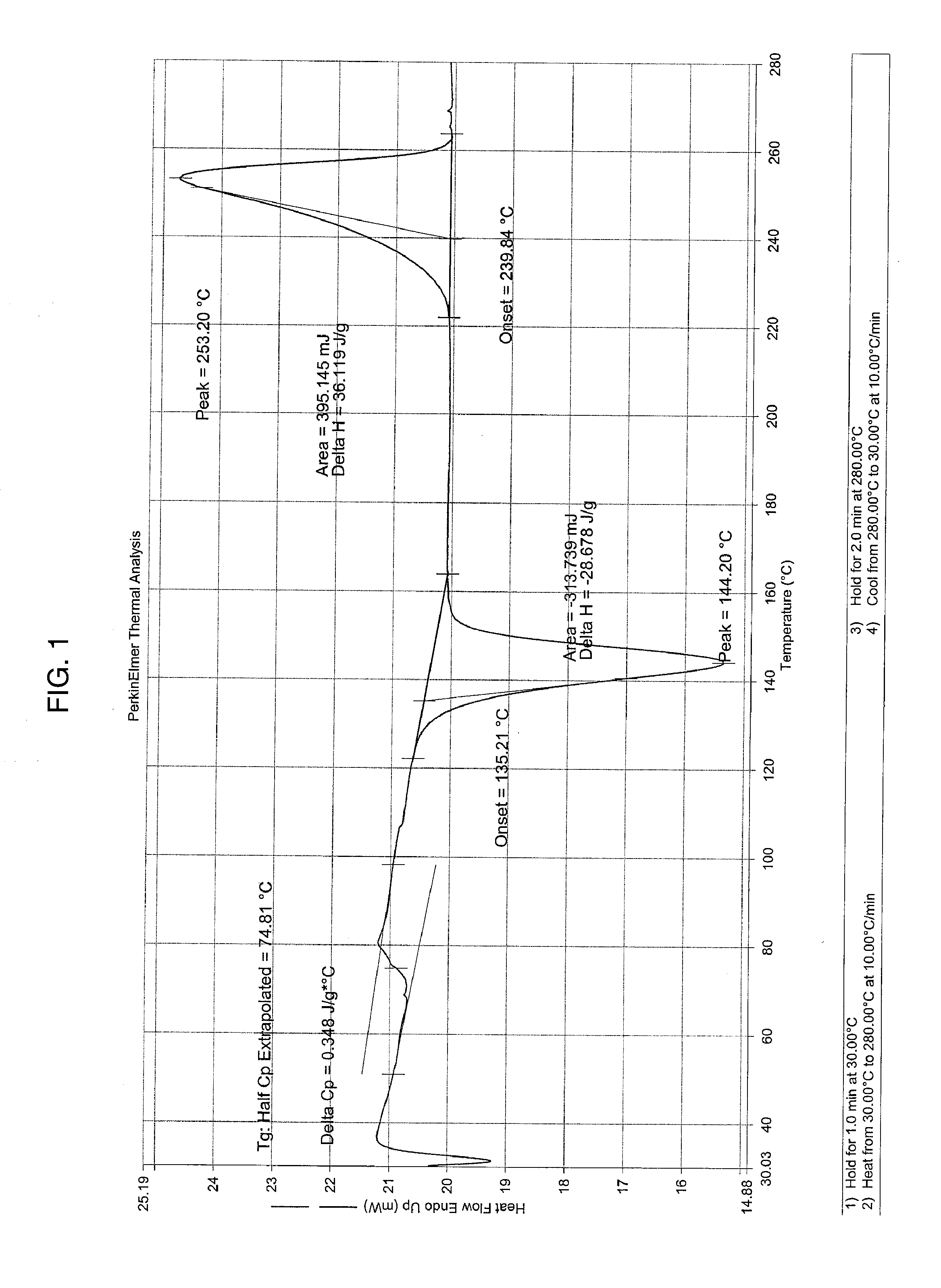

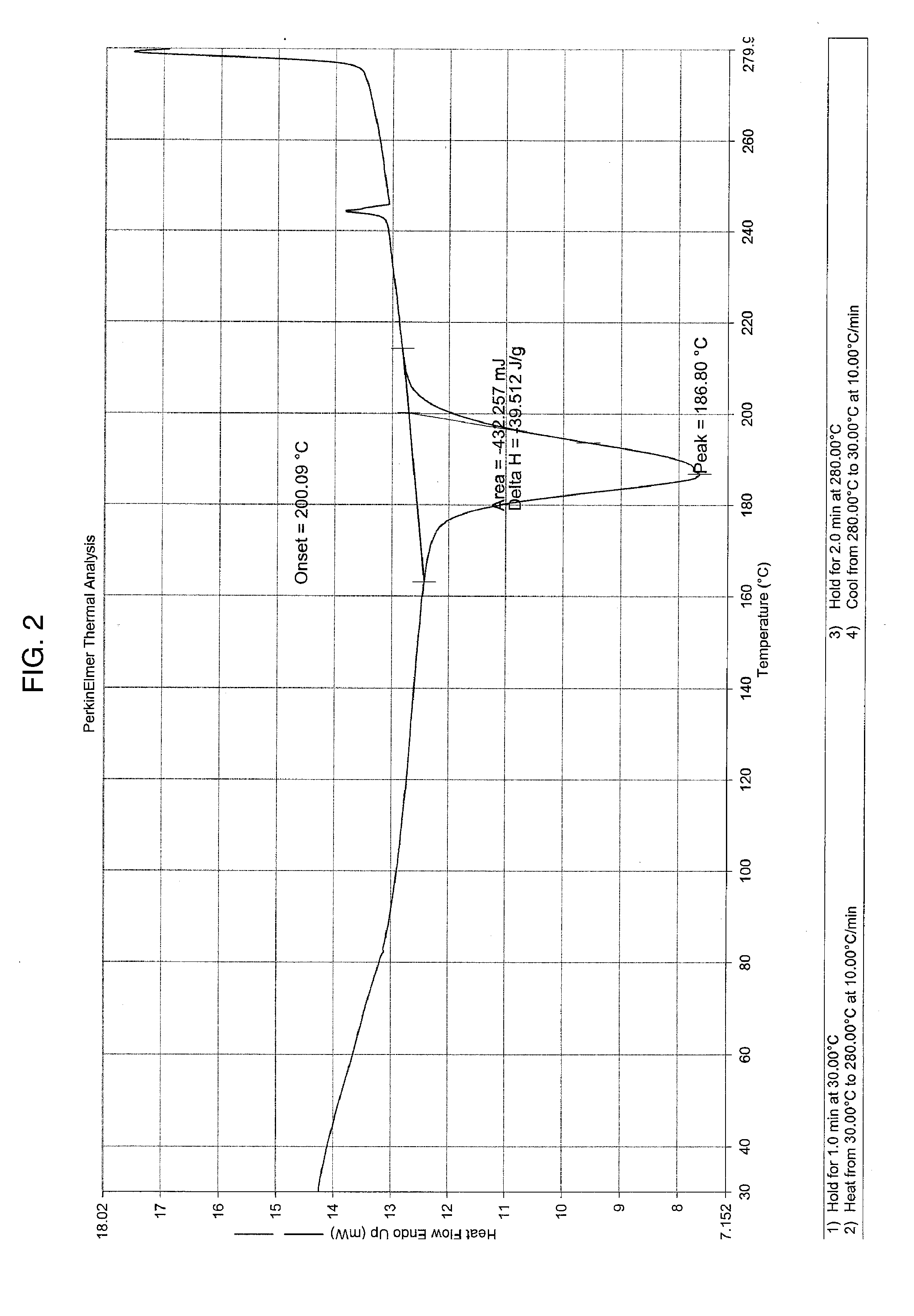

Image

Examples

example 1

[0134] A two-liter polyethylene terephthalate bottle test parison was produced from a standard resin (i.e., Wellman's PermaClear® HP806 polyester resin). This test parison required eight reheat zones for production of a straight-wall, two-liter bottle. At an overall oven power percentage of 80 percent, the reheating profile for this PermaClear® HP806 test parison is shown in Table 1:

TABLE 1Heating ZonesPower output (%)174260355455555668786874

[0135] After establishing this reheating profile, two samples were prepared from an antimony-catalyzed polyethylene terephthalate resin having less than about 6 mole percent comonomer substitution. On sample included about 11 ppm of a carbon-based heat-up rate additive (Resin A) and the other sample, a control, included no heat-up rate additive (Resin B). Besides the presence of a heat-up rate additive, Resin A and Resin B were otherwise identical. The reheat performance (i.e., via surface temperature measurements) for both Resin A and Resin B...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com