Biodegradable resin composition

Inactive Publication Date: 2007-02-22

ELECSYS +1

View PDF9 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

[0014] Also, it is another object of the invention to provide a biodegradable resin composition which can lower the manufacturing costs of the biodegradable resin composition to be produced and prevent environmental contamination in advance by reusing a cause factor inducing environmental contamination and a biodegradable molding using the same.

Problems solved by technology

As plastics are light and strong and they are easy to be processed and not easily degraded, their consumption from industrial materials to disposable products and wrapping materials is continuously increasing.

However, the disposal of wastes by landfill, incineration, etc. gives rise to environmentally severe damage.

However, as the starch is added, a plasticizer is to be added, which causes discoloring and bad fume during processing and the properties of the plastics are remarkably deteriorated.

However, the ethylene-acrylic acid copolymers are expensive and the properties of the produced films are extremely fragile for practical use, and their biodegradability is not good.

However, unreacted coarse monomers are likely to remain, and in the case that the content of the starch is more than 30%, mechanical properties are remarkably reduced, and the polyethylene which is used as a matrix resin is not degraded and remains.

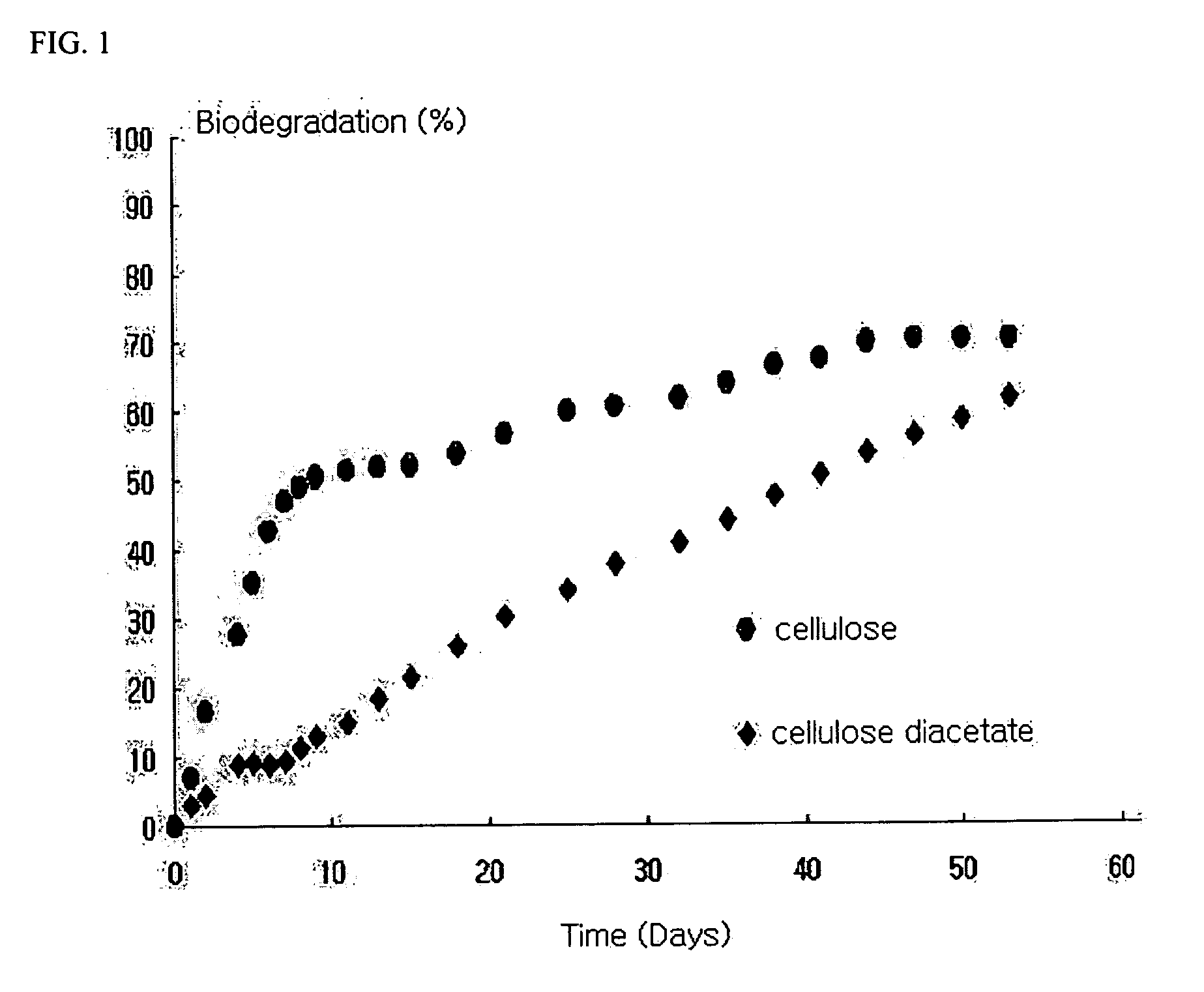

The cellulose acetate, a conversion form into an acetic ester of cellulose, has been known to be inherently biodegradable but in fact, its biodegradability is not good.

Thus, although molding products comprising the cellulose acetate are laid under the grounds, they maintain the prototype of the molding products until 1 or 2 years and it takes considerably long time for the molding products to be completely biodegraded.

However, in this method, at the point when the acid compound is added to the cellulose acetate, the cellulose acetate is chemically hydrolyzed by the influence of the acid compound and this hydrolysis reaction generates acetic acid, which gives strong acetic acid odor to the cellulose acetate products.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1

[0045] After 70 parts by weight of cellulose diacetate having a molecular weight of 202,332 (Eastman Co., Ltd.), and 30 parts by weight of triacetin (Mw. 218.21, major component C9H14O6), Dae Shin Chemical Ind. Co., Ltd.) as a plasticizer were evenly mixed, the mixture was kneaded for 3 hours at the temperature of 100° C. and melted in Haake rheocord system of 200° C. thereby to prepare a blending mixture.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Mass | aaaaa | aaaaa |

Login to View More

Abstract

This invention provides a biodegradable resin composition and a biodegradable molding using the same and in particular, it not only have satisfactory biodegradability, processability and properties required for biodegradable resins by comprising cellulose diacetate as a main component but also can lower manufacturing costs and prevent environmental contamination by preparing the biodegradable resins by reusing a cause factor of environmental contamination.

Description

BACKGROUND OF THE INVENTION [0001] 1. Field of the Invention [0002] The present invention relates to a biodegradable resin composition and a biodegradable molding using the same and more particularly, it relates to a biodegradable resin composition comprising cellulose diacetate as a main component, which can not only satisfy the biodegradability, processability and properties required for a biodegradable resin but also lower manufacturing costs and prevent environmental contamination by producing the biodegradable resin by reusing a cause factor of environmental contamination and a biodegradable molding using the same. [0003] 2. Description of Related Art [0004] As plastics are light and strong and they are easy to be processed and not easily degraded, their consumption from industrial materials to disposable products and wrapping materials is continuously increasing. Hard wastes including such plastics are disposed by landfill or incineration after their use, or reused by recyclin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D21H19/54

CPCC08K5/053C08K5/103C08K5/11C08L1/12C08L97/02C08L101/16C08L2201/06C08L2666/26C08K5/0016B29C45/0001B29C48/022

Inventor YI, YOUNG-KWANLEE, SANG-HWAN

Owner ELECSYS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com