Molded product and manufacturing method thereof

a technology of molded products and manufacturing methods, applied in the direction of solid balls, transportation and packaging, sports equipment, etc., can solve the problems of difficulty in forming an insulating layer not defective between metal bodies, and problems such as problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

(Embodiment 1)

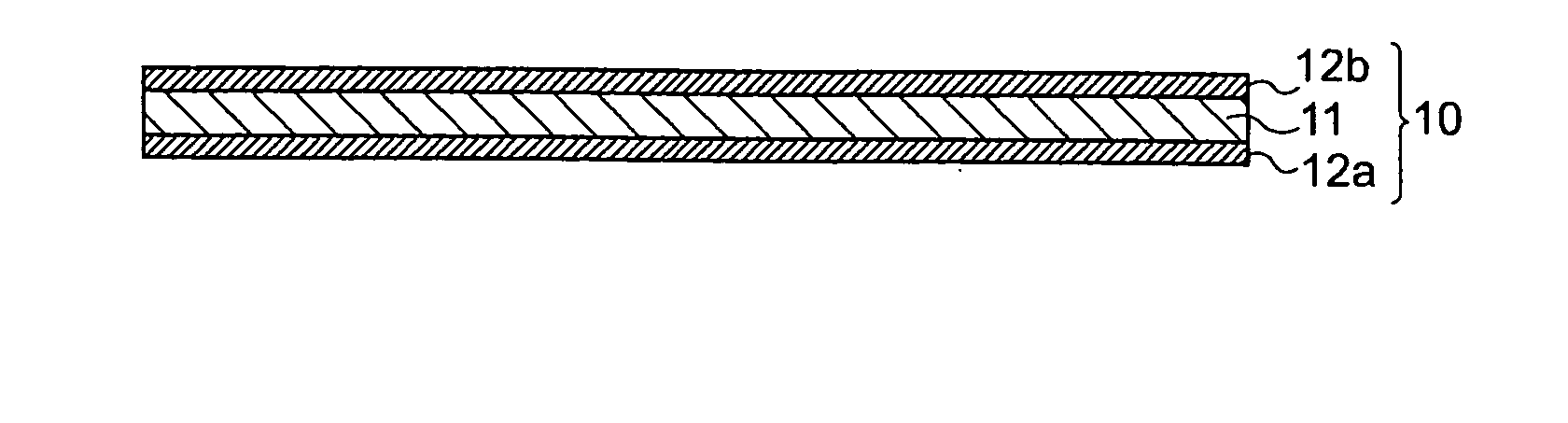

[0066] PPE sheet (Asahi Kasei Corporation, Zairon 540Z, and thickness t is 0.4 mm) where the heat-hardening bonding layer had been spread on both sides as shown in FIG. 1 was prepared. The sheet was cut into the size (220 mm×230 mm) whose length and breadth is 10 mm larger than the lap area of two sheet coppers. Moreover, flame-resistant PE resin sheet (UBE INDUSTRIES, LTD. Z555, and thickness t is 2.5 mm) which the hot melt adhesive layer was spread on one side as shown in FIG. 2 was prepared. The flame-resistant PE resin sheet was cut (220 mm×230 mm×2.5 mm) so that the volume of two flame -resistant PE resin sheet may become more than the value obtained by subtracting the volume of the sheet copper and the PPE sheet from the volume of the molded product of 240 mm×250 mm×5 km. Further, a frame body composed of lower metal frame 81 shown in FIG. 8 and an upper metal frame which makes couple with lower metal frame 81 was prepared.

[0067] The laminate piled up in order o...

embodiment 2

(Embodiment 2)

[0070] The same PPE sheet as embodiment 1 was made. Moreover, injection molding dies 90 shown in FIG. 9 as a frame body was prepared.

[0071] The laminate piled up in order of a sheet copper, a PPE sheet and a sheet copper was placed between hot pressing plates of a hot pressing molding machine, and heated to 130° C. The bonding layer in the PPE sheet melted by this heating processing, and the sheet copper and the PPE sheet were bonded through the bonding layer. The injection molding processing was carried out by injecting the flame-resistant PE resin melted after having arranged this laminate in cavity 93 of injection molding dies 90. Thereby, the molded product (sample 2) which has the structure shown in the FIG. 7 was produced.

[0072] As a result, in sample 2, a very thin and uniform insulating layer (spacer polymer) was formed between sheet coppers of 0.4 mm in the clearance and 200 mm in one side. Partial discharge generation disappearance (10 pC) voltage in sample...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com