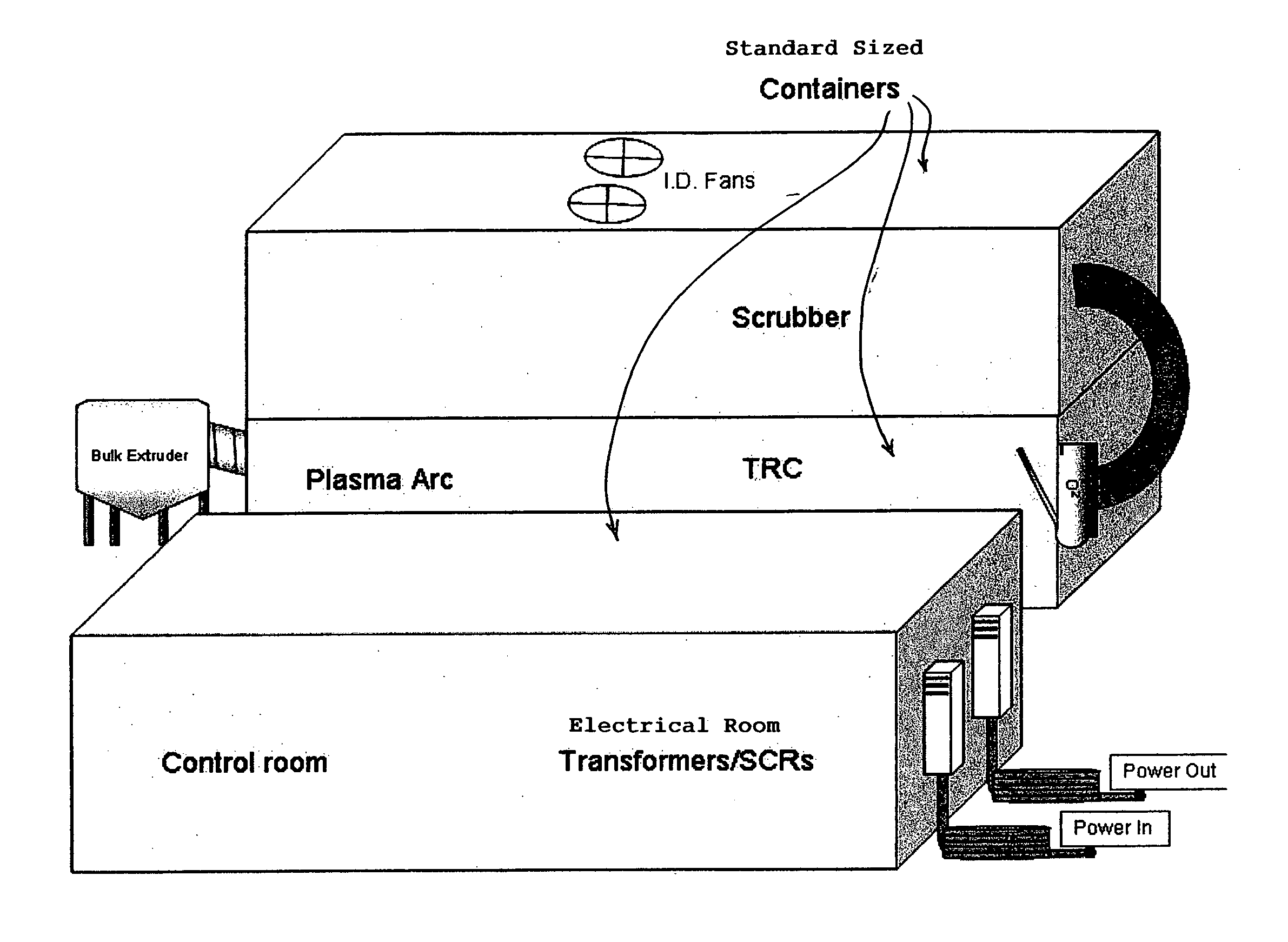

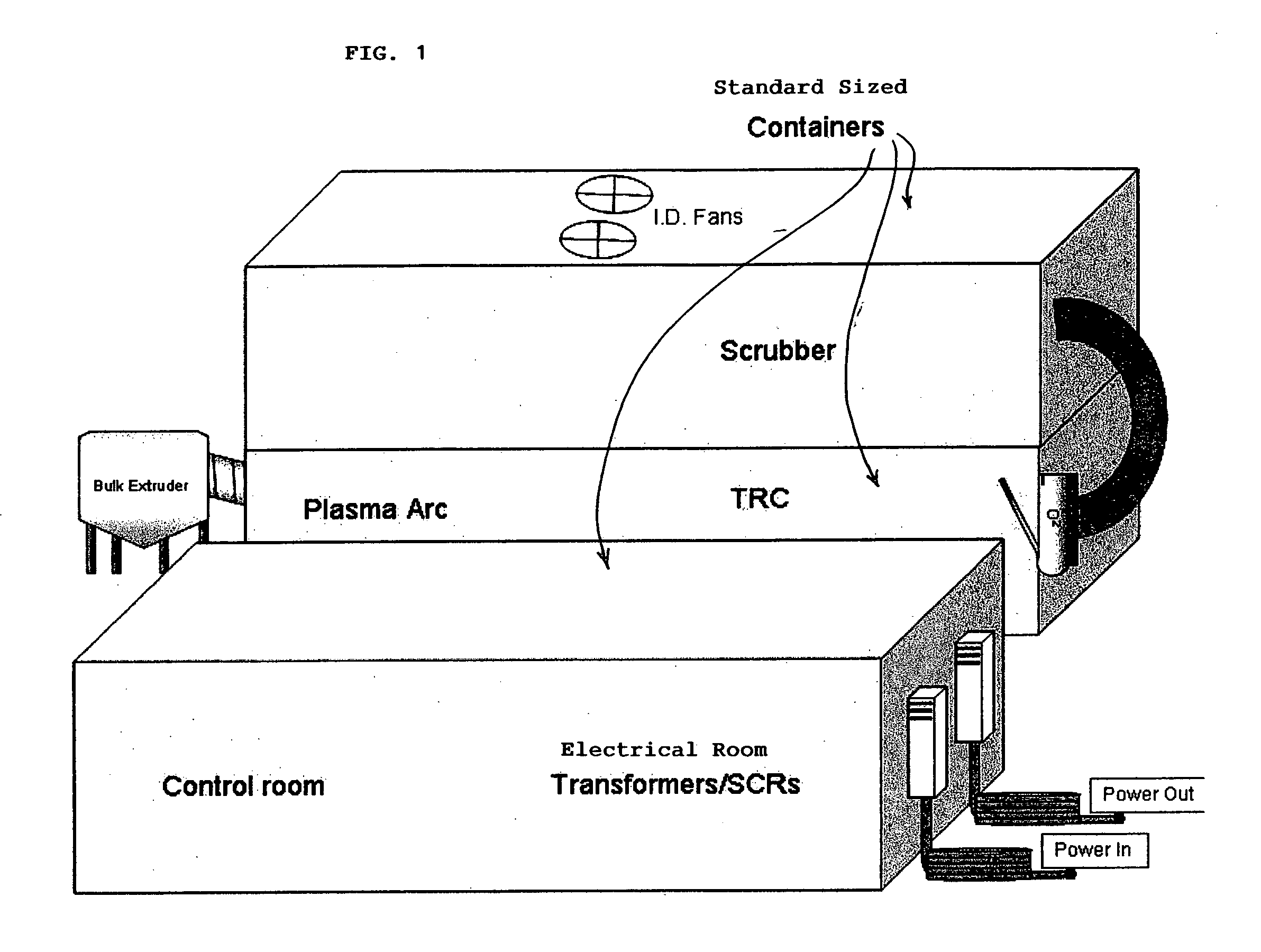

Modular plasma ARC waste vitrification system

a technology of waste vitrification system and plasma arc, which is applied in the direction of incinerator apparatus, combustion types, lighting and heating apparatus, etc., can solve the problems of limiting the usefulness of hazardous waste landfills, increasing the availability of landfills, and imposing additional disposal costs, so as to reduce the deterioration of structural components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

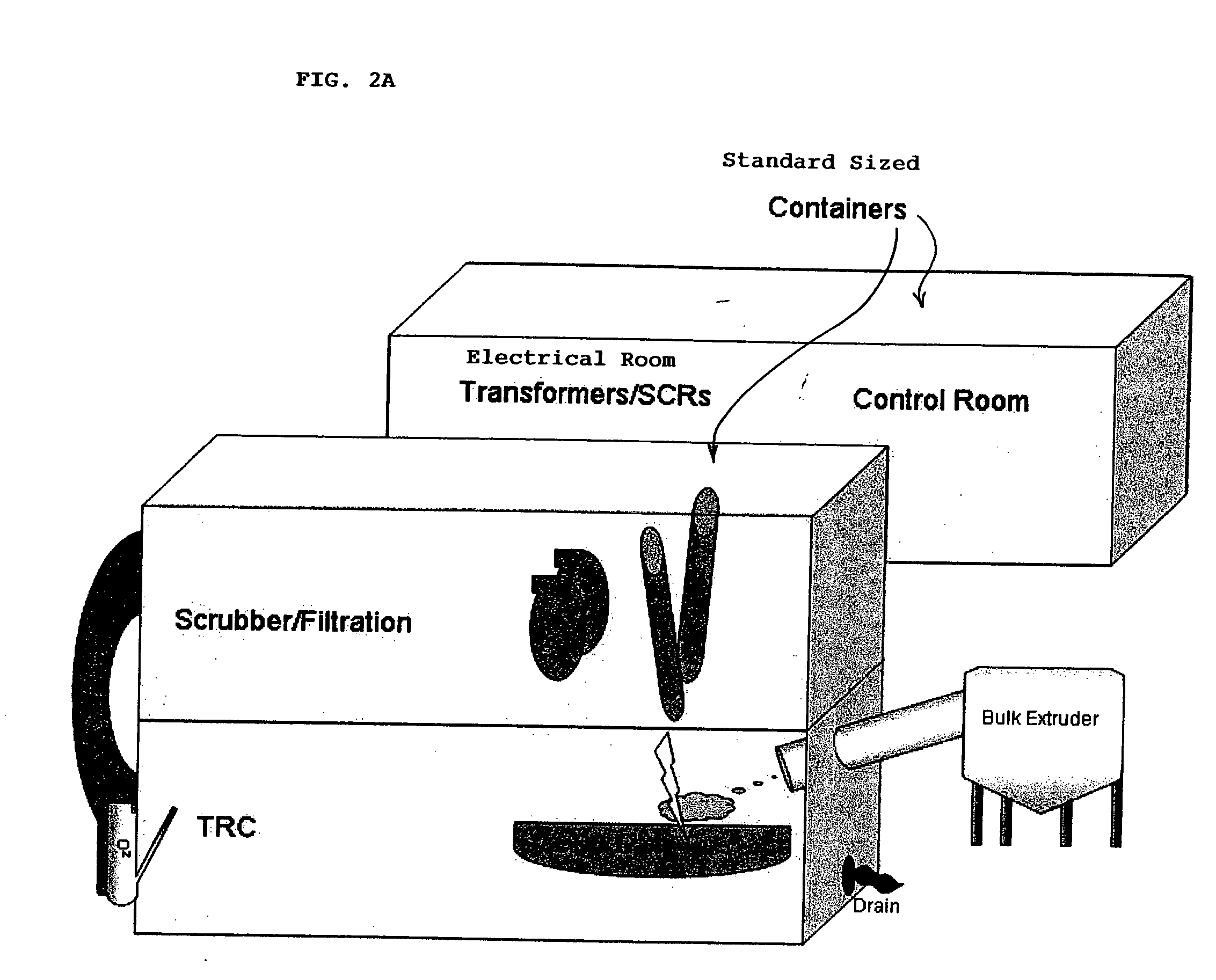

[0026] As a background for description of the invention system, reference is made to a prior art type of plasma arc vitrification system as described in U.S. Pat. No. 5,811,752 issued Dec. 8, 1998 to Titus et al, and to an integrated solid waste processing system preferred for processing biomedical or hazardous waste as described in U.S. Pat. No. 6,766,751 issued Jul. 27, 2004, to the same inventor as this U.S. patent application, which are incorporated by reference herein.

[0027] The general principles of operation of a prior art plasma arc vitrification system will now be briefly described with reference to FIG. 6. A prior art plasma arc vitrification system 10 includes a reaction vessel 12 having top 12a, bottom 12b, and sides 12c and 12d. Bottom 12b may have a generally V-shaped configuration. Reaction vessel 12 further includes at least one port or opening 14a through its top by which waste material 40 is introduced into reaction vessel 12. The reaction vessel 12 includes a plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com