Electrolytic cell for removal of material from a solution

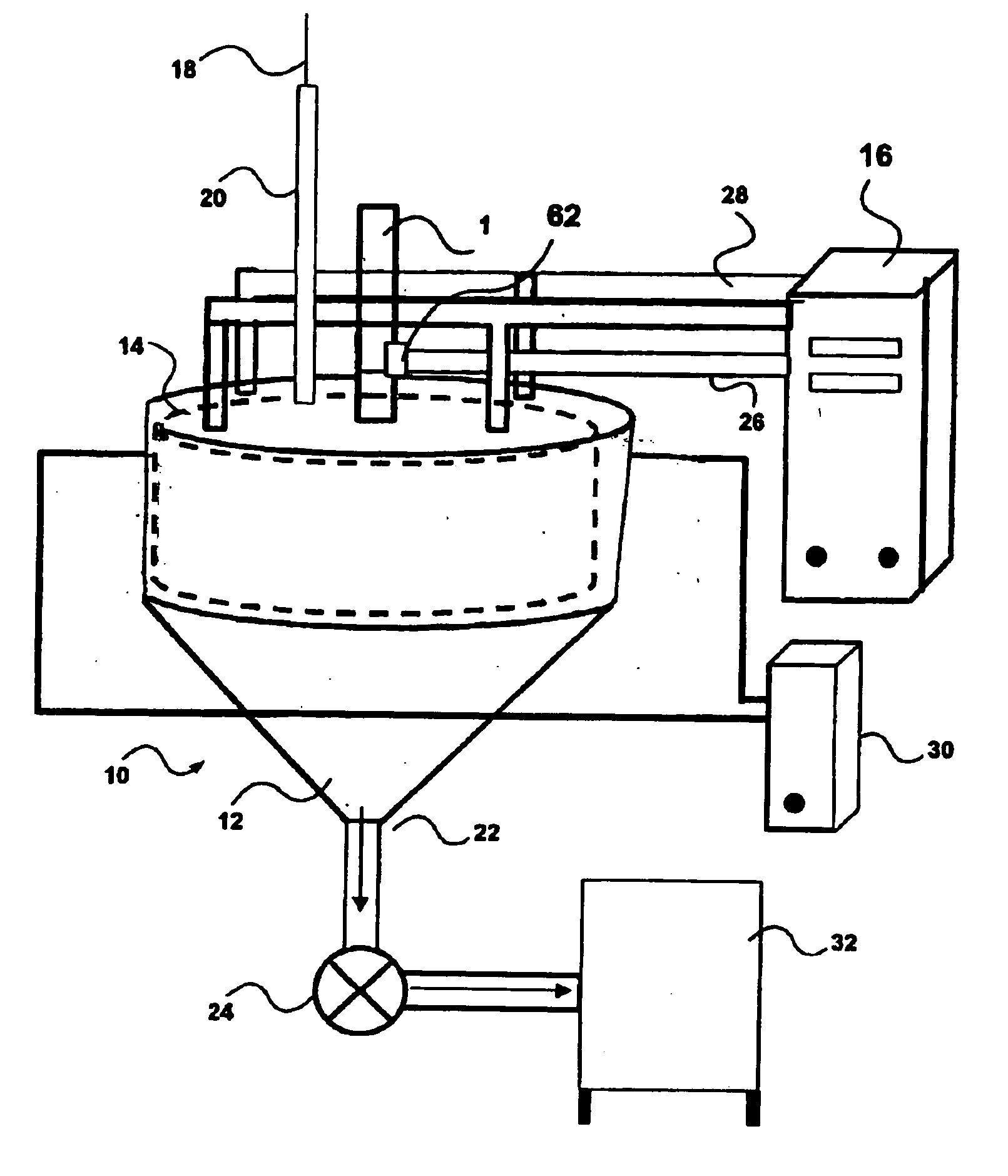

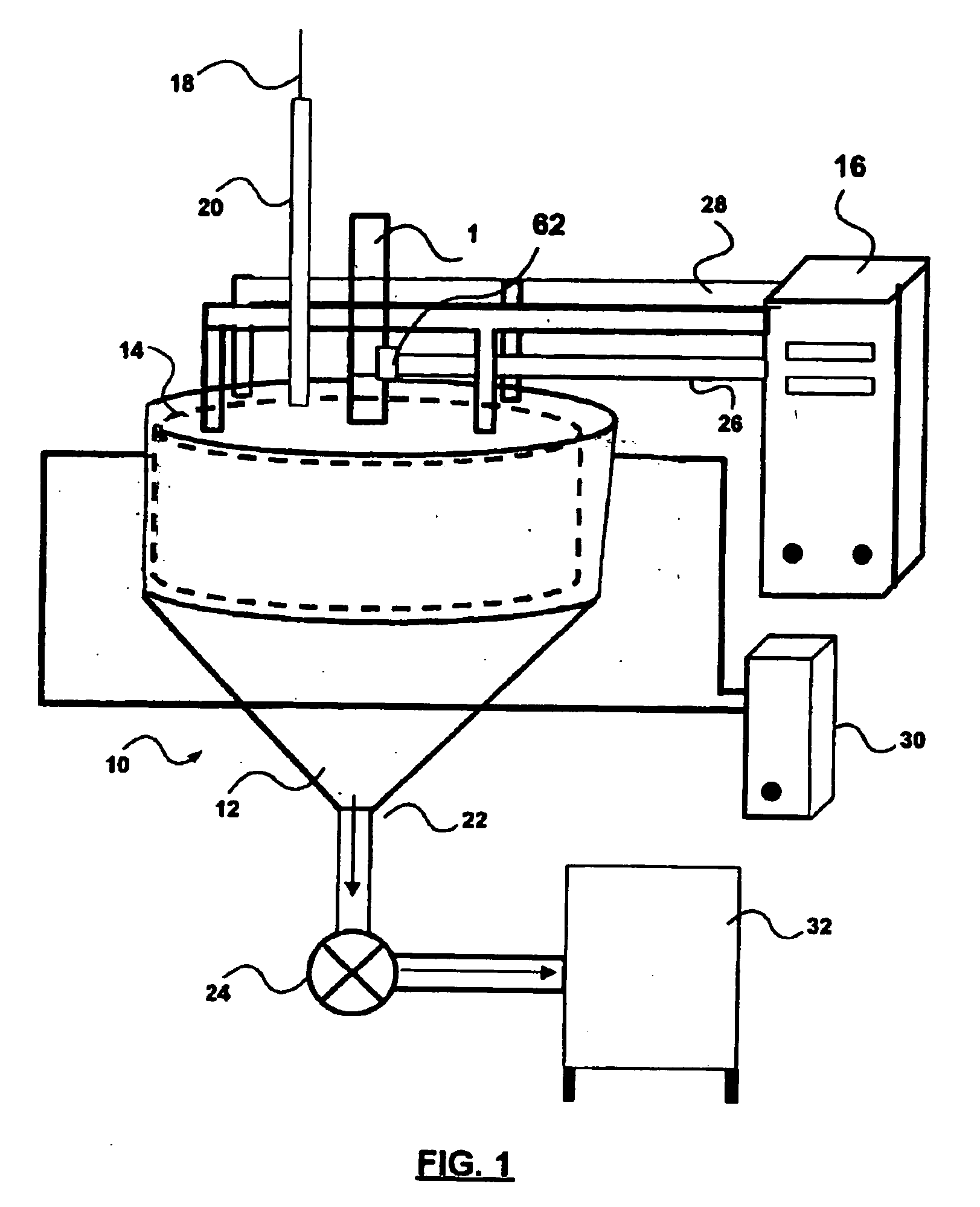

a technology of electrolysis cell and material, which is applied in the field of electrochemical methods and equipment for recovering materials from solutions, can solve the problems of increased sludge disposed on land-field, increased wear, and increased risk of breakage, and achieves the effects of reducing the size of the cell, improving throughput, and increasing the volume of material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

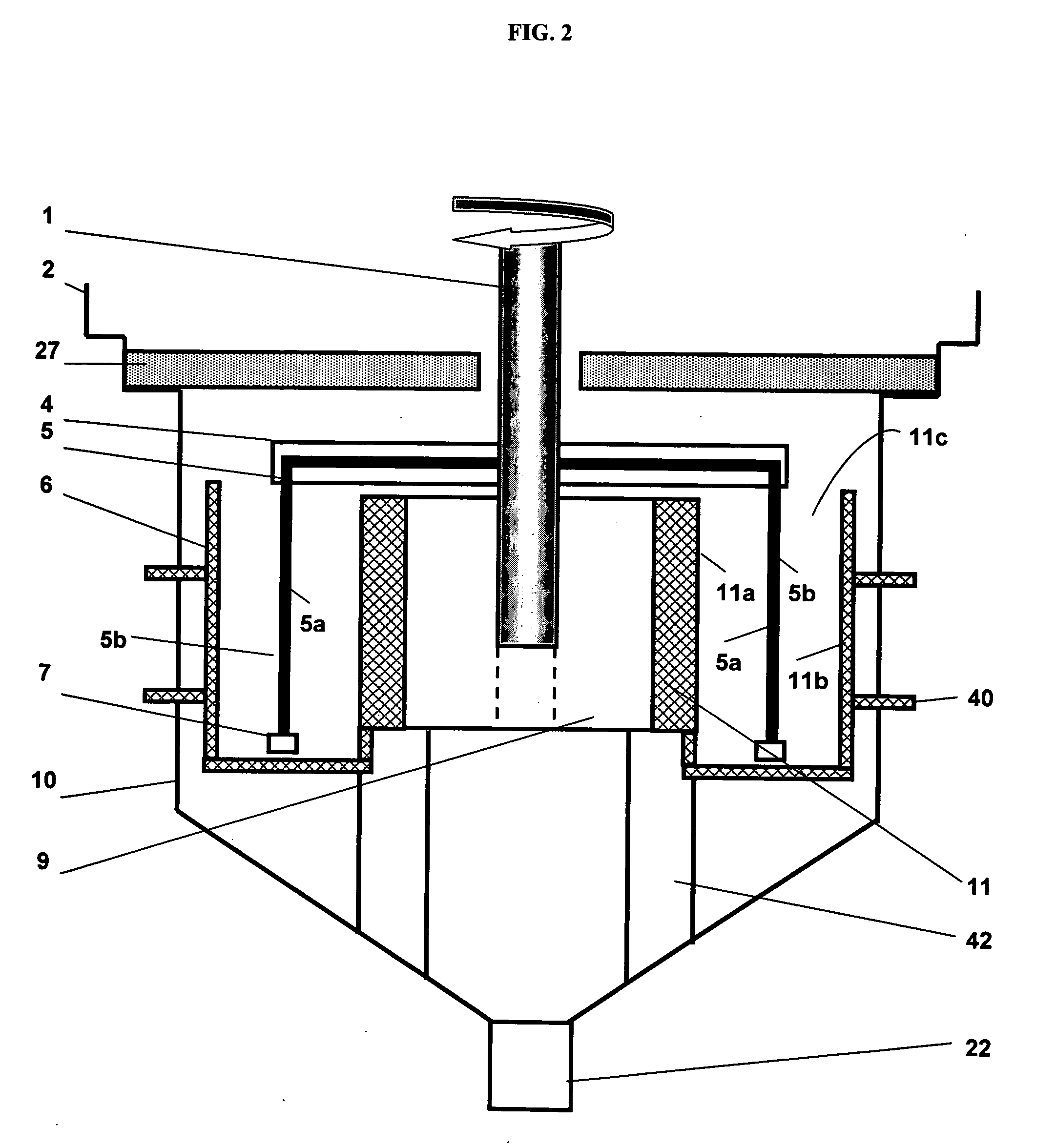

[0091] If a single-face rotatable electrode is to be design to treat for instance 40 liters / minute of a copper solution at 150 mA / cm2, the required surface of the cathode is 19635 cm2 and its diameter is 100 cm; keeping the liquid flow rate but doubling the surface area reduces the current by half; since the current density cannot be changed, the surface area can only be kept at its original calculated value by dividing by half the diameter of the rotatable electrode. Hence, the overall size of the electrolytic cell is being reduced by half when the surface area of the rotatable electrode is doubled.

example 2

[0092] If two metals such as copper and nickel are to be electrowon at respectively 150 mA / cm2 and 50 mA / cm2 and tangential speeds of 10.88 and 5.44 m / s, two double-face rotatable electrode mechanically fixed together to the same shaft but electrically isolated from one each other will required a diameter difference of 2:1 and a total applied current difference of 3 / 2:1.

[0093] The invention is more adapted to recover metals from plating processes and mining processes, but can be applied to other types of industries such as metal finishing, metallurgy, pigments and chemical additives. The recovery of metals lowers the amount of generated waste when the apparatus is installed up-stream a wastewater system, thus, reducing the amount of sludge to dispose on land-fields.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Speed | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com