Agricultural sprayer boom and method of manufacture

a sprayer and boom technology, applied in the field of agricultural machinery, can solve the problems of cumbersome and expensive repair, large manpower and time required for its construction, and the residual strain of welding tubular walls, and achieve the effect of facilitating the construction of beams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

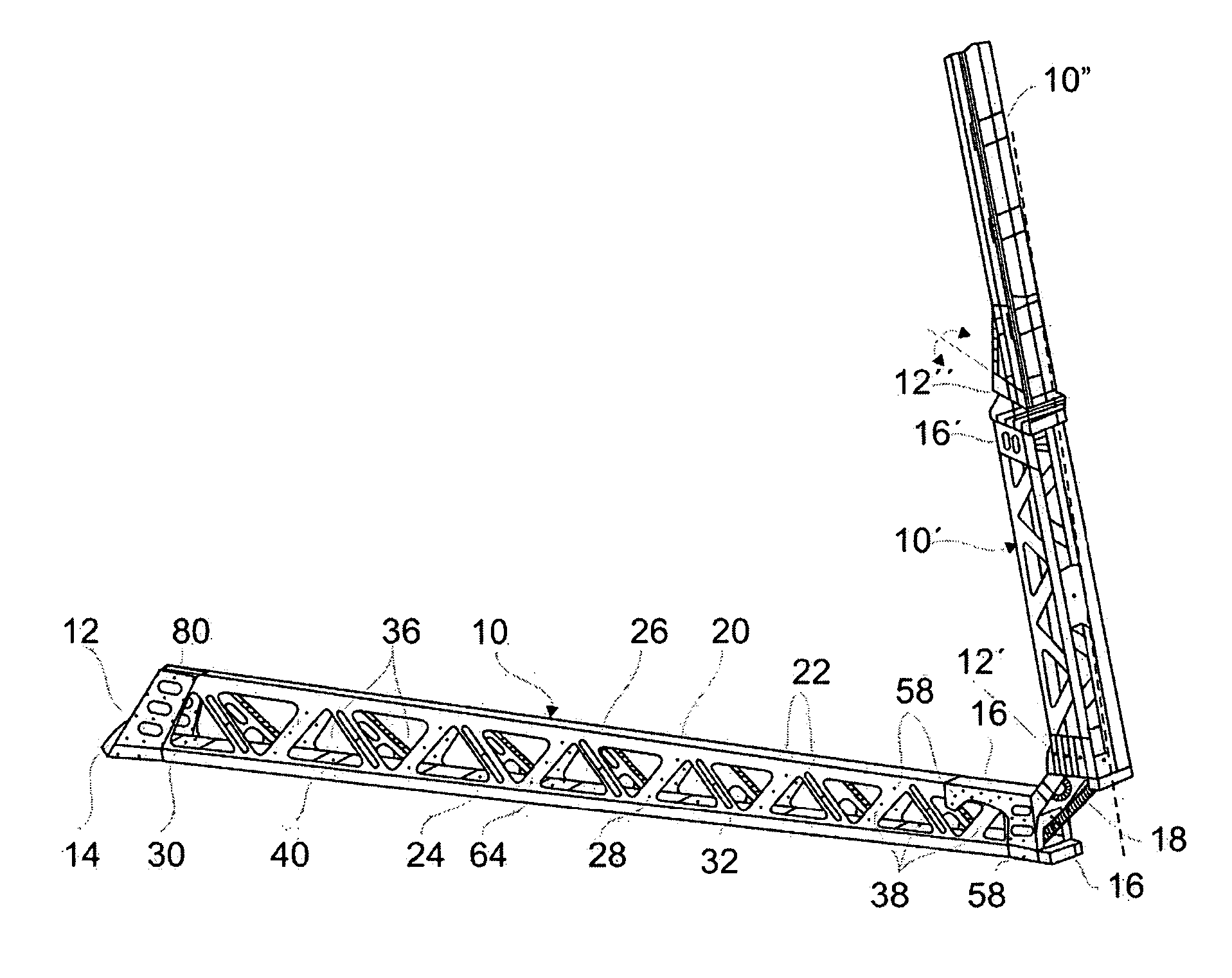

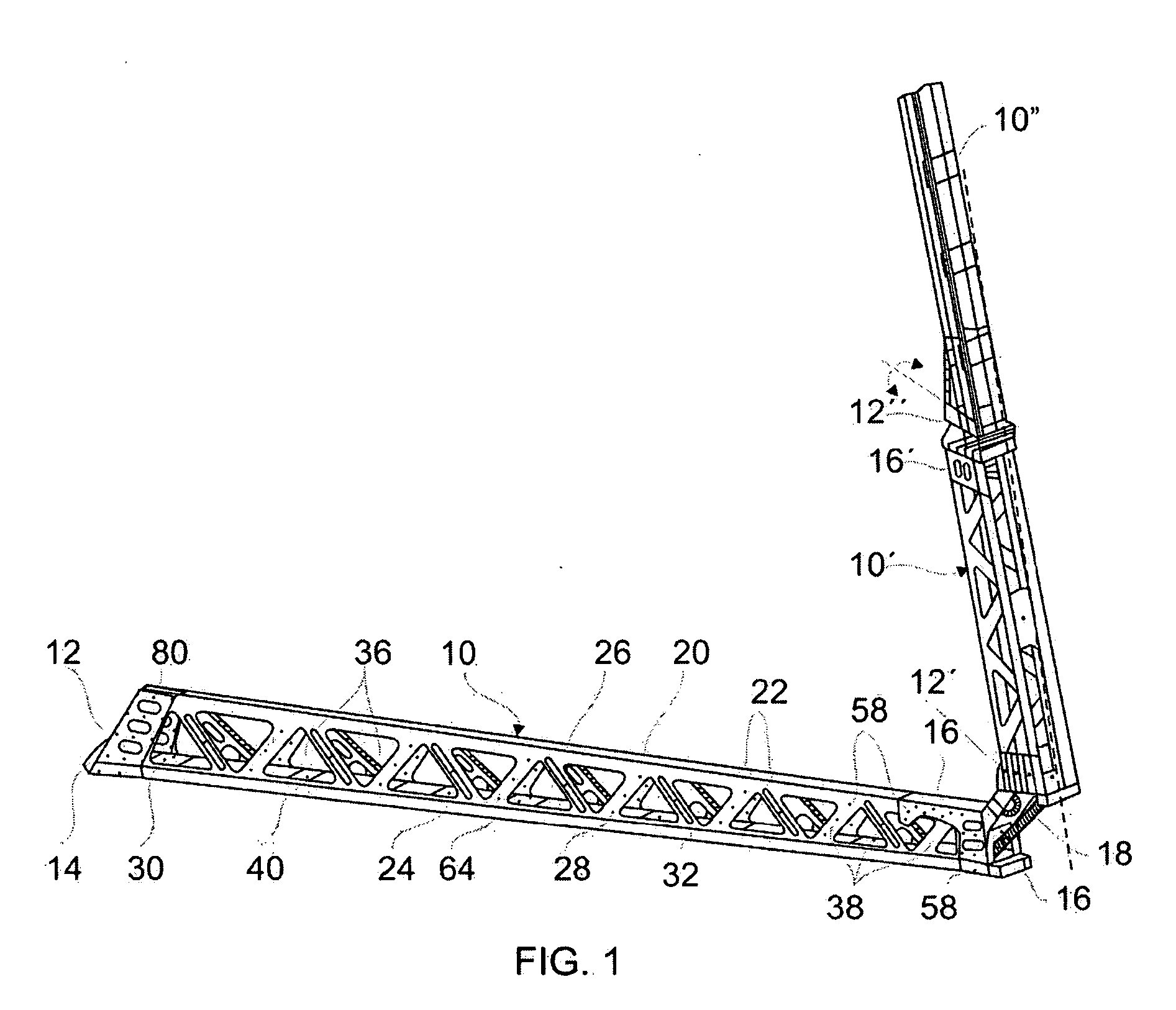

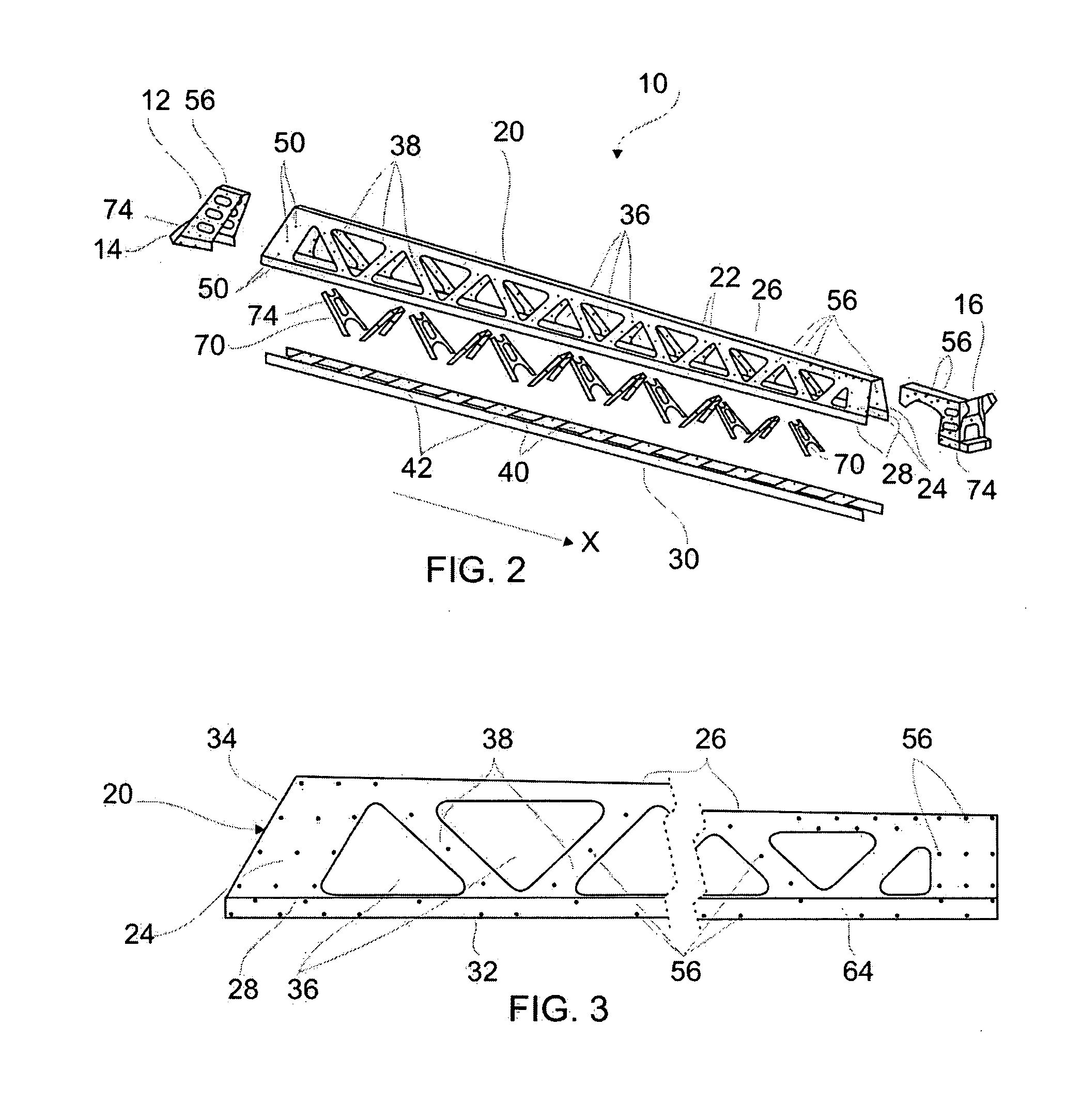

[0031] A boom according to a preferred embodiment of the invention is illustrated in FIG. 1. Two such booms are mounted, one to each side, of a sprayer machine (not illustrated) having an overall operational spray width of 25 meters and carrying a tank for 3,200 liters of spray solution. The boom comprises three beams 10-10′-10″ extending end to end in a longitudinal direction X (the longitudinal direction X of the boom corresponds to the cross-machine direction of the sprayer machine) when the boom is in its unfolded position (which is not the case in FIG. 1). The two innermost beams 10-10′ comprise elongated structures according to the present invention, although the dimensions of the middle beam 10′ are on a reduced scale in relation to the innermost beam 10 of the two. An inner cap 12 is mounted to the near end of the innermost beam 10 and is provided with hinge element 14 for mounting the boom to the sprayer machine. An outer cap 16 is mounted to the distant end of the innermos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com