Electronic device and method for fabricating the same

a technology of electronic devices and fabrication methods, applied in the direction of semiconductor devices, semiconductor/solid-state device details, electrical apparatus, etc., can solve the problems of increasing costs, affecting the thermal expansion coefficient of integrated circuit chips, and affecting the thermal expansion coefficient of saw chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

A FIRST EMBODIMENT

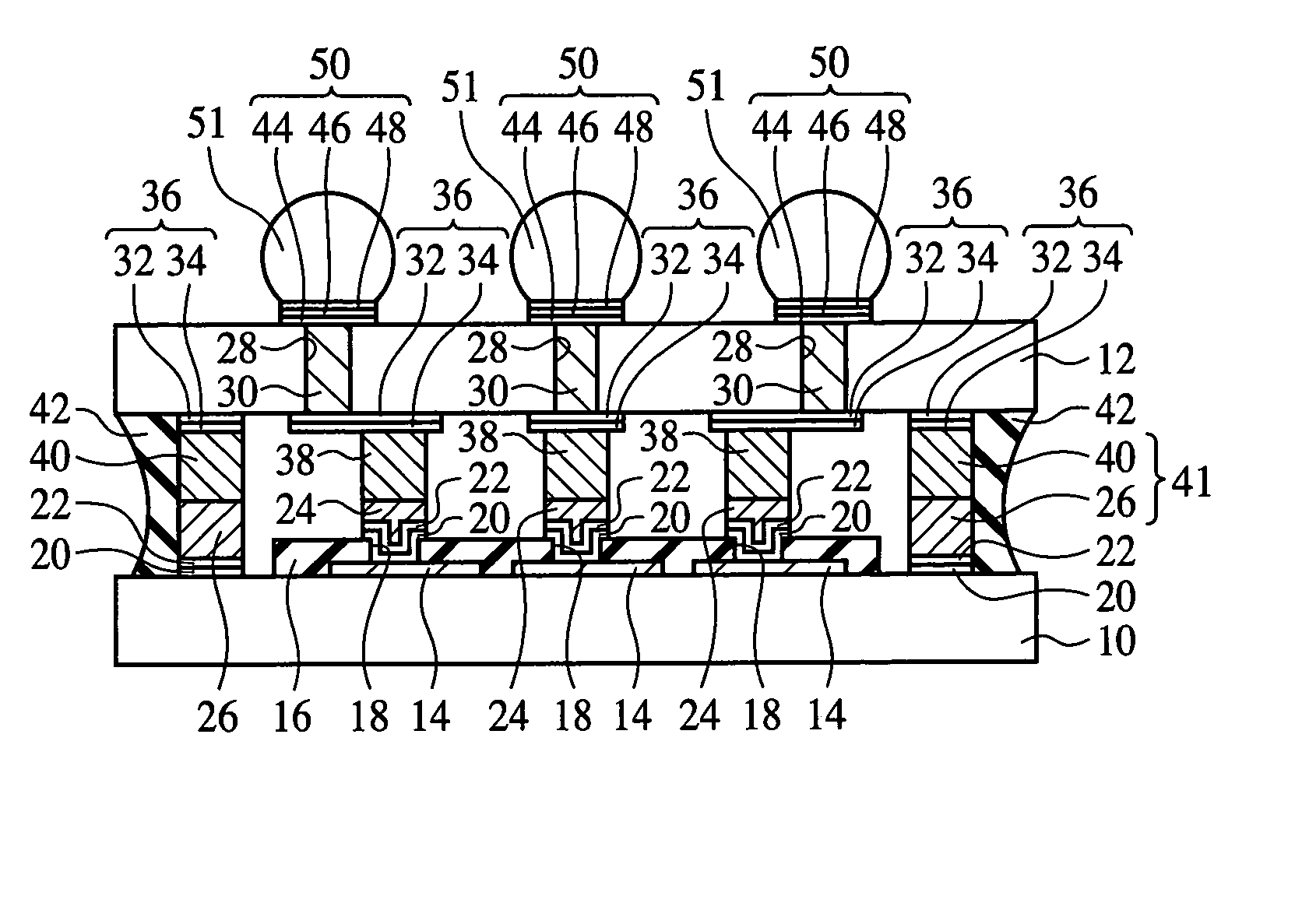

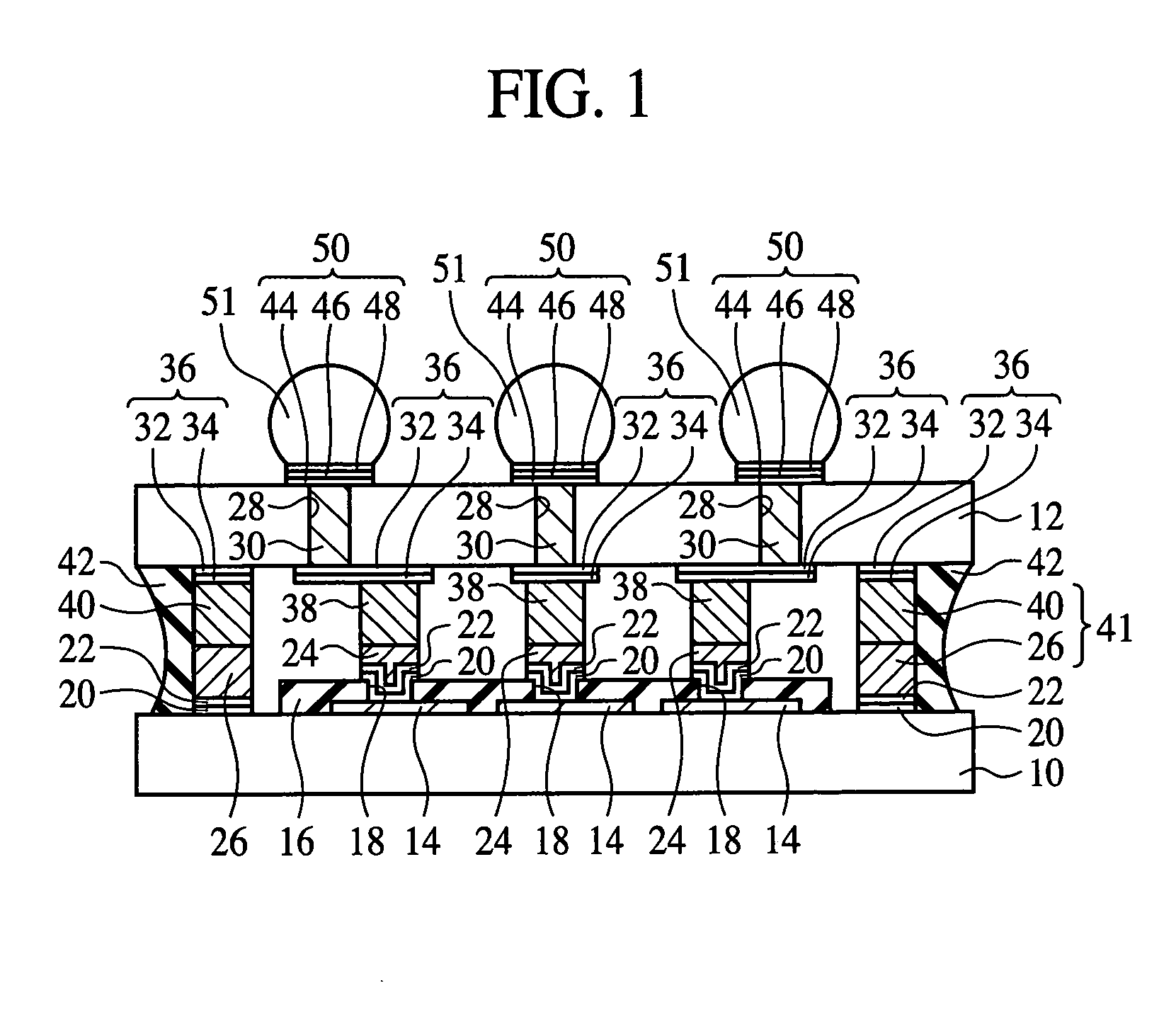

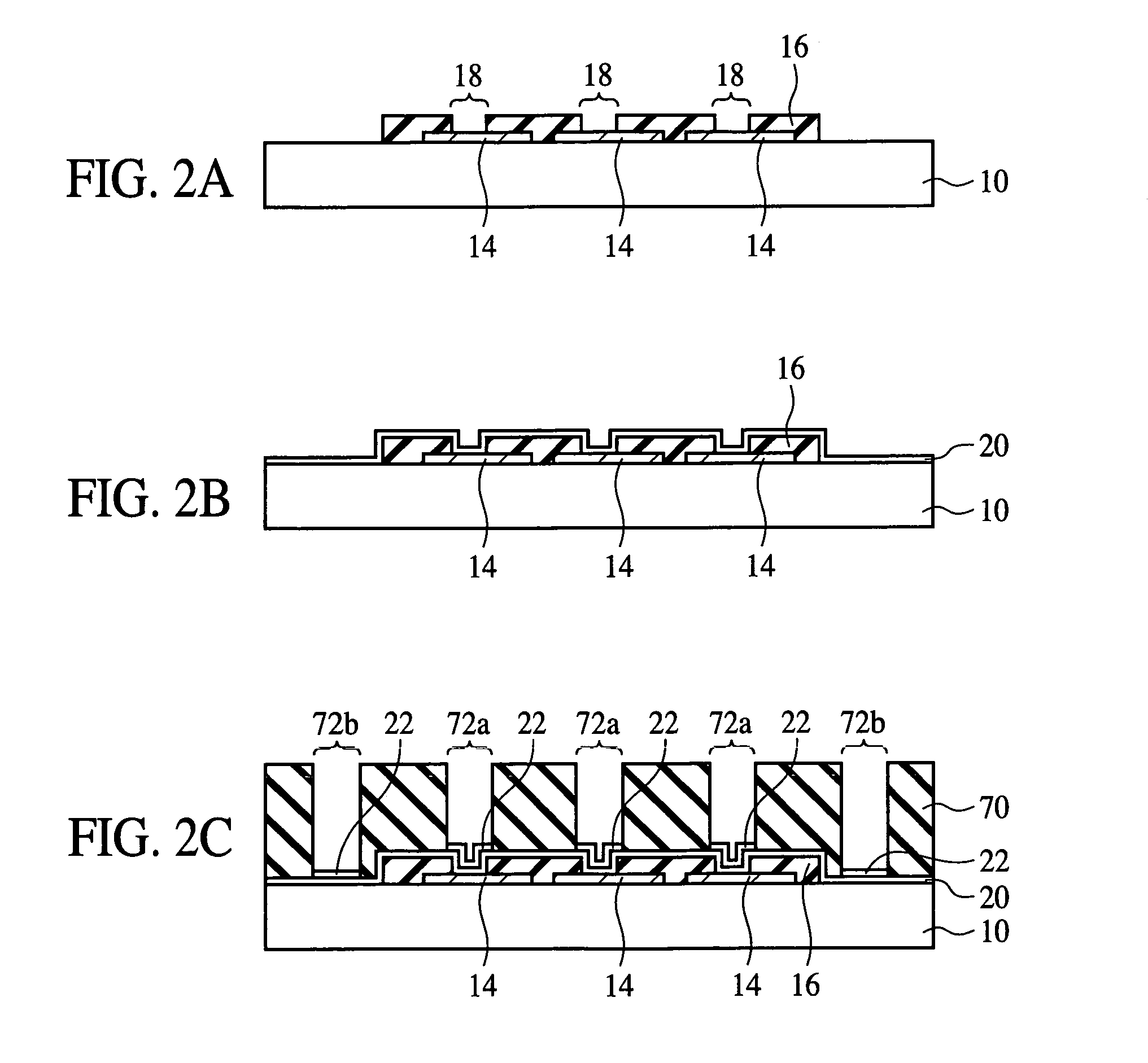

[0055] The electronic device according to a first embodiment of the present invention and the method for fabricating the electronic device will be explained with reference to FIGS. 1 to 13C. FIG. 1 is a sectional view of the electronic device according to the present embodiment.

[0056] (The Electronic Device)

[0057] As illustrated in FIG. 1, the electronic device according to the present embodiment, a semiconductor substrate 10 and a sealing substrate 12 are opposed to each other.

[0058] In predetermined regions of one primary surface of the semiconductor substrate 10, an integrated circuit (not illustrated) including electronic circuit elements (not illustrated) comprising semiconductor elements, such as transistors, etc. is formed.

[0059] That is, in the predetermined regions of one primary surface of the semiconductor substrate 10, active devices, such as transistors, etc. (not illustrated) and / or passive devices, such as capacitors, etc. (not illustrated) are f...

second embodiment

A SECOND EMBODIMENT

[0239] The method for fabricating the electronic device according to a second embodiment of the present invention will be explained with reference to FIGS. 18A to 20C.

[0240]FIG. 18A to 20C are sectional views of the electronic device according to the present embodiment in the steps of the method for fabricating the electronic device, which illustrate the method.

[0241] The same members of the present embodiment as those of the electronic device according to first embodiment and the method for fabricating the electronic device illustrated in FIGS. 1 to 17C are represented by the same reference numbers not to repeat or to simplify their explanation.

[0242] The method for fabricating the electronic device according to the present embodiment is characterized in that an adhesion layer 42b is formed on the side surface of a sealing structure 40 on the side of a sealing substrate 12, and an adhesion layer 78b is formed on the side surface of a sealing structure 26 on th...

third embodiment

A THIRD EMBODIMENT

[0282] The method for fabricating the electronic device according to a third embodiment of the present invention will be explained with reference to FIGS. 21A to 23C. FIGS. 21A to 23C are sectional views of the electronic device according to the present embodiment in the steps of the method for fabricating the electronic device, which illustrate the method.

[0283] The same members of the present embodiment as those of the electronic device according to the first or the second embodiment and the method for fabricating the electronic device illustrated in FIGS. 1 to 20C are represented by the same reference numbers not to repeat or to simplify their explanation.

[0284] The method for fabricating the electronic device according to the present embodiment is characterized in that no adhesion layer is formed on the side of a sealing substrate 12, and an adhesion layer is formed only on the side of a semiconductor substrate 10.

[0285] First, the step of preparing the semi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com