Phase change material (PCM) compositions for thermal management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

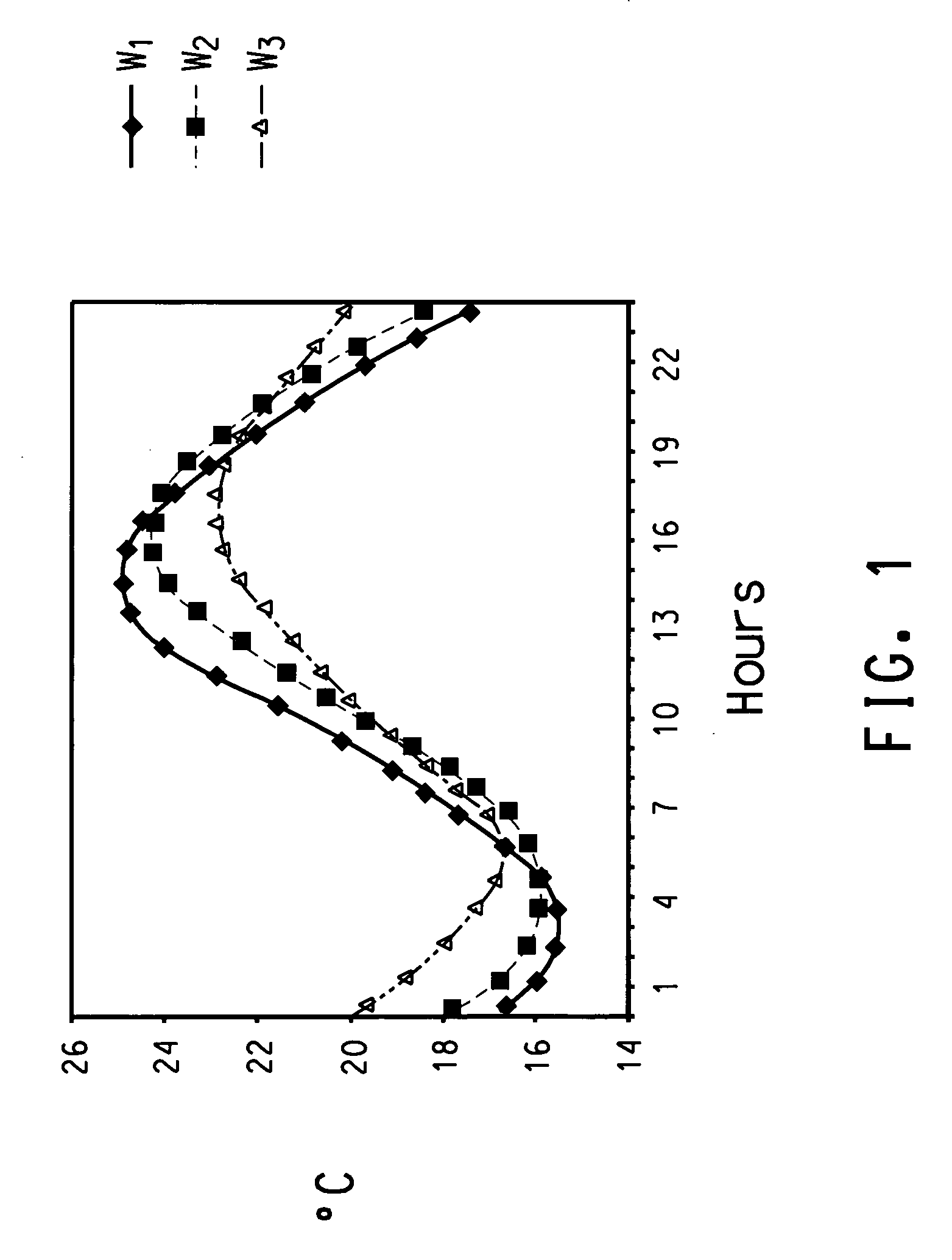

Image

Examples

example 1

[0048] 55 g of paraffinic wax (PCM) commercially available from Rubitherm under the trade name Rubitherm® RT20 (melting point 22° C.) and 45 g of granules of VLDPE (density 0.863 g / cm3) grafted with 0.5 wt % of maleic anhydride, commercially available from E. I. du Pont de Nemours and Company under the trade name Fusabond® 493 D, were simultaneously introduced into an one liter tumble blender. Blending was carried out during eight (8) hours at 25° C. in order to enable sufficient time for maximal incorporation of the liquid paraffinic wax into the polymer matrix (soaking). The granules soaked with the paraffinic wax were taken out of the blender and filtered in order to remove rests of liquid paraffin wax from their external surface. The difference in the granules weight before and after soaking was measured, thus allowing to calculate the weight percentage of wax absorbed by the polymer matrix.

[0049] Slabs were compression molded using the PCM composition obtained above. The granu...

example 3

[0054] Example 1 was repeated using granules of VLDPE (density 0.863 g / cm3), commercially available from Dow Chemicals under the trade name Engage® 8180. No slabs were made with the PCM composition obtained under this Example 3.

[0055] The results are shown in Table 2.

example 6

[0060] 44.6 g of granules of VLDPE (density 0.863 g / cm3), commercially available from Dow Chemical under the trade name Engage® 8180, were extruded, at a temperature of 220° C., with 0.4 g of a mix of vinyl-tri-methoxy-silane and peroxide catalyst (XL-Pearl® 23 commercially available from General Electric, Osi Specialities) so to obtain a blend. 55 g of paraffinic wax (PCM) commercially available from Rubitherm under the trade name Rubitherm® RT20 (melting point 22° C.), 0.03 g of di-butyl-tin-laureate and 45 g of the VLDPE based blend obtained above, were simultaneously introduced into an one liter tumble blender. Blending was carried out during eight (8) hours at 25° C. in order to enable sufficient time for maximal incorporation of the liquid paraffinic wax and di-butyl-tin-laureate into the polymer matrix (soaking). The granules soaked with the paraffinic wax and di-butyl-tin-laureate were taken out of the blender.

[0061] Slabs were compression molded using the PCM composition o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com